Volume Models get destroyed by some volume functions

-

Hello guys,

I am using Sketchup on a regular basis to quickly model parts for my 3D Printer.

So far so good. Once I have finished my design I make it a "Volume-model" export it as .stl and print it.Unfortunately for some models merging or subtracting even simple geometric shapes destroy their manifoldness, so the model is no volumentric-model/volumemodel?! anymore...

I am getting so frustrated by this random behavior, I could sometimes slam my fist through my laptop.

Sometimes I will sit here, design something for several hours but one final subtration will not work, whereas the subtraction of 9 similar cylinders worked perfectly finde before...

So today is such a day again:

I have modeled a simple clamp to print it out and test it`s rigidity.

It is a clamp block supposed to connect 2 15mm Carbon fiber rods.

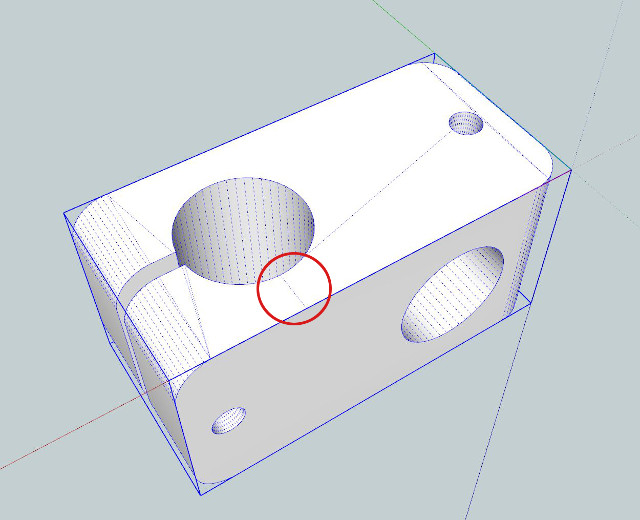

here is a picture of it:

now in order for the clamp to work I need to cut out a 2mm thick slice -> so that the hole can be compressed slightly and hold the rod firmly.

Therefor I create a simple rectangle made in volumetric model, moved it to the desired position and start subtrating it from the clamp:

like so:

What happens now is, it loses part of its shell.

now I CAN close the hole, but it will never be a "volumetric-model" again, no matter what I try!

I spent an hour trying to make it a volumetric model again.

I use solid-inspector -> it always shows me some triangles marked red:

So if I delete that one whole face will disappear.

I draw a new line to make the face appear again, object is not manifold/Volumetric anymore.I am close to insanity...

please help me out here or give the clue I need.

Something like this happens quite often to me,

usually on every other model.

It is a real PITA.maybe I am just stupid and doing something wrong,

but in my opinion those Volume-body-functions should just work when every object i manifold...anyways, hope somebody has already had similar experiences and can help me,

would really appreciate a hint here.BR,

Alex -

One simple fix that usually works for this sort of problem is to scale up by a factor of 10 or 100 to work on the model and scale down again when finished.

-

Note, scaling up by 10 or 100, you will find it hard to scale back to the original size. If you scale up by 25%, "OrignalPartSize" x 1.25 then you can downscale by 80%, "NewPartSize" x 0.80 and you will be at the same size as the beginning size.

I believe this is the only whole number scale factor that upscaling and downscaling will arrive at the original size without getting into decimal scaling.

I have modified a ruby script to do this, upscale by 1.25%, downscale by 80%. If 1.25% is not large enough, I do the upscale a couple of times, just remembering the total times upscaling, then downscale the same number of times.

I find this script a real help in using 3d text, I input the text, upscale or downscale until I get the size I wish.

Ken

-

Umm Ken, take a 1mx1mx1m cube, scale by 10 it becomes a 10mx10mx10m cube, scale by 0.1 it becomes a 1mx1mx1m cube again. Or am I doing something wrong with my mathematics.

-

@box said:

Umm Ken, take a 1mx1mx1m cube, scale by 10 it becomes a 10mx10mx10m cube, scale by 0.1 it becomes a 1mx1mx1m cube again. Or am I doing something wrong with my mathematics.

Nope, your right. My bad, I was doing %, so I was stuck between, 100% and 200%, as I was just trying to make a small adjustment. However, it you go to 10 times, then .1 will get you back to the original.

Caught with my math pants down.

Thanks for clarification and correction.

Ken

-

No worries Ken, when you start throwing feet, inches and fractions into the mix as well it all gets a bit confusing.

The other thing with scaling is you can always scale a component instance and edit that and delete after, which saves you the problem of scaling down again.

-

Dave mention that method. I find this method very useful.

Ken

-

Ken, I'm glad you find that method useful.

Another thing you can do of course is scale up and down with the Tape Measure tool instead of the Scale tool. I still prefer scaling the copy of the component and discarding it when I'm finished with it.

-

Booleans were a great addition to Sketchup but, as Alex wrote, the operations fail often once the model gets slightly more complex. Especially now when 3d printing gets more popular every day, some new attention to booleans would be very welcome or people will have to look elsewhere.

My 2 cents (easy for me to ask - I have no knowledge how big a task this list would be):

- refine the algorithms so that more complex models would still work.

- add some new functions that speed up the work like: make solid (closed volume enclosed by several planes - even curved planes), slice by plane (even curved planes), round selected edges (we have a great plugin by Fredo for that but with more complex boolean models the plugin won't always work - would be nice if this could be possible somehow)

- remove the necessity for having to scale the model for booleans to work correctly

- don't rename the boolean outcome to 'union etc' but leave the original name, maybe only add a suffix like a&b if the outcome are different parts.

greetings, Max

-

@alex84 said:

...I am close to insanity...

...

...Just wanted to add...

A trick if the booleans start to fail is to use 'intersect with selected' instead of boolean-subtract. Copy the resulting intersection lines into the base-solid and manually start deleting / adding faces.

If the original shape is already quite complex, copy the cutter and only the faces that would be affected by the boolean subtraction above the model and do the intersection there. It's sometimes much faster. -

Hello guys,

thanks a lot! for the answers

really appreciate it.I have been looking for my thread under the "sketchup-bugs" section

and since I could not find it there I figured, it must have not yet been reviewed.Now, after little over a week I decided to look into my profile where it says "your posts" and was pleasantly surprised to find so many answers.

I tried to scale by factor of 2 - did not work.

I tried to scale by factor of 10 - did not work, also factor of 100 did also not work.So I am not sure what else to do.

I am uploading the file as an attachment to this post, so maybe any of you could give it a try and see if it works for you.

All I want to do is subtract the rectangle from the clamp in such a way, that the left side of the clamp is open and can contract, when a screw is inserted.

best regards,

Alex -

Hi, Alex:

I downloaded your skp to try it out.

First off: The skp opened with the model upside down. The template you are using has no feature to indicate directionality except the "solidity" of the axes colors. I don't know if Sketchup cares which way is up, but I like to work with ordinary frames of reference.

I went to check which template you were using--metric, product design and woodworking, I think. I tried to retain it, and return to the model, but the program froze up, and I had to shut down and reboot, so I didn't continue.

Dave Richards' method of up-scaled component instance editing would be the way to go. Probably scale by 100. 25mm would be 2500mm--but it's still 25 somethings.I may come back to this later, but I am out of time right now.

-

One thing about using my method of scaling up a copy of a component is that Solid Tools converts components it modifies to groups so the original doesn't get modified. This is something I've been asking them to change but apparently I'm the only one who wants components to remain as components with Solid Tools. For that reason, I only use the Solid Tools when they would result in less work than using Intersect. I take in to consideration the whole process not just the intersecting but potential scaling, re-converting to a component, changing axes and correcting the other instances of the original component.

If all you're trying to do is cut a slot in your clamp, I would just make the clamp a component (I wouldn't have made it a group in the first place), copy it and your "cutter", scale up the copies by a factor of 100 or 1000 and use Intersect Faces. Then, when finished, close the clamp component to get out of edit mode and delete the giant copy.

-

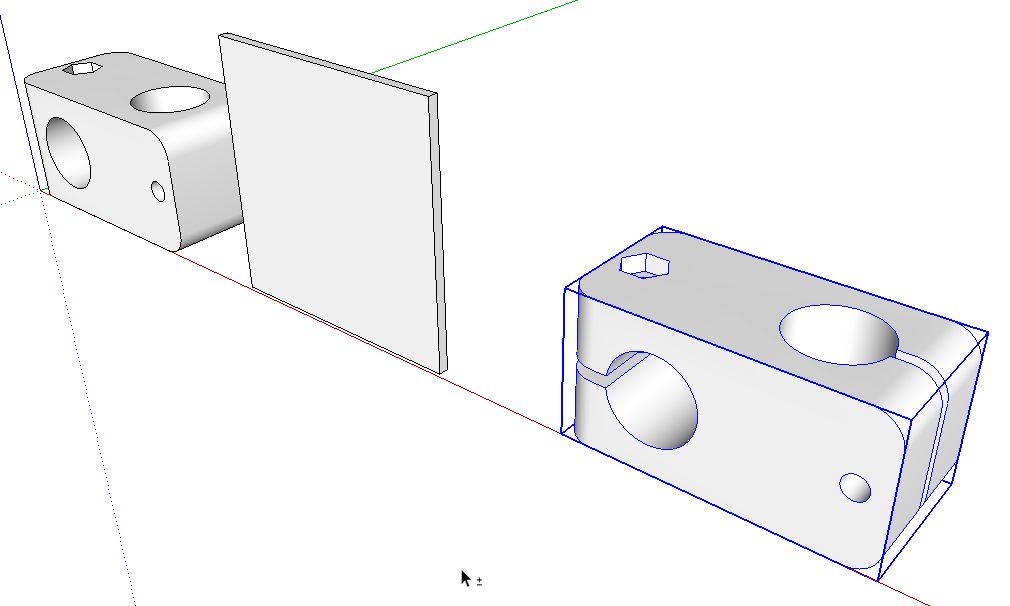

Try the attached file - used R2014, saved in R2008.

Steps used:

- deleted all the guides (not sure if it was necessary),

- did the boolean,

- your 'pestering triangle' appears.

- I didn't like all the lines coming to 1 point on top so deleted some and I added a new line (see image)

- by doing so, cap was filled automatically but still no solid

- solid inspector reveals problem with same face - deleted that one and turns out to be another one there -> now Solid

edit: tried again with same solid result in R2014:

- did the boolean

- filled the gap, no solid

- solid inspector reveals problem with 2 triangles

- deleted those 2 triangles, no gap appears - were double - no solid

- solid inspector reveals 1 tiny triangle still a problem

- deleted triangle, reveals another, continue deleting (3 times) until gap appears, undo 1 step

-> solid

-

I had a look at your model and found some precision related errors. I redrew it from scratch. I didn't have any problems with the weird diagonals and disappearing faces. I'm thinking that most of the issues you are having are self-induced. By working at a larger scale (easy when you're working in metric units, too) and with higher precision, you're more likely to get the model you want.

Although you didn't show it, I took the liberty of adding a slot in the opposite end of the clamps so that end would work the same way.

FWIW, since both ends of the clamp are identical with one end just rotated 90 degrees, I only drew half of it. Then I copied the half, rotated it as needed and moved it up to the first half. Deleting the seam line made it a single piece.

-

Rounding edges last might make things easier. With roundcorners plugin, it just means a couple more clicks, (due to the split edges in your model)

-

Peter, that's a good suggestion. Even doing the round overs with native tools would be trivial.

-

Hi, Dave:

I think you meant to address Peter rather than me above. -

@mitcorb said:

Hi, Dave:

I think you meant to address Peter rather than me above.Whatchoo talkin' 'bout, Willis?

Thanks. I fixed it.

-

thank you a lot @ all who have tried ans especially

Dave R and kaas!Upon another close inspection I found out that one edge consisted of only 10 faces while all 3 other "rounded-edges" had 12 rounded faces...strange.

Plus I could clearly see those "precision related errors" Dave was speaking about,

I must clearly have messed something up big time unintentionally by being a very few mm off without noticing it!The red-axis for example does not run parallel to the objects outer edge.

maybe it is so slightly off, that it is "ok" for the object as it is, but once solid-actions are performed it just looses it.Anyway. Am happy to have a working clamp now and will pay even more attention to those little details in the future.

thanks again to everybody who wrote in this thread.

best regards,

Alex

Advertisement