Foundation Plugin

-

I've been thinking about adding in a retaining wall feature that auto sizes the rebar and qty. based on my typical retaining wall details:

For stemwall foundations I typically check the footing width (bearing pressure) and min. rebar for shrink (ACI 318-11), see engineering calcs per this PDF:

http://design.medeek.com/resources/footing/STEMWALL_FOOTING_CALCULATOR.pdf

I could easily incorporate this type of engineering calculations into the plugin, however I'm still trying to figure out how to have the plugin output PDF reports, or Excel spreadsheets, which would be necessary if engineering reports become part of this plugin.

Same sort of thing with square or rectangular footings can be done:

http://design.medeek.com/resources/footing/SQUAREFOOTING_CALCULATOR.pdf

With stemwalls or pony walls (not necessarily retaining walls) that exceed 24" in height (but not in excess of 48") I like to add #4 bars cont. horizontal at 18" o/c. Logic could be incorporated that adds in additional stemwall and foundation wall rebar per a number of prescriptive criteria, IRC tables etc...

Currently it is entirely up to the users to specify rebar size and qty. with both stemwall and slab on grade foundations.

Stemwall foundations allow you to place rebar at the top of the wall (5" below top, qty. 1,2, or 3 bars) and rebar at the bottom of the wall (3" above bottom, qty, 1,2, or 3 bars). It also allows placement of bar in perimeter footing and interior footings (qty 1,2 or 3 bars). Bar sizes range from #3 to #8 and similar sized metric equivalents for the metric templates, I can always add more sizes if requested.

-

Nice. I hope the number of sides on the rebar and bends is not so large as to slow down SU! Might be helpful to have on a separate component and layer.

-

Some good points pbacot:

1.) I currently have the number of sides on the bends set at default value but I can easily change this to a lesser value if its determined that the file size or speed of SketchUp is becoming impacted.

2.) Layers is something I have been meaning to add into both plugins, or at least the option for layers. It would be nice to have a separate rebar layer.

3.) Currently the rebar is not grouped in any special grouping or component except for the rebar inside of interior stemwall strip footings. For those footings I have setup a component that encompassses the footing, rebar and any post/beam or studwall framing. The reason for this is the ability to copy and paste additional interior footings based on the original one. I could group all of the other rebar and mesh into its own group or component if this seems like a good idea.

-

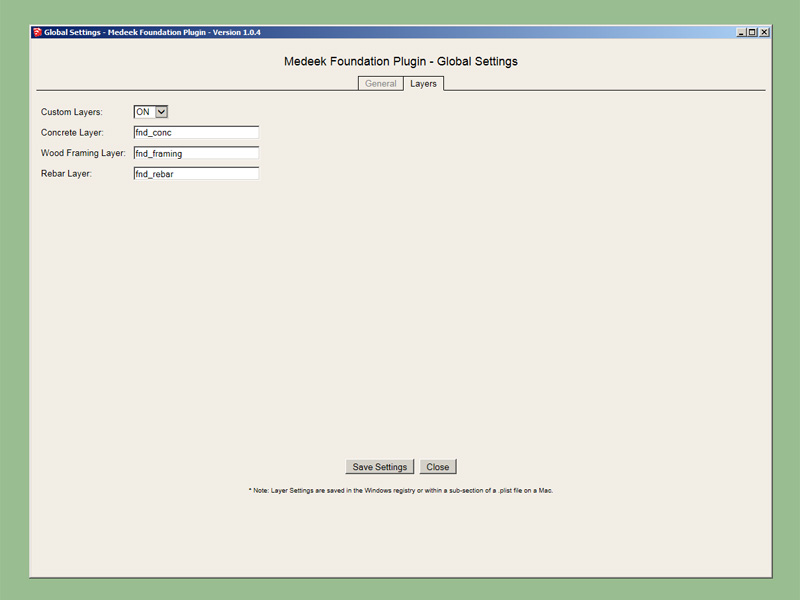

Version 1.0.6 - 12.03.2016

- Added a "Layers" tab within the global settings.

- Enabled custom layers for both stemwall and slab on grade foundations.

-

When will this plugin receive some love? Regular floor slabs not yet activated?

-

This is yet another cool plugin. Will it evolve to a slab plugin?

I just start wishing more engineers would use sketchup...

-

Floor slabs shouldn't be too hard to add, just a rectangle with some reinforcement (mesh or bar). I would also like to have the ability to have polygon shapes so the user can input in any shape. Another item to consider is integrated interior footings.

Let me know if you have any additional features you would like to see with floor slabs.

-

Looking good Nathaniel! I'm just waiting for polygon shapes for the foundations in your plugin.

-

I've been working on the polygon slab-on-grade this weekend and by extension the polygon stemwall foundation as well. The interactive "tool" portion has been difficult mostly because I don't understand a lot of that portion of the code (blackbox to me), but I'm almost there with it.

I would like to be able to create a foundation with any shape or size simply by drawing a polygon, point by point.

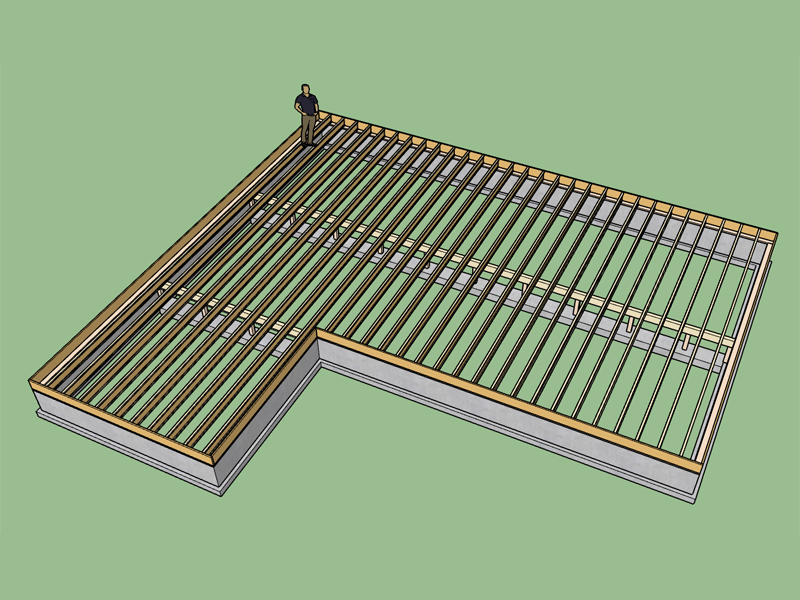

A simple example would be something like this:

Note, the interior floor beams at 12' on center. Using an Web dialog I should be able to allow the user to easily add in as many floor beams or bearing walls as required.

Once I have the foundation working correctly then I need to extend the floor truss/ floor joist module so that it can also handle polygon shaped structures within the Truss Plugin, then we will have a full package.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

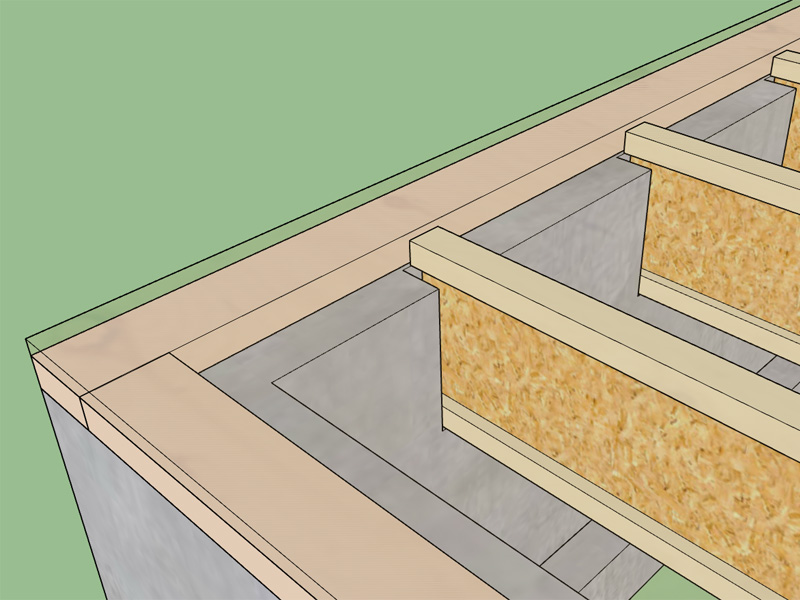

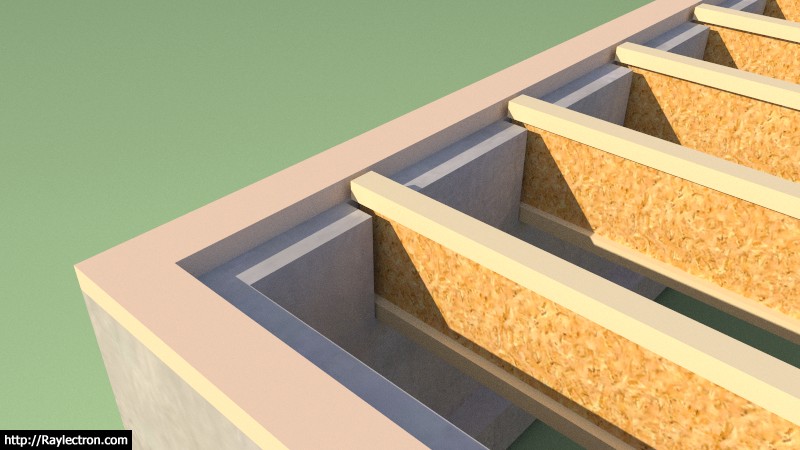

Has anyone ever seen a stemwall framed liked this?

-

Medeek,

I have placed your stem wall question in ChiefTalk which is

frequented by several active builders - designers in North AmericaChiefTalk reference:

https://chieftalk.chiefarchitect.com/topic/13289-stem-wall-detail-question-of-construction/ -

Another technique I've had a recent request on is to create slots in the stemwall that the joists sit down inside. This method dropping the joists down, even with the sill plate, seem to be fairly common in Oregon.

-

Or like this?

These two methods seem to be fairly popular in Oregon, I've never seen a floor/stemwall constructed this way any where else.

-

Looks like a lot of extra work. Why not just drop a single ledge for the joists? We do that sometimes in California. Put a pressure treated plate on a lower ledge. Also each joist needs some sort of anchoring to (but also separation from) concrete. There would be blocking, unless they use the concrete somehow.

-

@medeek said:

Has anyone ever seen a stemwall framed liked this?

No. Again, isn't blocking required at the ends of joists? I always see that.

We just pour a wider stemwall which narrows to 6" wide by the joists. If you are going to anchor 2x's at each joist, why not just anchor a continuous ledger to hang to? Again the framing looks overly complicated, but they must have a reason they are doing it that way.

-

Any thoughts on an advanced option that auto-inserts anchor bolts?

Options would be:

Size: 10", 12", 14"

Dia.: 1/2", 5/8"

Washer: 3"x3" Square, 2"x2" Square, Round

O/C Spacing (ft.): 6'

Sill Plate Thickness (in.): 1.5"

Distance from Corners (in.): 12" -

The argument for this construction method is the sheathing height is decreased because the rim board is eliminated. However, in my mind the cons outweigh the pros:

1.) There is a thermal bridge through the stemwall at the corner where the floor meets the wall.

2.) Stemwall construction would become more complicated and time consuming.

3.) Proximity of the I-Joist to the concrete could be problematic, requiring additional measures and more time and effort.

4.) The crawspace height is reduced making it harder for other subs to install and work in and moisture from the ground is more likely to be an issue.

5.) Nut and Washer of anchor bolts protrudes into floor sheathing and bottom wall plate, requiring additional notching.

6.) If you want to run plumbing or electrical down through the wall bottom plate and into the floor, this is nearly impossible with this configuration. -

Those are all good points. We use a similar method but use a single ledge. It's useful if you want the exterior concrete to come up higher due to clearance at grade or terraces alongside the wall. Sometimes there might be additional concrete wall as a sort of curb higher than the floor. You still have to make the min. crawl space clearance. Yes more hassles for plumbing and electrical. Nice option on adding anchor bolts.

-

I'm trying to determine if its easier to write a module that draws the anchor bolts or just bring in the component (pre-drawn). I've never brought in a component before so something I need to explore further. The other thing I feel is key is to make sure any of these minor components are modeled in such as way as to remain fairly lightweight within the model. No one is going to want to use a feature that bogs down their overall model. That is my one big gripe with using the 3D Warehouse models, the polygon count on most models is usually outrageous.

-

I need some input from the foundation and truss plugin users. I've decided to pre-model certain things like Bolts, Nuts, Washers etc... With Nuts and Bolts I'm planning on using a cosmetic thread so that the polygon count is minimal. As I've been experimenting with the bolts and nuts I'm wondering if I should eliminate the 30 deg. bevel on the head of the bolt and nut, it looks nice but adds quite a bit of complexity and polygons to the model. Any thoughts on this?

You would sacrifice some realism for a smaller model...

Advertisement