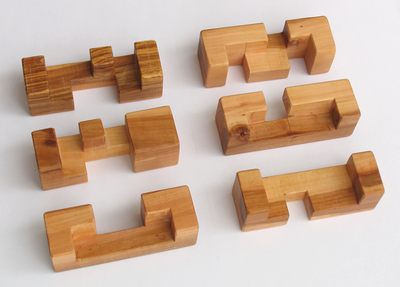

Chidori furniture joint

-

Impossible to make it eyes closed!

Carreful there are variations as shown here

It's not mine!

or

etc...

[flash=420,315:1nd228mp]http://www.youtube.com/v/dTGO_NR6YiA[/flash:1nd228mp]

-

And I am very curious to know how

they build in wood because you must make some very little decrease/ decrease measures against a computer 3D model!

(for easy sliding)

If you don't know the solution i don't see how that is possible

-

@woodarc said:Is anybody familiar with this system. I'm looking for details of the joints. The system apparently consists of 12 sticks with different junction details which connect without the aid of glues, nails or screws. I've checked out Amazon but with no joy. Any leads would be greatly appreciated. Many thanks in advance.

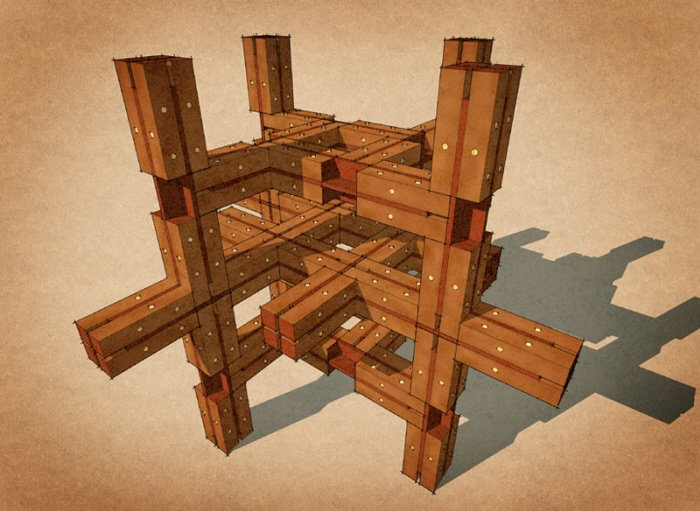

Reminds me of a system that I came up with in architecture school.

-

@unknownuser said:

And I am very curious to know how

they build in wood because you must make some very little decrease/ decrease measures against a computer 3D model!

(for easy sliding)

If you don't know the solution i don't see how that is possible

You can hardly make it exactly right in the Model because the 'cutting' has so many variables...

You make some 'clamped on jigs' on your table-saw or router-table [these depend what you are using to make the cuts!] for the max/min extents of the various cuts. You make some test cuts and see how they fit together. The jigs can be 'fine tuned' by adding thin paper shims between its parts to reduce the amount cut off [or by removing them to increase the amount that is cut off] ... until the test cuts fit snuggly together - if it's a dry fit you want a tighter fit that if it were to be glued as you have to leave space for the glue! Of course if you had one of the clever [but expensive] Incra jigs [ http://www.incrementaltools.com/ ] you could input 1000th of an inch adjustments until your cuts were perfect... -

Roger - that looks similar to a coffee-table I made over 35 years ago - remodeled in Sketchup...

-

-

@dave r said:

I'd cut the joints with this:

A simple fixture as TIG mentions would make it simple to create accurate joints.

I would too if I had one.

-

I know where you can get one.

-

In the case of the Puzzle headache...

I am agree with all these tools can make any precision cuts but that can't say what "sides" must be increase or decrease!

Without the entiere solution's path known!

Else the gliding will be blocked at some place!

It's not only the "nicks" but sometimes an entiere side face must be cut!

And without the solution you can't build it!

-

Hello, Woodarc. I know how to do this joint (= I have worked out how to do it) the way that Japanese design house does it. Since I am brand-new to this forum, and don't know how to post photos, best you go to this link where I tell the whole story (for one sample joint):

It is a lot easier to make than the replies on this thread suggest - and easiest of all if you have a radial arm saw.

Love this crazy forum. I will be back.

Cheers

Mark

Advertisement