Best practice for drilling multiple holes?

-

One obvious solution would be to give the top-level Component some attribute. If the report script finds the attribute, the script would just skip iterating the sub-components.

Alternatively, sub-components could be named using a special characters (end_plate, for example) which the script could easily check and not count as it builds the report.

-

@jim said:

@gridbeam solutions said:

is there a way to make the component so users can specify the length in feet an inches?

Yes, but it becomes more difficult if there need to be partial units. For example, using the 1.5" base unit, would the DC need to work for a length of 5"? If so, then a fractional-unit component would need to be introduced.

Gridbeam doesn't need partial units. The beam lengths are always multiples of the beam width -- usually, but not always, even multiples.

Thus for 1.5" beam, lengths might be 1.5", 3", 4.5", 6", 4.5 feet, 8 feet, etc. For a beam 2" wide, lengths are always multiples of 2".

Same for metric: If a beam is 40 mm wide, the beam lengths will be multiples of 40 mm -- again, usually even multiples.

-

@jim said:

@gridbeam solutions said:

How do dynamic components work with parts list generators?

Several reporting scripts already exist, and it would be fairly trivial to write a script customized to your Components.

Thanks! I installed Cut List, tested it, and it did exactly what I wanted.

And thanks to the tips you gave Dave R, I now know how to get SketchUp to list only the parts I want counted.

-

There is another option to size the Component - the Scale Tool.

In all, there are 3 possible ways to size the component. 1) Enter a value in an input field, 2) Select a length from a drop-down list, or 3) use the Scale Tool. Unfortunately, the 3 methods are mutually exclusive.

-

hi guys,

i´ve a slightly different question, but it´s about the "holes" too ( i don´t want to make another new useless thread )

( i don´t want to make another new useless thread )

it´actually talking about perforated plates.

i´m newly owner of 1001bit pro plugin, but found it can do just square holes.

when i make them an old fashioned way like here, sketchup collapses many times

do you know why, because my laptop works like a charm?

your valuable tips are very appreciated.

cheers!

-

Make the flat face.

Draw a circle the required size.

Select its face and 'delete'.

Select the circle and Move + Ctrl offsetting the copy the required amount to the side [X/red].

Immediately type 12x [or whatever number is needed to array the circular holes across the face]

Use a fence to Select all of these circles.

Use Move+Ctrl again to array these in the opposite axis [Y/green] the required number of times NNx.

If the original face in not rectangular now manually Erase unwanted circles or parts at edges etc/

PushPull the face to make a 3d perforated panel.

Make it into a Component so its geometry is kept separate and if it'll be used several times you only need to edit one of them...

Use a sensible number of segments for these circular holes, because geometry that's not needed will kill [or at least hamper] Sketchup. You can of course use any shapes holes you like, and also have varying X and Y offsets -

-

hi tig,

thanks for a quick answer and amazing tut.

i didn´t think a large amount of circles can cause any "nausea" to this excellent problem

nevermind, next time i have to be careful with that.

have a nice weekend, and hope like the tiger !

-

hi dave,

thanks for another valuable tip on how to make performated plates.

glad to be here, to learn from you guys !

hope to use 1001bit pro on another occasion.

cheers!

-

If you Move+Ctrl to array-copy a hole across a face then the hole occurs in the copies too...

You'll only need to erase the face of the 'parent' hole that's used to make the various copies in my tut... -

hi guys ,

i ´m often forced to import preworked vector 2D design, logo etc. to sketchup, and i do it via DXF file.

when 2D design contains minimum poits, it become deformed after inport to SU.

but when i fill my design with points,import is fine, curves are smooth, then i like to use WELD plugin,

it´s take an hour to turn separate line segments into a continuous poly-line

is there any other way, how to import vector design into SU in perfect shape with minimum points please?

i´m sure it can be solved, but not without you !

note. i´ve been just tested a few plugins below.

( a new weld plugin and vertex tool didn´t help, WP never beep when done, clean up plugin is a great and fast tool,

but it joints only straight segments (lines) , rounds ones leaves untouched ( arcs ),

recurve 1.5 doesn´t help with a large amount of lines, i works for 50% with a small groups of both types.

thanks in advance for sharing your wisdom

note: the two ways bellow are okey, but they don´t solve plenty of points of final design in SU

-

Open your EPS file in Illustrator and select all.

-

Go to Object>Path>Add Anchor Points. (by default when you click this it adds an anchor point in the middle of every other anchor point you have) The smoother you want your curves the more Anchor Points you will want to add.

-

Then go to Object>Path>Simplify and check the "Straight Lines" box. Bring your "Angle Threshold" down to 0. You can check the preview box and see how it looks.

-

Export as a .dxf/dwg file and insert into SU.

-

Redraw one line so SU will recognize the shape and fill.

-

EPS to WMF

-

WMF import in AutoCAD

-

Save as DWG 2004 version

-

Import to SketchUp

-

-

hi,

**i´d like to announce, that my long-term problem has been solved

with the kind help of "thomthom"** (i mentioned above)

here: http://forums.sketchucation.com/viewtopic.php?t=24593

he truly deserve my admiration and respect for his wisdom.

god bless him!

-

Hi guys,

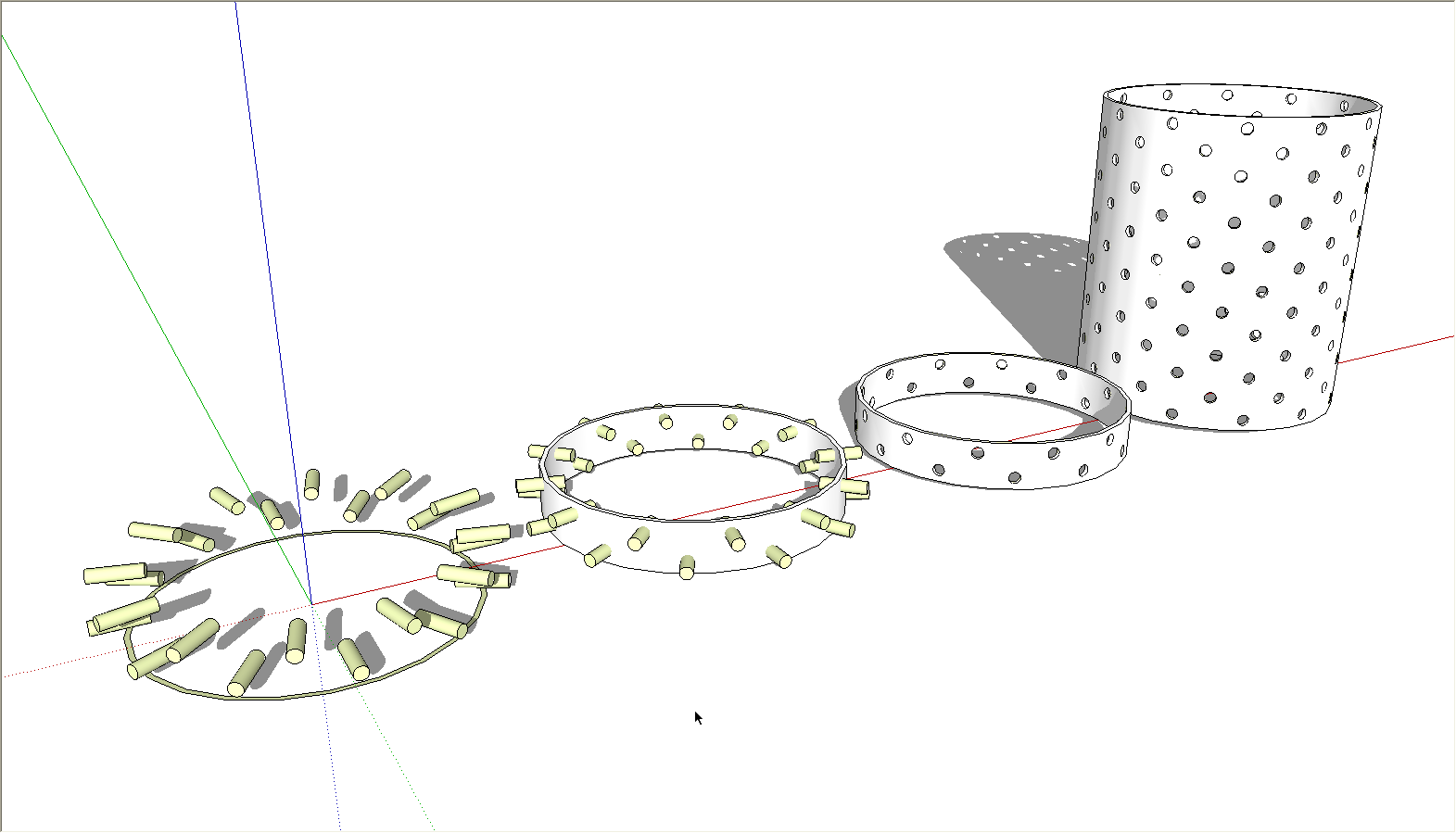

I don't know if I write in a right section, but I need to do multiple holes in a cylinder.

Like this photo. How Can I do that?Thank you in advance.

-

Pilou will be along directly and suggest that you use Shape Bender which you could certainly do but you can also do it manually without problem.

Draw a cylinder for the hole, Rotate/Copy to make a radial array of the holes, copy the array up and rotate halfway between to get the staggered holes.

Draw a cylinder centered on the the array of holes

Intersect the "holes" with the cylinder. Delete the waste.

Copy the section up as many times as needed.

If you have the pro version of SketchUp, you could use Solid Tools to create the holes more quickly.

Advertisement