3D Truss Models

-

The asymmetric roof addition beat me up pretty hard for about three days, but in the end I won out. Now I need to look at the hip roof and how best to deal with multi pitches...

With the hip roof we are now talking about four different possible top plate heights with four different possible pitches, birdsmouth cuts, and rafter depths.

If one is to assume that the fascia boards all line up (gutters), then the top plates heights are actually driven by the roof overhang and the pitch of each roof plane. Only one roof plane (Plane A) will actually have its plate height set (the zero or base height of the roof), the other roof planes' top plate heights will be automatically calculated.

I suppose there is always the possibility where the fascia don't line up but I think this is more the exception than the rule, correct me if I am wrong.

As I've given this some more thought it occurred to me that typically the designer will set the roof pitches from the outset. Then, in order to get the fascia to line up, he/she can either adjust the overhang or the top plate height (assume that the birdsmouth cut is set to some value). So depending on the situation the user may want the plugin to calculate either the overhang (same top plate height) or the top plate height (same overhang). I will need to give this some more thought.

If the user keys in a numeric value for the overhang (roof planes B, C or D) then the edit menu can automatically set the delta height (top plate heights) for each respective roof plane to "AUTO". Likewise if a value is keyed in for the delta height the HTML form can set the respective overhang(s) to "AUTO".

-

I don't normally post on the boards regarding price changes in the plugins however I thought it might be worth noting that I have decreased the renewal price on the Truss plugin to $10.00. The idea being that once you have paid your initial license fee ongoing renewals are mostly a token payment.

-

Continuing on with regards to multi pitch hip roofs we need to be very clear about what point on the roof lines up when we talk about lining up the fascia. Do we mean the sub-fascia, rafter tail or the fascia?

Since I currently don’t have the fascia and soffit added yet I can probably ignore these for now and state that the top of the fascia board must line up with other fascia boards on other roof planes.

-

That make sense but in cutting rafters or fabricating trusses, isn't the only thing they can really do is line up the top of the rafter tails? Actually if there are tails, the truss manufacturer will leave it to the carpenter.

-

@pbacot said:

That make sense but in cutting rafters or fabricating trusses, isn't the only thing they can really do is line up the top of the rafter tails? Actually if there are tails, the truss manufacturer will leave it to the carpenter.

In the field I think its typical to provide rafter tails that are too long so that they can be trimmed all at once (chalk line) to ensure that they all line up.

-

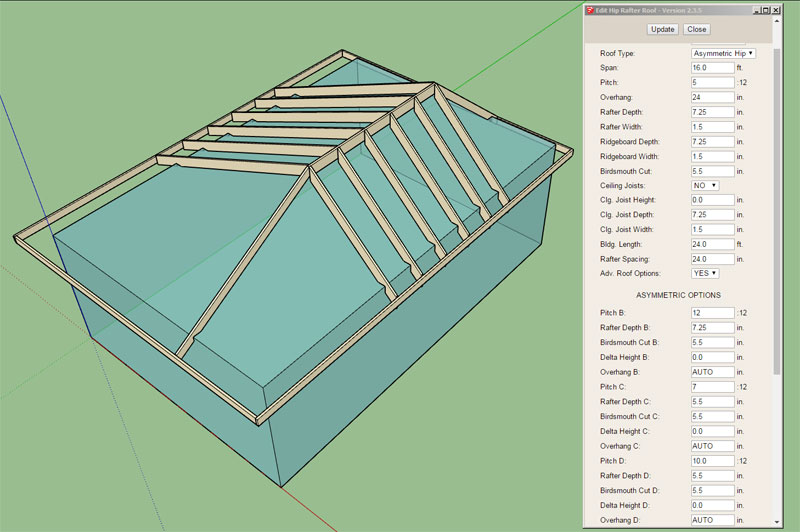

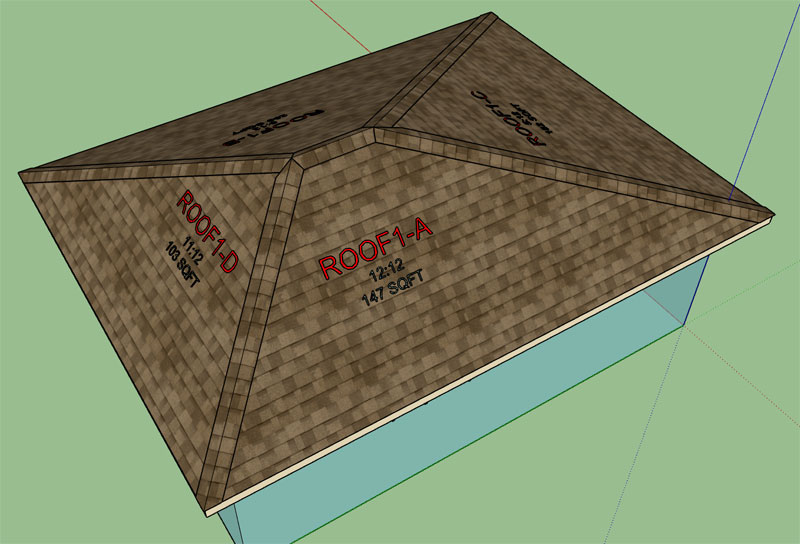

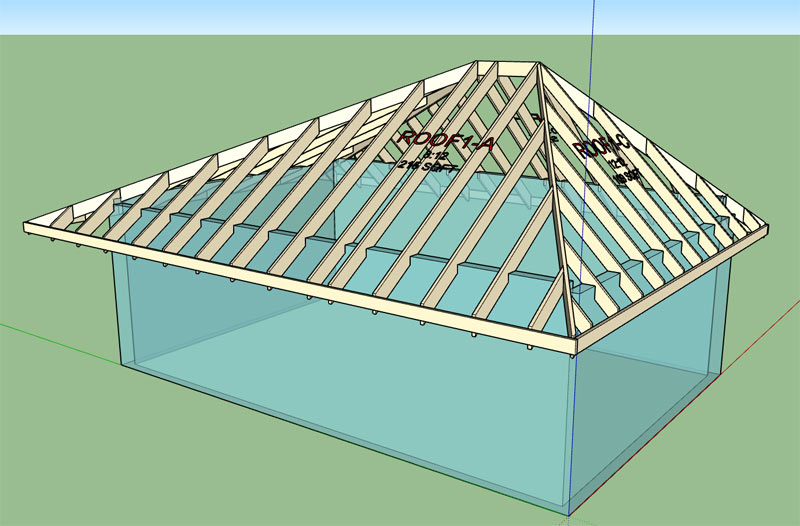

I've got the asymmetric options added to the edit menu and the common rafters and fascia are calculating correctly:

Note that all four pitches are different values, however the fascia lines up all the way around the roof as it should (in this case I have the overhangs auto calculating).

Next I will work on the hip rafters and jack rafters. As we can see in this example, all symmetry is broken, each hip rafter will be unique (x4) as well as each set of jack rafters (x8). Luckily we can program this sort of thing, drawing this type of roof manually would be a real headache.

-

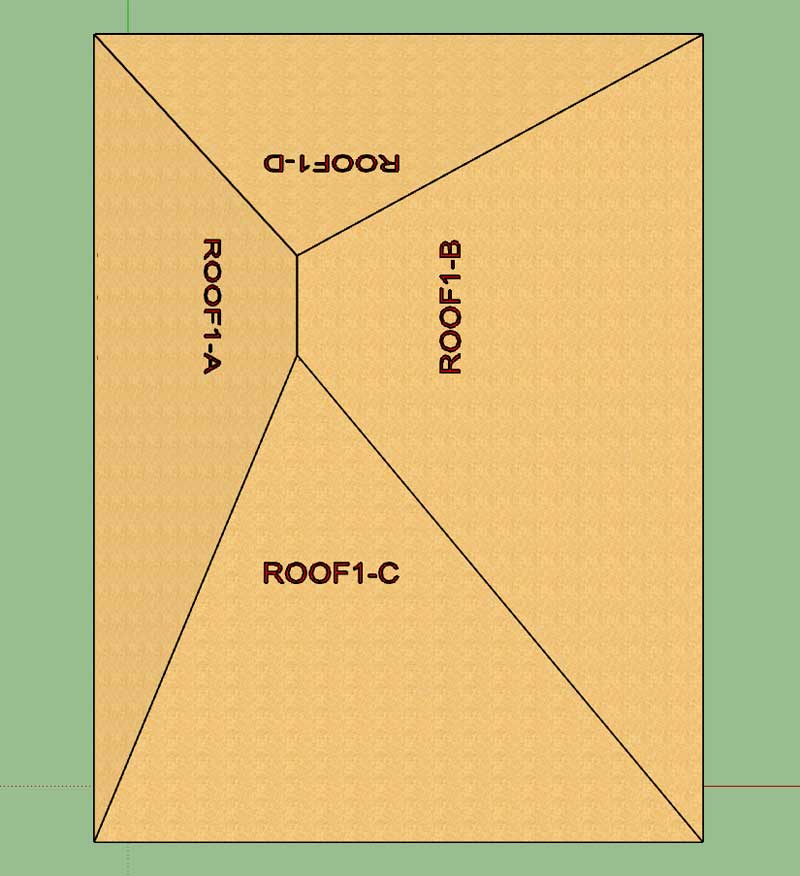

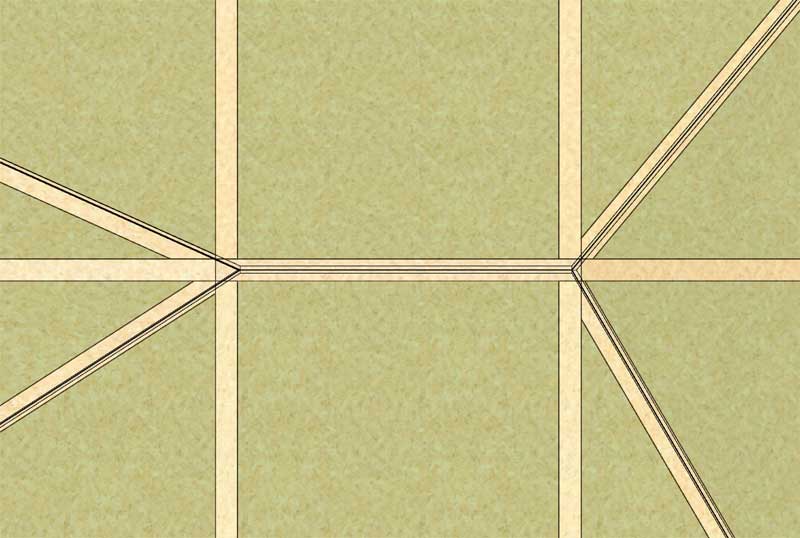

First look at the sheathing and labels for an asymmetric hip roof:

-

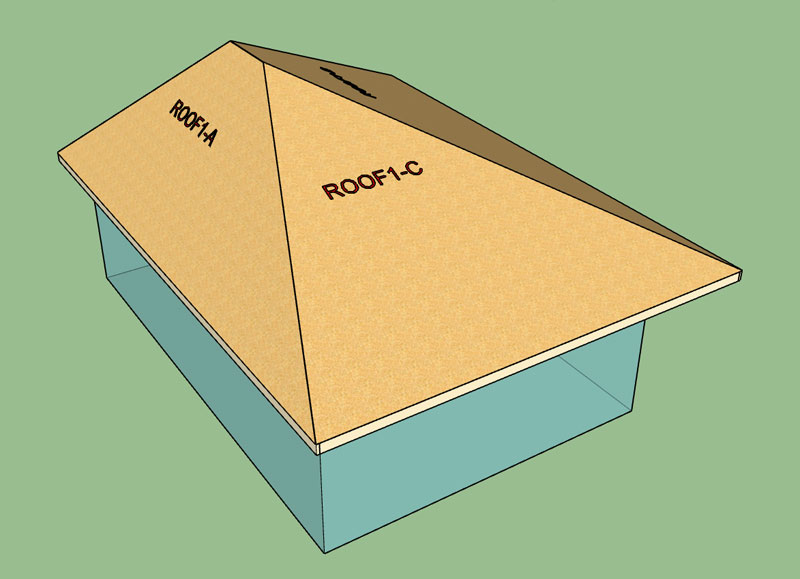

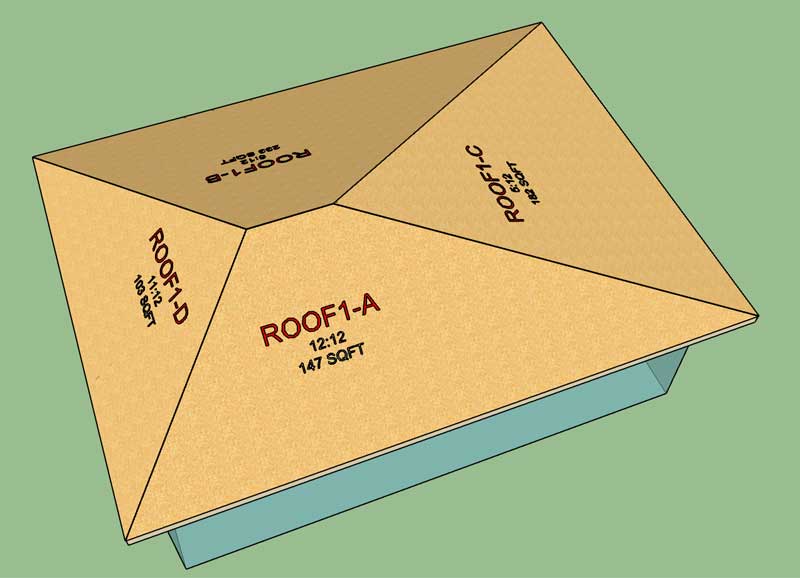

Pitch and SQFT callouts/labels are now working:

-

Hip and Ridge Cap is now working:

This chunk of code is just for the ridge cap geometry:

@Phi1_3 = atan(sin(@Phiplane13) * tan(@Phi) * cos(@Phihip13)) @Phi3_1 = atan(cos(@Phiplane13) * tan(@Phi3) * cos(@Phihip13)) @Phialpha1_3 = acos(cos(@Phihip13) * sin(@Phiplane13)) @Phialpha3_1 = acos(cos(@Phihip13) * cos(@Phiplane13)) @Psi1_3 = asin(0.70710678118 * sqrt(1.0 - cos(@Phi)*cos(@Phi3))) @Phi2_3 = atan(sin(@Phiplane23) * tan(@Phi2) * cos(@Phihip23)) @Phi3_2 = atan(cos(@Phiplane23) * tan(@Phi3) * cos(@Phihip23)) @Phialpha2_3 = acos(cos(@Phihip23) * sin(@Phiplane23)) @Phialpha3_2 = acos(cos(@Phihip23) * cos(@Phiplane23)) @Psi2_3 = asin(0.70710678118 * sqrt(1.0 - cos(@Phi2)*cos(@Phi3))) @Phi1_4 = atan(sin(@Phiplane14) * tan(@Phi) * cos(@Phihip14)) @Phi4_1 = atan(cos(@Phiplane14) * tan(@Phi4) * cos(@Phihip14)) @Phialpha1_4 = acos(cos(@Phihip14) * sin(@Phiplane14)) @Phialpha4_1 = acos(cos(@Phihip14) * cos(@Phiplane14)) @Psi1_4 = asin(0.70710678118 * sqrt(1.0 - cos(@Phi)*cos(@Phi4))) @Phi2_4 = atan(sin(@Phiplane24) * tan(@Phi2) * cos(@Phihip24)) @Phi4_2 = atan(cos(@Phiplane24) * tan(@Phi4) * cos(@Phihip24)) @Phialpha2_4 = acos(cos(@Phihip24) * sin(@Phiplane24)) @Phialpha4_2 = acos(cos(@Phihip24) * cos(@Phiplane24)) @Psi2_4 = asin(0.70710678118 * sqrt(1.0 - cos(@Phi2)*cos(@Phi4))) @Ridgex = (cos(@Phi)*@HRthk*tan((@Phi + @Phi2)*0.5)) - sin(@Phi) * @HRthk @Ridgey = (sin(@Phi)*@HRthk*tan((@Phi + @Phi2)*0.5)) + cos(@Phi) * @HRthk if @Sheathing_option == "YES" if @Roofbatten == "YES" if @Cboption == "YES" thtot = @Cbheight + @Battenheight + @Sheathing_thickness + @Roofcladding_thickness else thtot = @Battenheight + @Sheathing_thickness + @Roofcladding_thickness end else thtot = @Sheathing_thickness + @Roofcladding_thickness end else if @Roofbatten == "YES" if @Cboption == "YES" thtot = @Cbheight + @Battenheight + @Roofcladding_thickness else thtot = @Battenheight + @Roofcladding_thickness end else thtot = @Roofcladding_thickness end end # Extension at Peak @Wa3 = PI - (@Phialpha3_1 + @Phialpha3_2) @Beta23 = atan(sin(@Wa3)/(tan(@Psi1_3)/(tan(@Psi2_3)) + cos(@Wa3))) @Beta13 = @Wa3 - @Beta23 ext13 = (thtot * tan(@Psi1_3))/(tan(@Beta13)) ext23 = (thtot * tan(@Psi2_3))/(tan(@Beta23)) @Wa4 = PI - (@Phialpha4_1 + @Phialpha4_2) @Beta24 = atan(sin(@Wa4)/(tan(@Psi1_4)/(tan(@Psi2_4)) + cos(@Wa4))) @Beta14 = @Wa4 - @Beta24 ext14 = (thtot * tan(@Psi1_4))/(tan(@Beta14)) ext24 = (thtot * tan(@Psi2_4))/(tan(@Beta24)) # Ridge Length and Extensions ridgedx = (cos(@Phi)*thtot*tan((@Phi + @Phi2)*0.5)) ridgedy = (sin(@Phi)*thtot*tan((@Phi + @Phi2)*0.5)) length_sq = thtot**2 + ridgedx**2 + ridgedy**2 rext3 = sqrt(ext13**2 + (thtot/(cos(@Psi1_3)))**2 - length_sq) rext4 = sqrt(ext14**2 + (thtot/(cos(@Psi1_4)))**2 - length_sq) phicheck3 = atan(ext13*cos(@Psi1_3)/thtot) + PI - @Phihip13 phicheck4 = atan(ext14*cos(@Psi1_4)/thtot) + PI - @Phihip14 if phicheck3 > PI rext3 = -1.0 * rext3 end if phicheck4 > PI rext4 = -1.0 * rext4 end @Ridgecaplength = @Arraylength - @Hipf - @Hipb + rext3 + rext4 -

WOW.

I hope you never see a roof like this, but kudos for handling the situations where we may have a couple different pitches anyway.

-

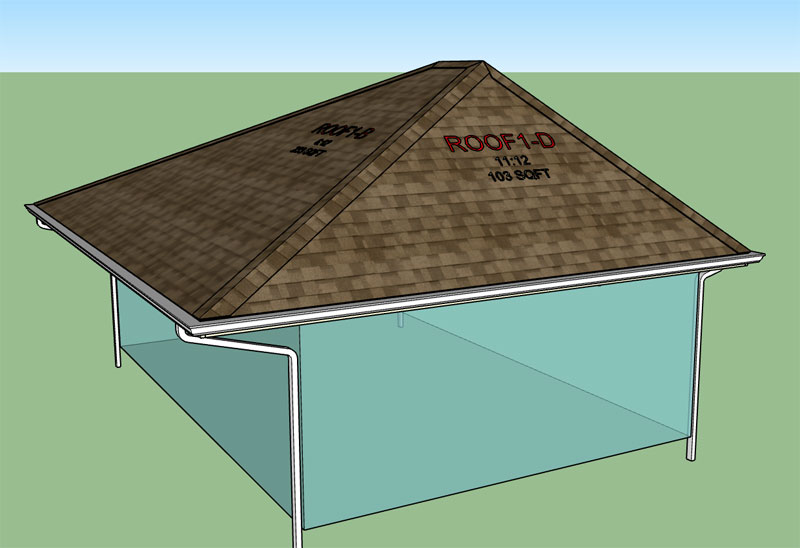

Gutters and Downspouts are now functional for the Asymmetric Hip Rafter Roof:

Even with the different overhangs and top plate heights the gutter height (fascia) is the same height all the way around. However the downspouts on opposite sides of the roof are customized per the overhang on each respective side.

Tomorrow I will jump back into the hip and jack rafters and see if we can wrap this one up.

The good news is that the required code for the asymmetric hip and jacks already exists. I will be borrowing from the roof return module where I handled dissimilar pitches. The bad news is that after a cursory review of this block of code I have absolutely no idea how it actually works anymore (I haven't looked at it in about 2 years). It's just a matter of reverse engineering my own code for about an hour and it will all come back to me.

-

I'm actually still working on the hip rafters. The complexity of a multi-pitch roof took another unexpected turn with the realization that when roof planes A and B are different pitches it causes an offset in the rafters at the peak which requires some additional logic to account for this fact with the placement of the hip rafters and their geometry.

I'm also still a bit conflicted on how to best handle the birdsmouth cut of the hip rafters when they walls have different top plate heights. In some cases the hip rafter misses the corner entirely and is askew on one of the walls, this is the simple case. In other cases the hip rafter technically rests at the "corner" but since there are two different wall heights possible it is not clear how the birdsmouth cut should be constructed exactly. I'm assuming that the higher plate height will govern.

Does anyone have any photos or details of actual construction where a hip rafter bisects a corner where the top plate heights vary?

-

Got me looking for examples. I've created (or passed on) far more problems like this for others, than I ever had to deal with in the field. You might look at this guys webpage. https://deskgram.net/explore/tags/bastardhip

-

Note how this hip rafter sits askew, only on one wall:

-

Yes. I once did a little roof framing, using old school framing square methods from a book. Sometimes I just had to work it out in the field.

-

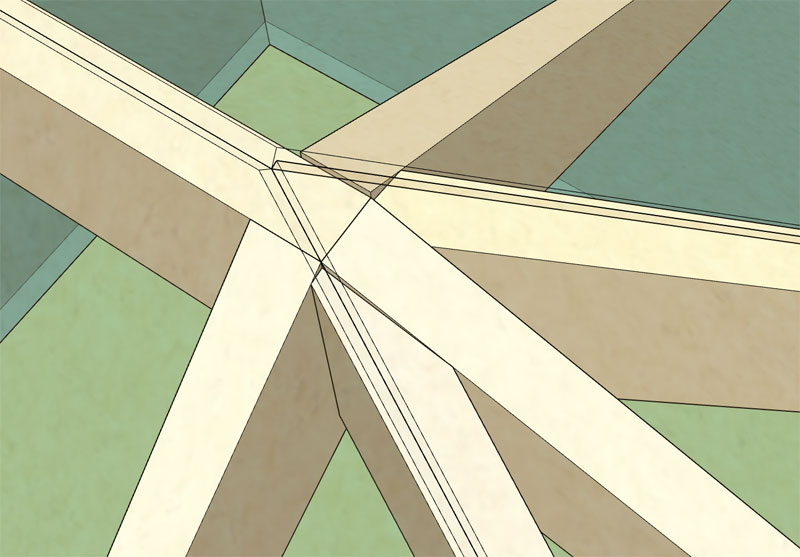

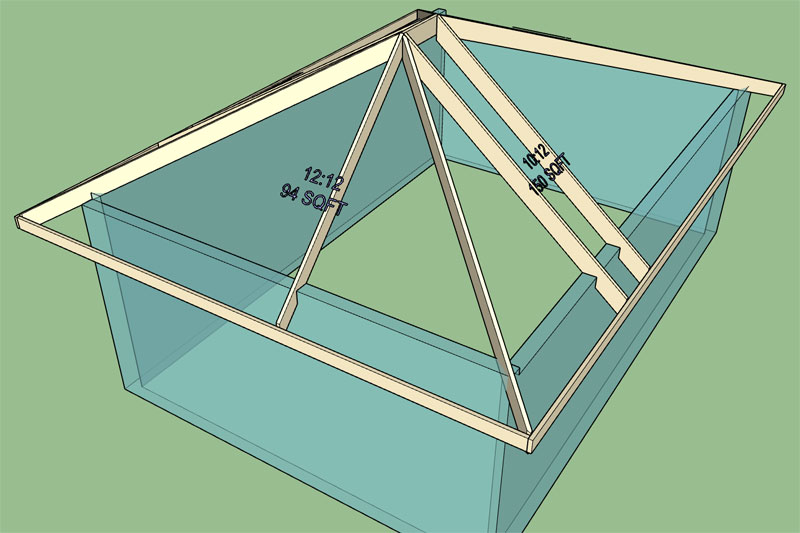

When the hip roof is asymmetric across the ridge you end up with a situation like what is shown below:

The common rafter in the upper right is a 7:12 pitch and the common rafter in the lower left is a 10:12 pitch. Normally with a symmetric hip or gable roof the common rafters would be flush with the top of the ridge board.

However in the asymmetric case the steeper pitched side is flush and the lesser pitched side overshoots the ridge board just slightly as shown. This additional asymmetry causes further complications in the calculations of the hip rafter that is adjacent to the overshooting common.

Also note that the seams in the sheathing (edges of the roof planes) do not center up on the ridge board or hip rafters. This is not a flaw or an error it is just the way the asymmetric roof goes together.

It appears that I have the hips correctly calculating now (after nearly two days of intense debugging and about 10 sheets of engineering pad) however tomorrow I will continue with further testing, to see if I can break anything, and then begin attacking the jack rafters.

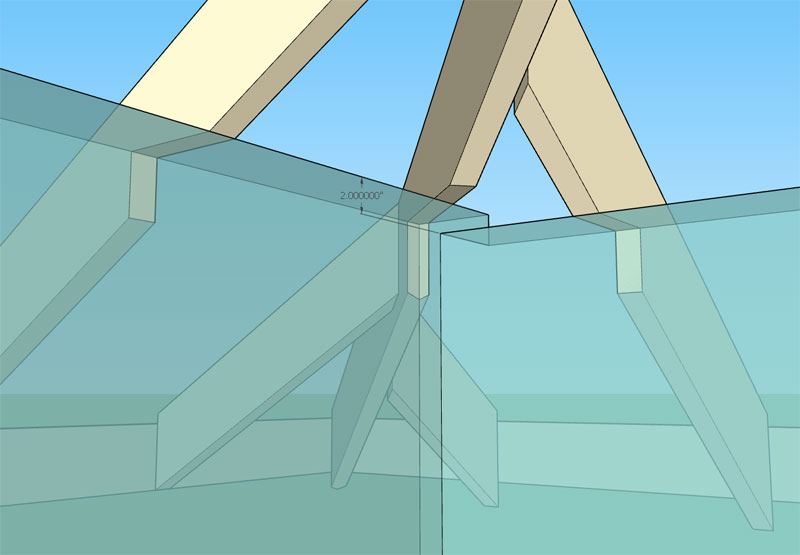

A further look at the bird mouth cut question in shown in the example below:

So in reality I am still missing the birds mouth cut for the hip rafters and the implementation of the soffit cut for trimming the tails of the hip rafters. Always too much to do and never enough time to get it all done.

I'm really hoping that the jack rafter piece is a lot less trouble than the hip rafters, I would really like to get this roof type wrapped up by the end of the weekend.

-

Since each hip rafter is potentially unique each one requires the following calculations (for those that are interested):

@Returnext = @HipendX + @Overhang3_num @Returnext2 = (@Pitch3/@Pitch) * @Returnext @Returnexthip = sqrt(@Returnext * @Returnext + @Returnext2 * @Returnext2) @Zeta = acos(@Returnext/@Returnexthip) @Tcy4mod = 0 - @Fascia_width * (tan(@Phi) - tan(@Phi3)) @Returnext2mod = @Tcy4mod/(tan(@Phi)) @Zeta_a = atan((tan(@Zeta))/(cos(@Phihip13))) @Zeta_b = atan(tan(@Zeta)*cos(@Phihip13)) @Iota = atan(sin(@Zeta)*tan(@Phihip13)) @Kappa = atan(cos(@Zeta)*tan(@Phihip13)) @Term1 = (cos(@Zeta_a))/(cos(@Iota)) + ((sin(@Zeta_b))/(cos(@Kappa))) * ((tan(@Phi) - tan(@Iota))/(tan(@Phi3) - tan(@Kappa))) @Abar = @Ply/@Term1 @Hipoffsetx = (@Returnexthip - @Ply) * sin(@Zeta) @Bbar = @Abar * ((tan(@Phi) - tan(@Iota))/(tan(@Phi3) - tan(@Kappa))) @Ebar = @Returnext - ((@Returnext2 + @Returnext2mod - @Abar)/(tan(@Zeta))) @Fbar = @Returnext2 + @Returnext2mod - (tan(@Zeta))*(@Returnext - @Bbar) if @Phi2 > @Phi @Zbar = @Ry4 - @Ry4r @Xbar = @Zbar/(tan(@Phi)) @Bbarmod = ((@Abar+@Xbar) * (tan(@Phi) - tan(@Iota)) - @Zbar) / (tan(@Phi3) - tan(@Kappa)) else @Zbar = 0 @Xbar = 0 @Bbarmod = @Bbar end @Exthip13 = ((@Xbar+@Abar)*cos(@Phihip13)/tan(@Zeta))/(cos(@Phialpha1_3)) - @Zbar/(tan(@Phihip13))Term1 of the Abar equation is really interesting. If I took the time I could probably condense down some of the variables and reduce the amount of algebra but then in the future it would be harder for me to follow, so it is best left as verbose as possible for myself and future generations.

The terms Abar, Bbar, EBar and Fbar specify the compound bevel cuts at the peak and eave of the hip rafter.

-

Actually I stand corrected. The sheathing does center up on the ridge board provided that you do vertically offset the opposing common rafters as shown in the previous images. A top down view shows the result:

If you don't vertically offset the commons and the pitch on plane A and B differ then the ridge board will not center up on the sheathing. For now I have it centering and a vertical offset, for future work I may provide an option to toggle between these two possible configurations.

Here is a view of the other side of the roof, note the different top plate heights and where the hip rafters land on them and the corners:

Better yet, go ahead and download my test model that was most recently generated by the new asymmetric module:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

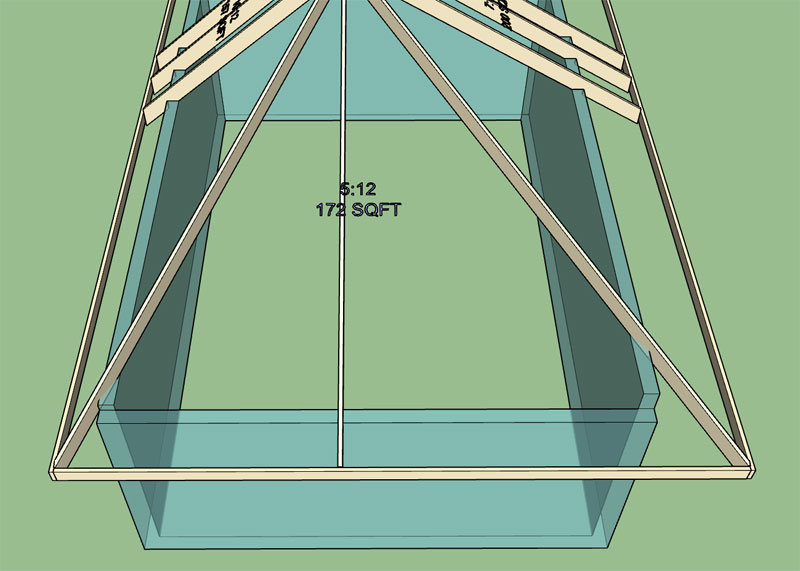

First look at the jack rafters:

Next I will look at the birds mouth cut of the hip rafters and the soffit cut for both hip and jack rafters, then a bit more testing to see if anything can be broken when the degenerate case (symmetric roof) is calculated.

These is also the case where you might end up with a negative overhang (which doesn't make sense). I should probably include some logic to try and detect this condition and alert the user that the roof configuration is not physically possible.

-

The birds mouth cut algorithm (and code) is now functional however I can't say I'm completely satisfied with it yet.

For example take a look at this scenario:

You have a 8:12 and 7:12 meeting almost at the corner of the building (skew is minimal) however the plate height is 2" higher on the 7:12 side and my algorithm cuts the birds mouth per the highest plate height at the corner.

In this particular case it would seem to make more sense to cut the birds mouth at the lower plate height otherwise not enough meat is left in the hip rafter. This algorithm may need further refinement to really make it meaningful and useful to the designer.

The other option of course is to simply not cut the birds mouth in the hips rafters and leave it to the user to determine what or how they want to handle the intersection at this critical junction.

The soffit cut in the case of a hip roof is actually quite simple (surprisingly). Since the fascia lines up all the way around the roof the soffit cut will also be the same height for all jacks, commons and hip rafters.

Advertisement