Sketchup needs to be BIM

-

@utiler said:

That sounds neat, Nick... would love to see the process pics...!

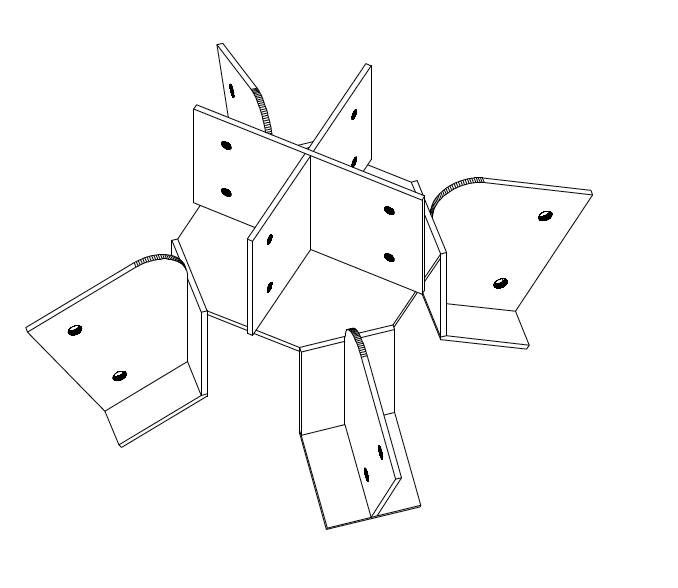

The piece is a center steel knife plate with 8 plates. It is 54" in diameter. In the first video, that google released on my process, there is a small segment showing the model of this element.

No shop drawings were prepared other than the SU model.

Here it is freshly installed.

-

-

@unknownuser said:

@unknownuser said:

Here it is freshly installed.

are those 6x6s ?!

They are 12x12's - 200 psf snow load. The structure is 18 feet in diameter - center point to center of segment of course

-

The element above is the top of a 3 story stair tower. Here it is finished (unfortunately the photographer couldn't easily capture the element, but it gives you a better idea of scale:

-

nice man

-

This reminds me of a connector I put together for a project a few years back for ridge and valley timbers over a log post. Didn't have the luxury of a plasma cutter though, so it was hand fabricated. It was pretty much mostly buried anyway but it made for an interesting structure. These kinds of details are fun to design.

Advertisement