Constructing a box with swallowtail joints

-

Hi,

I want to make the sides of this box with my CNC lathe using swallowtail joints; the sides are 500mm high and the swallowtails should be 25mm wide.

I also need to divide the sides in height, as they do not fit on my lathe as a whole, and the parts also need to be joined together.

I have started to draw this by hand, but it is very time-consuming and complicated.

Therefore my question: Is there a possibility in SU Pro to make this easier?

Kind regards

Alohaa

-

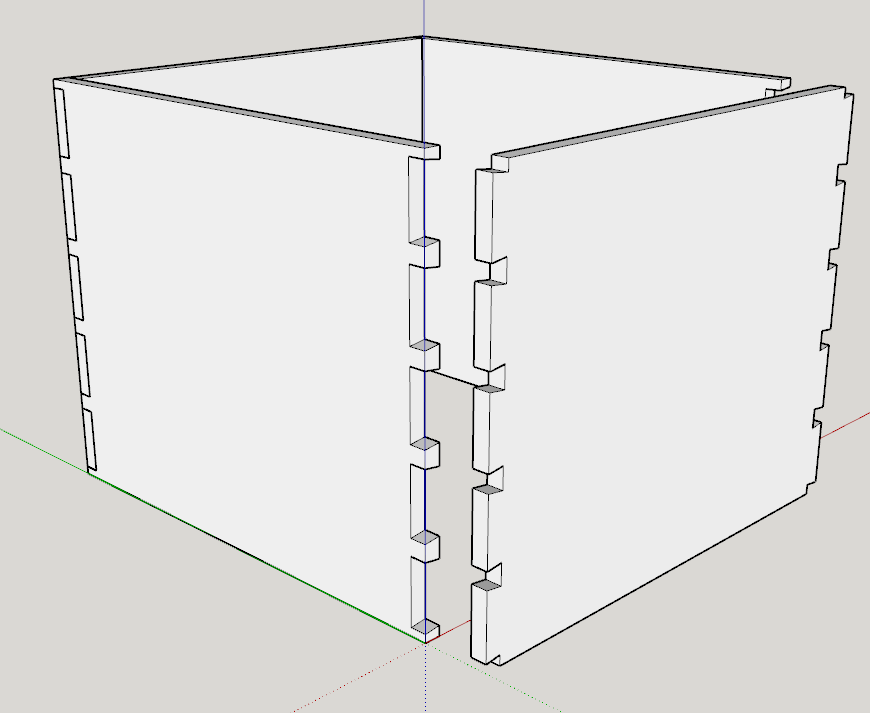

Something like this?

I used the Dovetail tool from Wudworx for this sort of thing. Quick and easy although not free.

https://sites.google.com/site/wudworx/homeIt is not marked as compatible with newer versions of SketchUp but it works just fine.

-

"Something like this?"

Yes, except that the tails should have the same dimension as the "holes", but I think that is a matter of settings!?

As I said before, I also need to divide the sides in height, as they do not fit on my lathe as a whole, and the parts also need to be joined together.

-

@alohaa said:

but I think that is a matter of settings!?

Yes. It's only a matter of settings.

@alohaa said:

The website behind the link is dated 2010! And it is only compatible with SU versions before 2020.

Read what I wrote! I told you that the website indicates it's not compatible with newer versions of SketchUp but it actually is. I added the dovetails for that screenshot using it in SketchUp 2023.

The author put that disclaimer on his site because he has not personally been able to test it in newer versions. I've been using it in every version of SketchUp since it was first released and it's worked fine.

@alohaa said:

As I said before, I also need to divide the sides in height, as they do not fit on my lathe as a whole, and the parts also need to be joined together.

How do you cut dovetails on the lathe? Model the side of the box as two different components if that's how they have to be made.

-

"Lathe" is not the correct word, I meant a CNC mill.

On the linked website the links in the Purchasing section are dead!

-

@alohaa said:

"Lathe" is not the correct word, I meant a CNC mill.

If you need to model the radii of the corners, you could use FredoSpline or Round Corner after modeling the dovetails.

@alohaa said:

On the linked website the links in the Purchasing section are dead!

No. They aren't dead. I would not have suggested the extension to you if you couldn't get it. Click on the Contact link.

-

It would also be a pretty straightforward job just using arrays, and perhaps solid Trim.

-

@box said:

It would also be a pretty straightforward job just using arrays, and perhaps solid Trim.

If I knew how to do!

@dave r said:

No. They aren't dead.

They are all dead except that one to contact the seller.

I sat down and drew simple tooth connections by hand. In fact, the true swallowtails are quite difficult to make on the mill, because there are non-rectangular angles on one side and I would have to resort to 3D machining, which is quite complicated in Estlcam, the programme I use to make the G-code.

-

@alohaa said:

They are all dead except that one to contact the seller.

That's how you purchase the extension.

-

@alohaa said:

@box said:

It would also be a pretty straightforward job just using arrays, and perhaps solid Trim.

If I knew how to do!

Its really just a matter of working out the measurements and angles needed for your specific situation.

Here I have made several assumptions which has allowed the easy use of the inference system, but you could se any sizes and angles that work.

Once you have created a pair you can use them to make more.

-

Because 'undercutting' a swallowtail corner joint is very awkward on your CNC machine you should consider alternative ways of making the corner.

e.g.- simple butt-joints or rebated laps, with dowels, biscuits etc.

- simple box-joints, where all of the boards' 'pegs' are square to the main surface.

- simple dovetail joints, where one board has dovetail 'pegs' cut square to its surface, and the mating board has simple dovetail 'recesses' cut square to its surface: there is no undercutting needed at all.

Complex swallowtail joints are either made by hand or using a different CNC machine set up, which can undercut, although with enough ingenuity you could flip boards etc to achieve this, alternative jointing is more sensible ??

-

PS:

Also, because your cutter-bit will have radius any internal corners you form with show this in reality.

Using Box's method you can easily make a component which incorporates these radii.

You then use it to subtract from the main board.

You also need a matching component to form the slots so that the radii are accounted for in those as well.

You might be better off with simple box-joints using 'mouse-ears' for any internal corners to ensure they accommodate the cutter radius ?? -

PPS:

See this example...

-

I believe Thomthom has a plugin relevant to that.

-

Thank you for your comments and suggestions.

I made these connections some time ago and you can only see the radii if you look at them from close up. They do not bother at all. And these parts are very small, compared to my current project.

I am doing this with a 3mm router, so the radius is 1.5mm, which will not bother you at all.

Advertisement