Cool tool -- thanks for creating and posting it, TIG! The more I experiment with it, the more impressed I become.

As a SketchUp newbie and a Mac user, I request that TIG please add the description of the correct Mac plugin folder location to the install instructions in the main post. I initially put my install in the wrong place. The menu items still showed, though I couldn't get them to work. (That may be because of my inexperience, rather than a limitation of the plugin.)

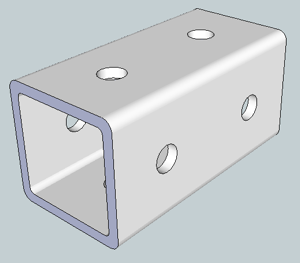

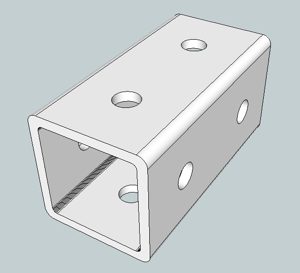

It took a bit of experimentation before I achieved components that punched through. I'm sure TIG's instructions are clear to people who know SketchUp better than I do. For the benefit of other newbies, here's how creating a punchable component seems to work in its simplest form:

- Use any drawing tool(s) to create a surface (circle, rectangle, doodle...). You can do this on the object you wish to punch, or elsewhere.

- Select the surface and delete it. This will leave you with a set of bounding lines.

- Select the bounding lines. (On a Mac, use the Select tool and double-click one of the lines. Unless you deleted a line and created a gap, this will select them all.)

- Select Make Component.

- In the dialog box, change the "Glue to:" selection from None to another option.

- Check the "Cut opening" checkbox.

- Make sure "Replace selection with component" is checked.

- Optional: give your component a descriptive name.

- Click "Create."

- If necessary, position your component using the Move tool.

- Select the component and right-click (Windows) or Option-click (Mac) to pop up a contextual menu.

- In the contextual menu, select Hole Punching... > Punch

If the bounding lines of your surface would be hard to select separately from the object you are punching (for instance, if you created a rectangle that shares an edge with the object you want to punch), make a component from your surface and its bounding lines by skipping Step 2 above. After creating your component, edit it by double-clicking it with the Select tool. Click the surface to select it, delete it, then close your component. You are now ready to punch a hole.

If you don't remove the surface from your component, the plugin WILL punch the hole... but you won't see it because the surface will hide it. Orbit to the other side of the object to see your hole.

Did I get that right, TIG?