Problems with a half-torus

-

@teig said:

Well I bit the bullet and bought your book for the grand sum of less than a pint of beer

I've had another thought: If I made them screw together it would make it easier for assembly and disassembly. Time for a look into creating threads in SU

I've had another thought: If I made them screw together it would make it easier for assembly and disassembly. Time for a look into creating threads in SU  do I set the same kind of ~0.3mm tolerance for threads? I'll go look around.

do I set the same kind of ~0.3mm tolerance for threads? I'll go look around.Thanks!

For making threads, I'd start a little higher, like 0.5mm. You may have to tweak that after printing and testing though. You may be able to find and repurpose a model with threads from the 3D Warehouse or Thingiverse. I explain how to do that in Chapter 5.

@cadmunkey said:

Just bought it also. Looking to buy a small 3d printer soon so finding your book came just at the right time, thanks

Thank you too, I hope it helps you!

-

@d12dozr said:

Teig, I would encourage you to finish the model in Sketchup so there is no more work after 3D printing. You almost had it there once, you can do it again.

The beauty of 3D printing is a finished model, straight off the printer.

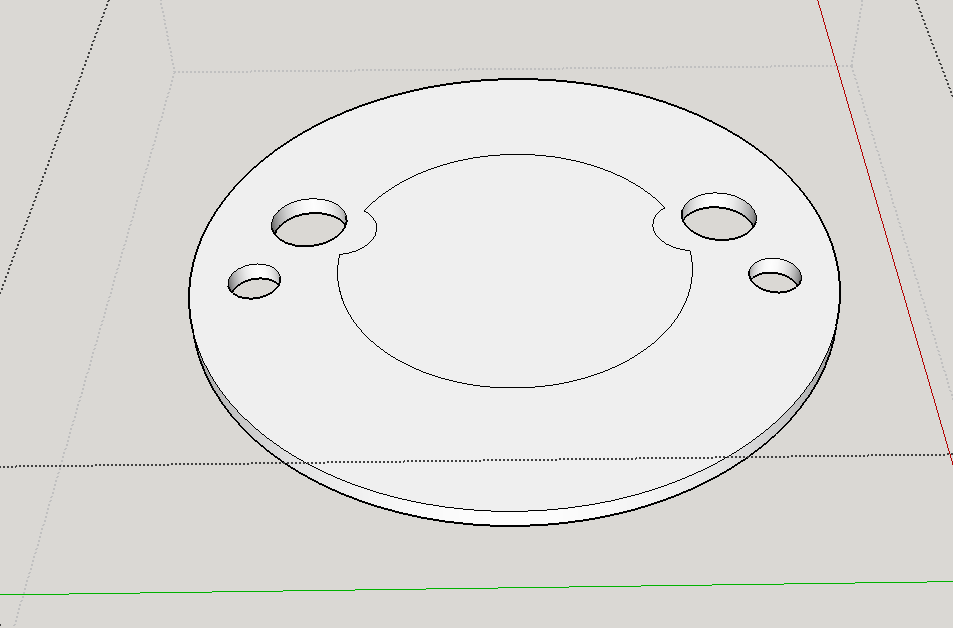

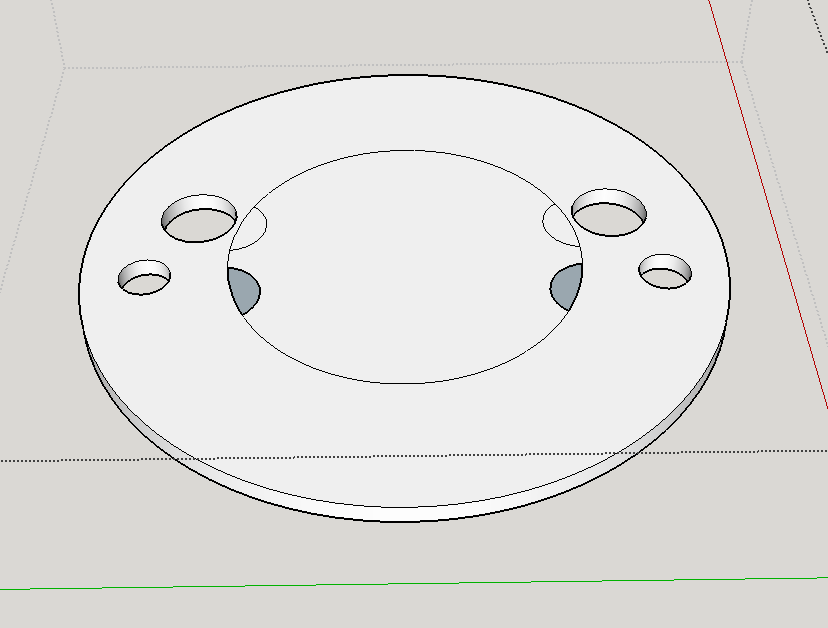

The beauty of 3D printing is a finished model, straight off the printer.I've done another 3 hours tonight putting the vents in

I was having a real problem with the push up on the [inner] vent hole intersecting the underneath of the bellmouth until I realised I'd been overthinking it

I was having a real problem with the push up on the [inner] vent hole intersecting the underneath of the bellmouth until I realised I'd been overthinking it

Then I had a fun time figuring out the scale tool, I think I've managed to restore it to 120mm outside diameter

@d12dozr said:

The gap under your bell shape is pretty small, and if it needs to be cleaned out you may be better off making the base and the bell shape in two different pieces that snap together.

If you were making this on a commercial powder printer, you could just remove the support powder with compressed air...easy peasy.

So I don't need the supporting material if I go to a commercial printer? I'm starting to think that it might be the better option.

-

A couple of things to note.

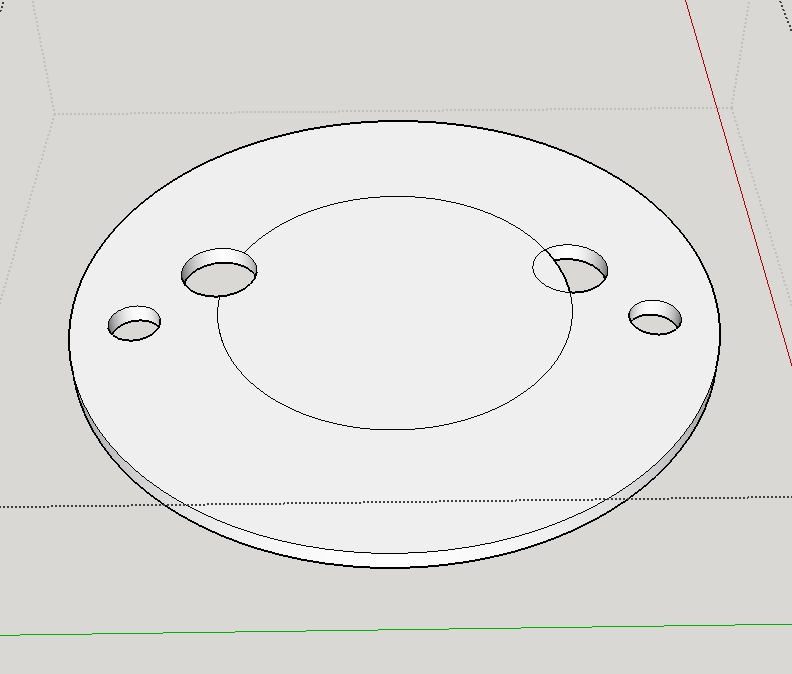

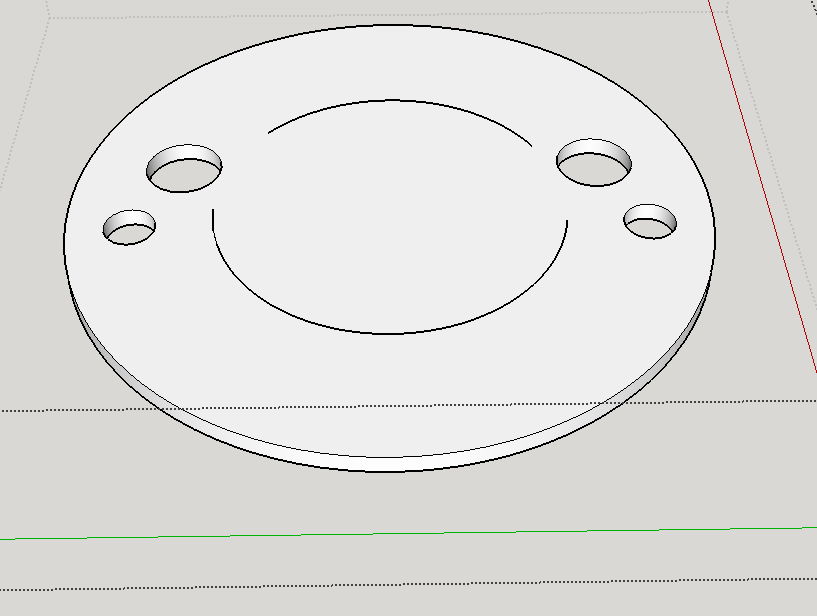

The faces inside your vent holes should be reversed, look up the hole it should be white.

I noticed your model was getting a lot of Clipping (when things sort of disappear when moving around or zooming in).

Two things are causing this and can be easily eliminated.

Your model is a long way, relatively speaking, from the origin. Working away from the origin can cause problems so it's best to stay near them as much as possible.

You must have changed the model origin at some stage too, best to reset that unless you specifically need it the way it is.

So if it was me, I would right click on one of the axes in open space and select reset. Then move your Group to that origin, explode the group to remove any possible oddities with the group origin, flip the two reversed faces and finally select all of it and make it a component. -

What is exactly this piece ? It's a real one ?

And you have no diffilculties to work with it at the initial size?

It's pasted welded? (hole disc under the girl's shoes)

-

Somehow your holes ended up in an odd position, partially showing insides of the bell shape. You know (if you need it all to be one group), you can temporarily group parts to keep them from sticking and you can hide parts easily that way. I'd group the bell portion, hide it, then clean up the rest.

I'd fill (by drawing a line on the edge) that middle hole, group, and copy it. Then remove all the lines of the hole, making a solid surface. Move your vent holes where you need them. Paste that circle back in. Explode and flip, then clean up. Or redraw that circle. It helps if you draw over the origin or have a centered guide or circle for redrawing perfectly aligned circles.

-

@box said:

A couple of things to note.

The faces inside your vent holes should be reversed, look up the hole it should be white.

I noticed your model was getting a lot of Clipping (when things sort of disappear when moving around or zooming in).

Two things are causing this and can be easily eliminated.

Your model is a long way, relatively speaking, from the origin. Working away from the origin can cause problems so it's best to stay near them as much as possible.

You must have changed the model origin at some stage too, best to reset that unless you specifically need it the way it is.

So if it was me, I would right click on one of the axes in open space and select reset. Then move your Group to that origin, explode the group to remove any possible oddities with the group origin, flip the two reversed faces and finally select all of it and make it a component.Yes, it moved from the origin when I scaled it, I had the origin bang centre at first. I don't know how to put it back right in the centre

-

@pbacot said:

Somehow your holes ended up in an odd position, partially showing insides of the bell shape

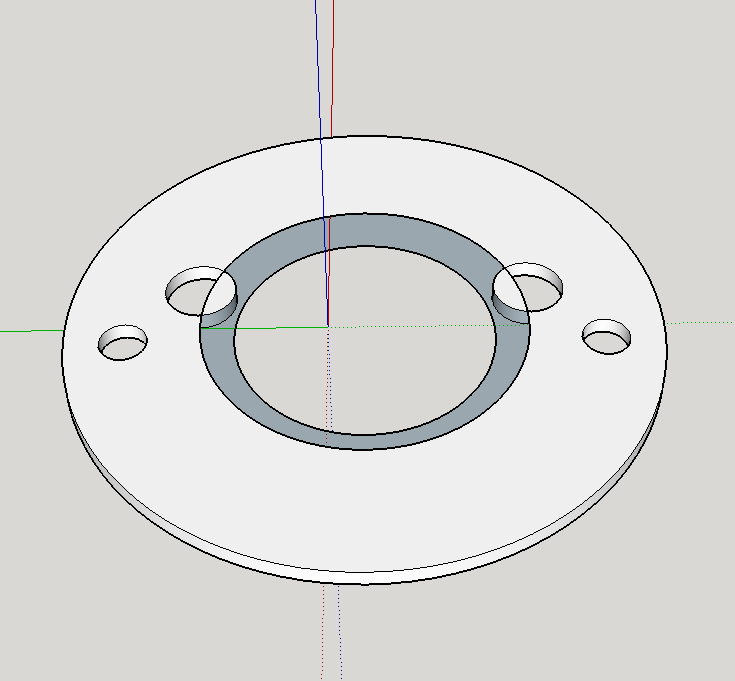

This is a bellmouth, it goes on outside of a carburettor - the rounded edges boost the adjoint of air that can be drawn in by ~6%. The two inner holes are atmospheric balance vents so have to be where they are.

-

@pilou said:

What is exactly this piece ? It's a real one ?

And you have no diffilculties to work with it at the initial size?

It's pasted welded? (hole disc under the girl's shoes)[attachment=0:q0dj7w24]<!-- ia0 -->curious.jpg<!-- ia0 -->[/attachment:q0dj7w24]

Sorry Pilou, I'm not sure you mean by "pasted welded". It's not too bad to work on at that size (even using the track pad on the Macbook Pro (I don't have a mouse)), it was no easier to work on when I multiplied it to 100x.

-

@teig said:

@pbacot said:

Somehow your holes ended up in an odd position, partially showing insides of the bell shape

This is a bellmouth, it goes on outside of a carburettor - the rounded edges boost the adjoint of air that can be drawn in by ~6%. The two inner holes are atmospheric balance vents so have to be where they are.

So it's a case of reversing those two little faces. I get it now, I guess.

-

@teig said:

@box said:

A couple of things to note.

The faces inside your vent holes should be reversed, look up the hole it should be white.

I noticed your model was getting a lot of Clipping (when things sort of disappear when moving around or zooming in).

Two things are causing this and can be easily eliminated.

Your model is a long way, relatively speaking, from the origin. Working away from the origin can cause problems so it's best to stay near them as much as possible.

You must have changed the model origin at some stage too, best to reset that unless you specifically need it the way it is.

So if it was me, I would right click on one of the axes in open space and select reset. Then move your Group to that origin, explode the group to remove any possible oddities with the group origin, flip the two reversed faces and finally select all of it and make it a component.Yes, it moved from the origin when I scaled it, I had the origin bang centre at first. I don't know how to put it back right in the centre

Edit: fixed my axes now

-

Sub Stack11v6solidFinal.skp

@pbacot said:@teig said:

@pbacot said:

Somehow your holes ended up in an odd position, partially showing insides of the bell shape

This is a bellmouth, it goes on outside of a carburettor - the rounded edges boost the adjoint of air that can be drawn in by ~6%. The two inner holes are atmospheric balance vents so have to be where they are.

So it's a case of reversing those two little faces. I get it now, I guess.

I tried reversing the faces of the holes but they just went darker (indicates the inside I understand) so I'm not sure what to do?

Sub Stack11v6solidFinal.skp -

No, I meant this bit.

-

@teig said:

(I don't have a mouse)

Buy a cheap 3 button mouse, the type with the scroll wheel as the third button immediately. You will never look back. You can zoom/orbit/pan all at the same time while using other tools.

-

@unknownuser said:

it was no easier to work on when I multiplied it to 100x.

First: SU don't like these mini measures because operations between volumes generally fall!

(cut, boolean diff etc)Second: When you use a render this one takes many more time than with more normal unites!

That was the case for your object!

Third: try to import your object in an existing scene!

@unknownuser said:

"pasted welded".

In the reality how these 2 parts are built? Fondry ? (except the 3D Printing)

-

@box said:

No, I meant this bit.

Thankyou Box, well spotted

I have sorted those out.

I have sorted those out.I then tried to save it as a solid but the entity info says it a Group(1 in model) I ran SolidSolver and it reported this:

**SolidSolver:

The Selected Group is still NOT 'Solid' !

77 Unfaced/Coplanar Edges Removed

0 Holes Healed

0 Small Faces Healed

26 Partition/Flaps Removed

0 Split-Edges Merged**Clicked on the 'yes' to get them removed and then this message:

**SolidSolver:

This Group/Instance can never be solved into a 'Solid'!

Try manually adding/removing Edges/Faces...

[Undo if appropriate]**I'm afraid I'm not sure how to find these edges and faces in order to delete them

-

Use a combination of Xray mode and SectionPlanes to 'look inside' the object.

You can select a face and press <delete>, or [where it's not 'destructive'] use the Erase tool to delete unwanted edges and related faces.To reiterate what was said several times before...

A 'solid' object cannot contain anything but geometry [guides are acceptable BUT best avoided]

That geometry consists of edges and faces.

Every edge must have exactly two faces associated with it.

No fewer, no more.

So that means...

No faceless edges.

No edges with only one face - e.g. around a 'hole' or forming the edge of a 'flap' or 'shelf'.

No edges with more that two faces - e.g. internal 'partitions' where some edges have three or more faces, or two otherwise solid-looking forms [like two cubes] sharing a 'common edge' - so that some edges have four faces !

No overlaid faces - this is rare, but sometimes two faces 'that ought to auto-merge into one' continue to exists and so their edges then have extra faces too !In your case the SolidSolver messages suggests multiple 'internal partitions'.

If these are too convoluted, then deleting one might then compromise what's left and so result in no solution...

In that case only a manual fix suffices...

My algorithms [aka 'brain'] isnot up to solving some of the complex balls-ups which you users can contrive !!

-

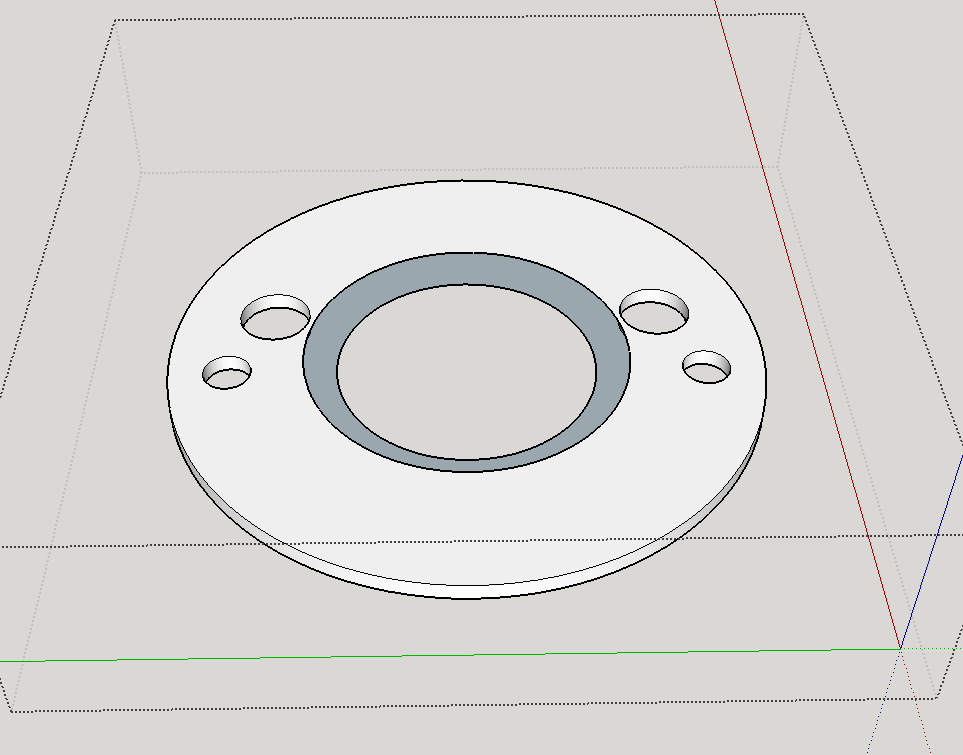

Teig, two of the holes on the bottom are causing the problem, as pointed out in the following image.

If you pull those 2 faces down a fraction of a mm and clean up the resulting internal faces, the model becomes solid.

@teig said:

So I don't need the supporting material if I go to a commercial printer? I'm starting to think that it might be the better option.

For a part with this complexity, you'd be better off. Something like Shapeways Strong and Flexible (S&F) plastic should work well. BTW, since this is a part for a carburetor, how hot would the piece get? Shapeways S&F melting point is ~180C.

ABS from a desktop printer melts at ~200C.

-

@tig said:

Use a combination of Xray mode and SectionPlanes to 'look inside' the object.

You can select a face and press <delete>, or [where it's not 'destructive'] use the Erase tool to delete unwanted edges and related faces.To reiterate what was said several times before...

A 'solid' object cannot contain anything but geometry [guides are acceptable BUT best avoided]

That geometry consists of edges and faces.

Every edge must have exactly two faces associated with it.

No fewer, no more.

So that means...

No faceless edges.

No edges with only one face - e.g. around a 'hole' or forming the edge of a 'flap' or 'shelf'.

No edges with more that two faces - e.g. internal 'partitions' where some edges have three or more faces, or two otherwise solid-looking forms [like two cubes] sharing a 'common edge' - so that some edges have four faces !

No overlaid faces - this is rare, but sometimes two faces 'that ought to auto-merge into one' continue to exists and so their edges then have extra faces too !In your case the SolidSolver messages suggests multiple 'internal partitions'.

If these are too convoluted, then deleting one might then compromise what's left and so result in no solution...

In that case only a manual fix suffices...

My algorithms [aka 'brain'] isnot up to solving some of the complex balls-ups which you users can contrive !!

I'm sorry if it doesn't sink in quickly... Your explanation there is useful - a bit more 'plain English' that I can understand

-

@d12dozr said:

Teig, two of the holes on the bottom are causing the problem, as pointed out in the following image.

[attachment=1:1wvyo62i]<!-- ia1 -->Capture.JPG<!-- ia1 -->[/attachment:1wvyo62i]If you pull those 2 faces down a fraction of a mm and clean up the resulting internal faces, the model becomes solid.

Thank you very much once again d12dozr.

I pulled those faces down by 0.03mm, grouped it again, it reported back as a group sigh . I exploded it again, pushed the faces 'up', it wanted to snap to .04mm so I left it, did the other one. Drumroll It reported back as solid!!!

I pulled those faces down by 0.03mm, grouped it again, it reported back as a group sigh . I exploded it again, pushed the faces 'up', it wanted to snap to .04mm so I left it, did the other one. Drumroll It reported back as solid!!!

@d12dozr said:

@teig said:

So I don't need the supporting material if I go to a commercial printer? I'm starting to think that it might be the better option.

For a part with this complexity, you'd be better off. Something like Shapeways Strong and Flexible (S&F) plastic should work well. BTW, since this is a part for a carburetor, how hot would the piece get? Shapeways S&F melting point is ~180C.

ABS from a desktop printer melts at ~200C.

You pre-empted my next question

Either of those two plastics should be fine then, I can't imagine it getting over 180C even in traffic on a summer's day? The venturi will constantly pulling cool air over it as well.

[attachment=0:1wvyo62i]<!-- ia0 -->Sub Stack11v6solidFinal.skp<!-- ia0 -->[/attachment:1wvyo62i]

-

Great! It's a learning process, and you're getting a crash course

Advertisement