Foundation Plugin

-

If there is enough room between the footing and the slab I could see how one could omit the stemwall and have a layer of gravel, sand, soil between the slab and the footing at the opening. I have never seen a slab poured that way at the garage door opening but it doesn't mean it can't be done. I supposed one could even go so far as omit the footing across the opening as well but from a structural standpoint I would highly discourage that, much better to tie the building foundation together at the perimeter with regard to lateral loads.

-

Option 1 is what I have used many times. Never the others. Frost depth 2 to 3 feet typically.

-

The blockout methods seem to be all over the board, I've even talked with some of my engineering friends and the response is mixed there as well. I guess I just need to provide the option for any of these three configurations within the plugin. Sometimes I feel that I get bogged down in the details but I hope some of this level of detail is appreciated.

The other issue I'm having with slabs within garage spaces is the slope of the slab. I'm trying to determine if is worth trying to incorporate a slope into the slab as it would actually be poured. As far as I know there is not a minimum slope specified for garage floors in the IRC 2015 or earlier only this fairly general statement:

[highlight=#ffffcf:1d83tmnb]The area of the floor used for parking of automobiles or other vehicles shall be sloped to facilitate the movement of liquids to a drain or toward the main vehicle entry doorway.[/highlight:1d83tmnb]

Typically the garage slope is 1/8" per foot or 1:96, how critical is this to you the user of the plugin? Flat would be easier to program but then your blocked out entries on the side of a garage would be only theoretical.

-

A few observations ...

- In residential construction here in central California the norm is to pour the garage slab monolithically with the footings. Some builders will pour the footings and stems first and then come back with the garage floor slab, but there aren't many. Our frost depth is very shallow.

- My preference for sloping of the garage slab is to have a 3-1/2" drop at the top end below the residence's finished floor slab and sloped down to 5-1/2" at the garage door end.

-

My feeling about slopes is that I absolutely want to model them. There are a lot of instances where having the real slope gives you valuable information with regard to the actual construction. A case in point would be - What is the real height of a deck beam. I would rather have this information on the drawing or model rather that having the carpenter figuring it out on the jobsite.

With respect to garage slabs, I usually have the slab 2" min below the adjacent house floor with a 2" slope from the back of the garage to the garage door. -

And where do you set the floor height from. Usually I end up working out what is best at the rear of the garage and sloping from there.

-

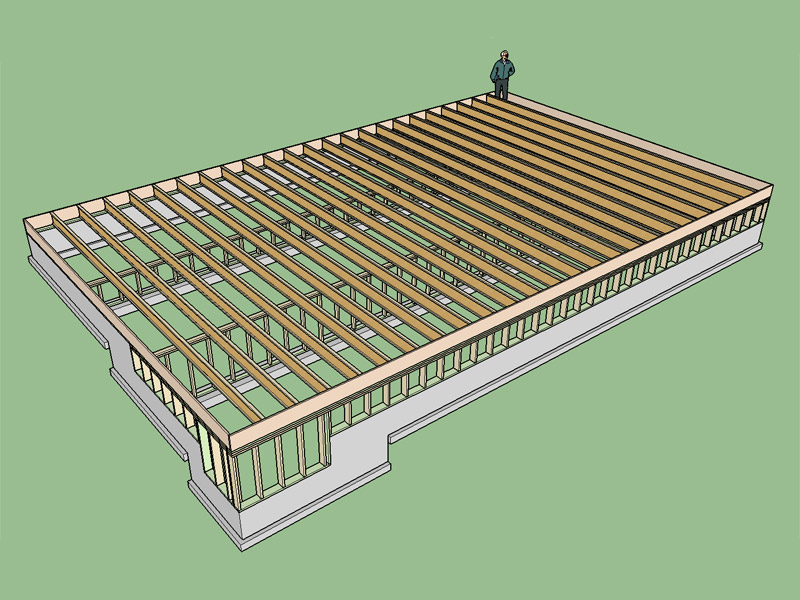

Here is a quick study on a garage slab that slopes 3" over about 24':

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

What to do with the slope at the garage door? I've flattened it out but that leaves a line in the slab.

At the side door entrance the right side of the slab is about 3/8" higher than the left side. Entrances that are parallel to the slope will have this property (problem?).

At the rear of the garage the slab is 6" below the top of the foundation and at the garage door it is 9" below the top. Perusing through different plan sets I've collected over the years this seems pretty typical for the slope (1/8" in 12").

I think I should probably make the slope an option so those that want to model it can.

Rather than make the slope a percent grade or degrees I think it would be easiest to let the users specify a total rise or drop for the entire slab.

-

I was playing with the Dibac plugin a little bit today and I really like the wall creation tool or how it works when selecting the 2D wall layout. I think I can program something like this for stem wall creation (polyline) that would allow the user to select any random stem wall layout. I've pretty much got it worked out already but I'm trying to figure out how to do that little trick with the tab key which allows the user to toggle the wall justification. Any hints would be appreciated.

-

I've been investigating attributes today trying to get a better handle on this aspect of SketchUp. I've noticed that the housebuilder plugin creates a category called "einfo" and stores a number of variables one of which is the "origin". If you manually move the wall group the origin attribute will automatically reflect this change in location. This is exactly the feature I need for my various assemblies (groups) so that I can add an edit feature. Howevever, I can't seem to figure out how this attribute is automatically updating. When I create an "origin" attribute under a "einfo" category it does not update. I must be missing something.

-

Try asking those questions in the develops section, I'm sure someone there would be able to point you in the right direction. Most visitors (including me) that frequent this section (and others) would not be able to even comprehend what you're referring to.

-

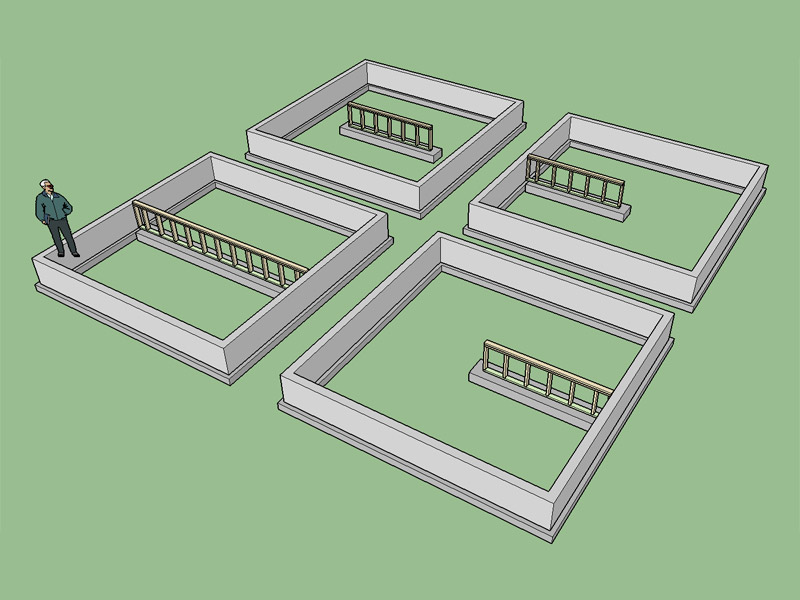

The current home designer I am working for likes to use 2x4 bearing walls versus a post and beam system in their crawl spaces:

I am wondering how common this method is and if it is something I should add into the foundation plugin as another variant.

-

Crawl Space - Access

Suggest an "access opening" in the stud spacing for any future inspection or maintenance.

Centre location would be logical, miss one stud and design support for floor joist. -

For a stud wall your right you need access doors or openings. I will make another function that lets one place the opening after the fact, that way they can be located by the user.

-

Does anyone have any details showing the access door through a strip footing and bearing stud wall. I have one here but I would be interested in seeing what others use so I can determine the most popular way of framing this up and then implement it.

-

What I've done in the past (and seems to work the best) is simply frame it as a door opening (36" or 48") with a 4x4 (or 4x6) with the top flush with the double top plate.

-

Something like this?

-

Medeek,

I am curious about the "white" membrane, is there to be a concrete slab poured?

If so what was the construction sequence?

If it is a moisture barrier how is it protected? -

Nathaniel -

Yep, that's basically it (though I've also see the top plates lapped into the header as well).

-

Version 1.0.3 - 08.28.2016

- Enabled interior bearing wall(s) with strip footing.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

I still need to enable the ability to add framed openings into the interior stud walls. Interior stud/bearing walls can be created with single or double top plates and can be full span or partial spanning as shown in the image above.

Also note that the studs are aligned from the right side of the stemwall foundation edge so that they line up directly under the floor joists.

-

My new job has kept me away for the last few weeks so that getting anything done on the plugins has been a real challenge. Even so I've been giving some thought to stepped footings/foundations and would like some input from the designers and architects out there on what is common practice and what they would like to see available for this sort of feature within the plugin.

View mode here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

Note that I messed up on this model the exterior cripple/pony walls should have only had one top plate so that the combined top plate from the shallow sections and the single top plate would have created the typical double top plate.

Advertisement