Follow-me twist problem

-

Hi,

I am usually able to solve most issues that I come across by googling and reading the many helpful post here, but I have been unable to find any solution to a problem I have with the follow-me tool. I have SU 2016.

I am trying to model a shaped wedding band. In the file I've upload (follow-me-problem.skp). There is the path of the wedding band shape and a simple rectangular profile. If I start the follow-me with the profile at the top of the path the extrusion expands on one side due to the follow-me twist, and if I start the profile at the bottom of the path, the extrusion contracts on one side.

After lots of hunting and reading I tried, Upright-Extruder, Follow-me And Keep, and 1001bit Tools (which I cannot get to work properly). None of these correct my problem. Has anyone any thoughts?

Many thanks.

Sud

-

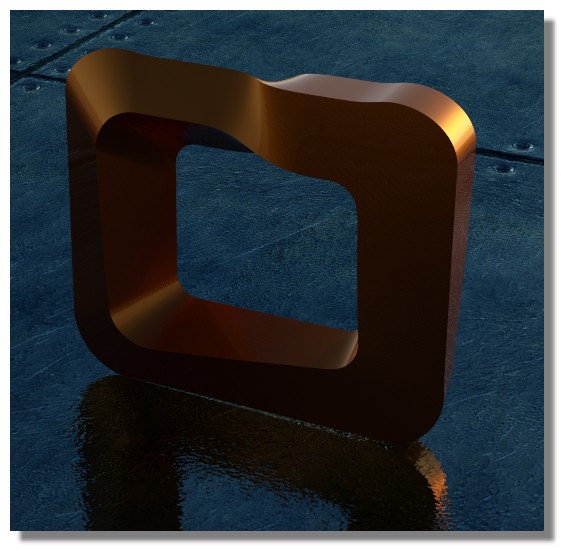

Is this the sort of shape you are after?

If so a small investment in vertex tools would stand you in good stead.I've just re-read your post and I'm not sure I understood what you needed, but it's very late here and I'm off to bed.

-

@box said:

Is this the sort of shape you are after?

[attachment=1:m75ps08f]<!-- ia1 -->Vertex.gif<!-- ia1 -->[/attachment:m75ps08f]

If so a small investment in vertex tools would stand you in good stead.I've just re-read your post and I'm not sure I understood what you needed, but it's very late here and I'm off to bed.

Thanks for the reply Box.

I have the Joint Push Pull extension wich does what have done, but it's not quite what I'm after. I hope the attached file will illustrate more clearly what I'd like.

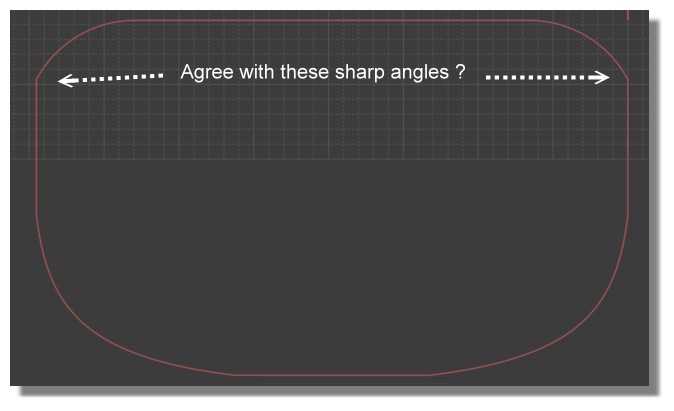

At the top you can see a 2D example of the vertex option. Below it is what I'd like. It's more like the offset tool. Below these you can see what happens with follow-me. The extruded profile (x-section) turns/twists as it progresses along the path. So the diameter of the front of the ring (the finger size) is larger than the diameter of the back of the ring.

I hope I have explained it better.

Thanks.

Sud

-

Just rotate 180° the rectangular surface that is not working ? (by it's gravity center)

But can you post an image of Start / Target volume wanted ?

PS Fill your personal profil, it's more easy for to help you...

-

Have you tried upright extruder on their backs?

What about Extude edge and Joint push pull?

True bend would be another option.

-

Can't reload your last skp ! (save as 2016 as previous)

-

A set of very interesting approaches.

-

Don't forget you can always 'remove the finger' from the ring.

-

I am sorry, just did not quite understand you there so here is my try on this.

At first, I only can get to offset that curve if the upper surface is planar.

So I first did JointPushPull on that upper surface to get a straight hight surface and then used

that surface to get a straight upper surface.

Then I used that surface and JointPushPull-Follow Push Pull to get high surfaces that are offsetting from the upper one.

Here is a file also because my explanation sounds weird, just a bit

I reupload the file, now it is the SU20016 version.

-

If you have not the pro version for Boolean operations you have Bool Tools 2

(powerful than native tools) -

More Good videos Box and Pilou. Thanks for sharing.

-

@pilou said:

Can't reload your last skp ! (save as 2016 as previous)

Hi pilou,

The last skp I uploaded (follow-me-problem-2.skp) was in 2016 format

-

Wow!

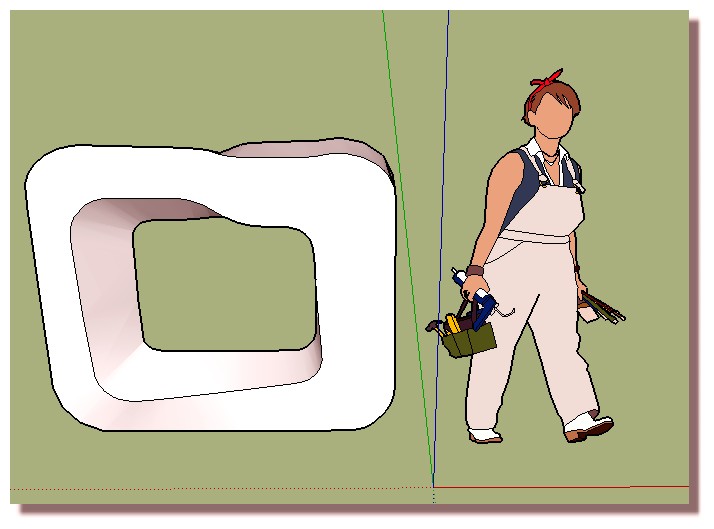

I kind of owe you all a little apology. The rectangular profile was super-simplified to illustrate the problem. I realise now that the impacts any solutions you guys may post. The actual profile I want to use is this:

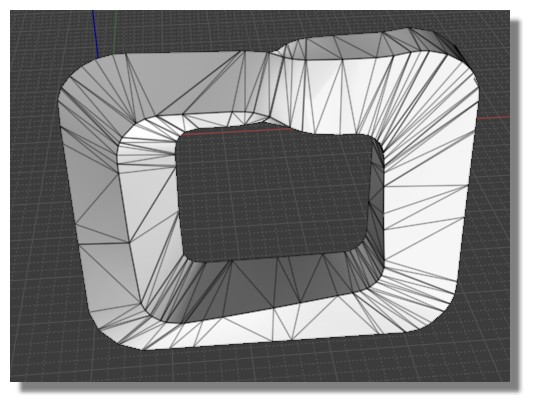

Box; As I mentioned in my initial post, I tried Upright Extruder. It produces results much like the vertex option. It's good, but not perfect. The edge-extrusion/joint-push-pull produces similar results too, and also, I don't think that option would work with the profile I need. True-Bend is a great suggestion. After "flattening" the ring rail/path using the Unfold tool, producing a flattened complete ring using follow-me and the profile, and then using True-Bend, I'm getting exactly what I need.

The only issue I'm having now is the final solid isn't the "solid" that's needed for 3D-printing. There are many errors that Solid-Inspector finds. I know this is due to the high resultion I need to get a good final result when the ring is actually cast. I'm experimenting with scaling up before True-Bending. Hopefully that will solve the solid issue.

Thank you all for your input, suggestions and solutions. They've been v helpful and have reduced my headache

-

And why not use Curviloft for propagate some profils on rails?

-

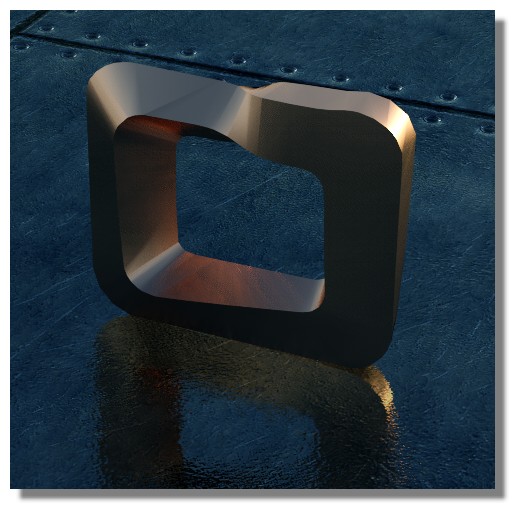

And the winner is ... Curviloft

Excellent solution pilou. Thank you v much. The perfect shape and a perfect solid with no complex intersections to fix.

Should fit snuggly against this lovely little Edwardian engagement ring.

Thanks again, everyone.

-

If you are doing a lot of jewelry it would be well worth your time to look into using vertex tools and true bend. It makes it easy to create rings from non symmetric geometry. And you can be as detailed as you need as long as you model cleanly. This required no cleanup after the bend except the removal of the double inner faces at the join. I only used 96 segments but you can easily go to the 200 you were using if need be.

-

Hi again,

Upon closer inspection, although the solidness is good and the profile alignment is good along all of the "straight" section of the rail, using Curviloft, the profile does twist on the shaped part of the rail. Back to TrueBend and solid-fixing. Scaling up x1000 reduced the errors to only 3 ... phew.

Just thought you might like to know.

-

Maybe we can try something...

Post the file of Profils and Rails in dxf format and let see that Moi3D (nurbs) will made as result in SKP format export......not sure...of the result

(it's not your file just a test)

(it's not your file just a test)Here the structure of export SKP

Reloaded in SU

I must ask more polygons in export!

(rendered as SKP file)

(rendered as SKP file)

This time edges are perfect! (for an SKP file)

-

-

Next version of Moi (V4) will be more adapted for erase problems of the DXF!

Another thing : i must reduce the number of Control Points of the curves!

Or even redraw over it...

(Whithout change the form of course! )

Advertisement