Building thickness

-

One of them is attached.

They are just faces. I was told to 3d print them they have to have wall thickness.

Or is there a way for me to make them solid (so not void in middle like SU draws)

-

Shellify seems like it might do the opposite of what I want. The problem is a 3d printer wont print just a "shell" or just faces with no thickness

If you you do the reverse faces with a smaller building does it make walls for you?

-

These are simple blocks. Shellify might do it Also you could scale the building making a smaller version inside. Reverse the faces. You will have to push in projections that still sit outside after scaling.

How do you intend to print? Is the creation of walls just to make it empty inside (not visible in the end product?) the the second procedure above might work.

Reading your second post-- if these can be solid material, then printing would fill the form you have shown.

-

Sorry I am probably not explaining very well.

A 3d printer will not read just a face in SU even in the faces are closed, like a cube. It does not read the cube as a solid......at least thats what i have been told.

-

@rudbeckia said:

... Or is there a way for me to make them solid (so not void in middle like SU draws)

Normally when 3d printing you are charged for the amount (cm3) of printing material you use. If you make everything massive solids it will cost you a lot.

Making shells might be better. Just watch out the roof spans are not too large (ask the 3d printing service for their specs) or the material will need some kind of support structure to keep the roof in place.

-

The "shells" need walls though correct? Meaning they cant just be faces?

Im wondering if there is a quick way to make walls from a bunch of buildings that are just faces.

-

[quote="Rudbeckia"]Shellify seems like it might do the opposite of what I want. The problem is a 3d printer wont print just a "shell" or just faces with no thickness

What I describe would be making inside faces spaced in from the outside. You reverse the faces on this inside group so that the space "inside the walls" is then all back faces.

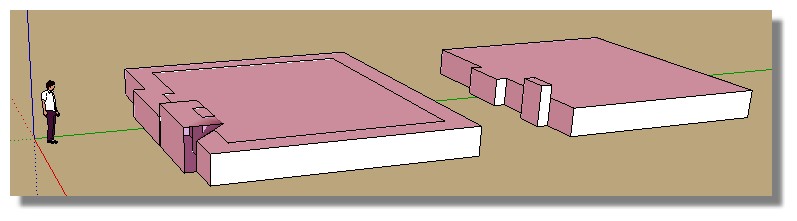

I'll attach the model. The wall thickness in this scale method are not exact. You have to adjust to your liking after.

I don't know of a fast way myself.

-

I see now what you are saying, so the bldg you attached would print on a 3d printer? Even though it is still faces not walls? Bc what you have done would be a lot faster than redrawing all the sides of the bldgs as walls

-

OK. As I understand, it will. I don't do 3d printing myself, but I have helped others with models to print, and it came out fine. SketchUp only has faces. However a properly made model will print when translated.

The point about the roof span should be considered you might end up adding some columns or other mass in the center to keep it from sinking in. Probably you should pushpull it thicker than I show too (roof and floor). A prototype model would help your printer tell you what is needed.

-

thanks for the help!

-

A quick addition to my earlier comment:

- you could also just offset the floorplane and pushpull it up just below the rooflevel.

- if you make a group of a closed object it will automatically turn into a solid. You can only 3d print solid objects

- check the specs and material of your 3d printer. it will depend the minimall thickness of the walls and roof and if you need supporting structures for the roof.

- check your units. If you want to 3d print the model at some scale, the model should be scaled accordingly.

-

@kaas said:

A quick addition to my earlier comment:

- you could also just offset the floorplane and pushpull it up just below the rooflevel.

- if you make a group of a closed object it will automatically turn into a solid. You can only 3d print solid objects

- check the specs and material of your 3d printer. it will depend the minimall thickness of the walls and roof and if you need supporting structures for the roof.

- check your units. If you want to 3d print the model at some scale, the model should be scaled accordingly.

No 1 is a good idea. Faster.

-

@pbacot said:

OK. As I understand, it will.

It's depending on the printing technology. If it's powder based for example, you need escape holes for the powder inside... for some ideas of rules see here.

You need to follow the design rules for the specific printer that will be used! (wall thickness, holes, ...)

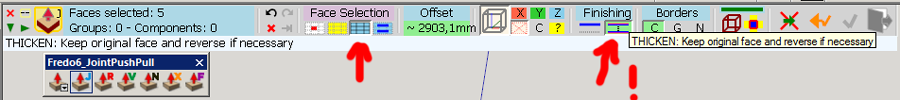

A quick way to add thickness to the walls in this case could be the JPP plugin from Fredo, and to make it into a solid component use Solidsolver from TIG...

[screenr:3mtb2nbb]YSUN[/screenr:3mtb2nbb]

-

@Cotty

How select the faces on this video ?

Does the background external faces of the 2 "little boxes" are selected?

Have you a screenshot of the JPP toolbar regulates? -

Does this screenshot help?

-

-

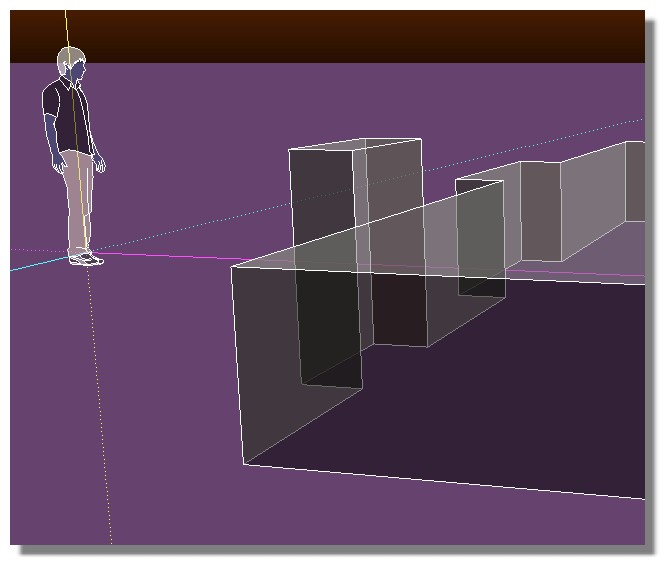

I've got the same problem with your geomtry...

-

I believe that your geometry works because your 2 little boxes are "penetrating" by the top inside the big one!

Mine is just "pasted" without soaking even inside is effectively dug!

So maybe Fred must improuve his JPP!

-

@rudbeckia said:

A 3d printer will not read just a face in SU even in the faces are closed, like a cube. It does not read the cube as a solid......at least thats what i have been told.

I've not had that problem. When you have a closed volume, in SketchUp it will say "Solid" in Entity Into then it's good to go for 3d print.

This was printed from a SketchUp model:

https://plus.google.com/u/0/photos/103450081381233788032/albums/5754245713469640065

I used iMaterialize's services.

-

Poor pawn !

Advertisement