Trimming outside miters

-

Hi, I'm looking for a way to trim outside miters when running rope molding, as I have to cut and past each piece the corners are giving me a lot of trouble any help is most welcome.

John -

John, how have you drawn the molding? You can use a cutting plane intersected with the molding to cut the miter. I've got an image that shows it. I'll post it shortly.

-

I pasting a rope molding ontop of a extruded crown.

-

Did you draw the rope molding?

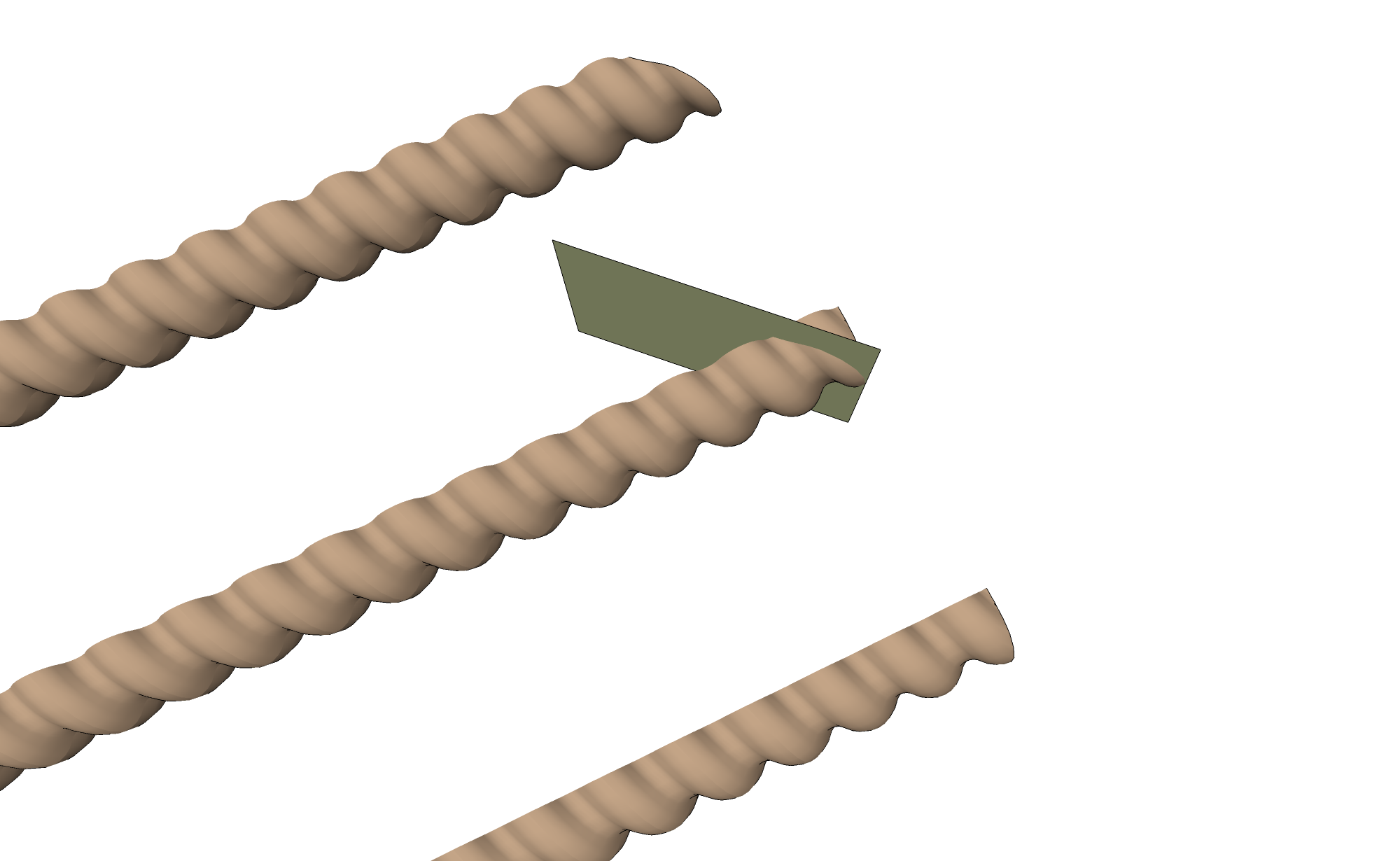

Here's a quickie example of cutting the miter. The same process could be used for any molding.

From the bottom:

Molding, unmitered.

Cutting plane draw at location of miter.

After selecting the cutting plane and the molding, running Intersect with Selection and deleting the waste we have the miter on the end. -

THANK YOU DAVID, it's been driving me crazy for several hours this is going to make my life a lot easier.

John -

Glad to help. Remember, as I said before, this same method can be used for any molding that needs to be mitered.

-

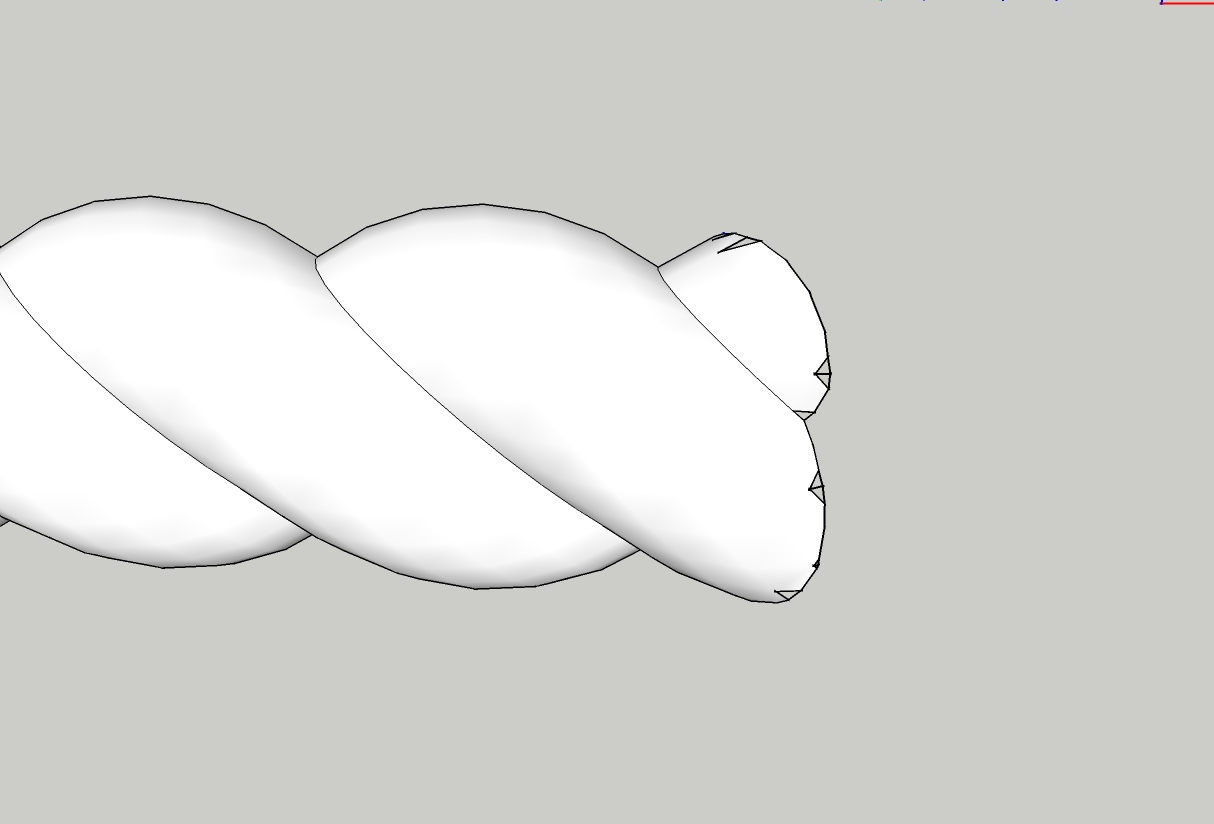

Hey David all went well at first and then this stated to happen i.e. fragmented miter joints. I have supplied an image so that you can see my issue, any ideas?

-

If you have very small faces [<~1mm] Sketchup/OpenGL has trouble forming them.

If the missing faces don't reform by drawing over one of the the edges of the 'gaps' try scaling the miter x10, trim it [it should then form without gaps], then scale down x0.1... -

Thank you Tig, works like a charm.

John

P.S. I love this site, thanks to everyone. -

John, as you've discovered, TIG is right on with his answer. He always is, though so there's nothing new there.

An alternative to the scale up and scale back down process that I find easier is to make a copy of the component and scale that up by a factor of 10 or 100. I'll edit that large copy of the component and then, when I am finished with it, I close it for editing and just delete the large copy.Whatever is done to the large one also gets done to the small one so there are no holes. Of course this doesn't work if you are making groups instead of components.

If you do opt for scaling up and then back down, make sure you grab the same scale handle for both scaling operations so that the component winds up in the same place as it was before.

-

Yes david I"m making components and thats a nice tip. Hope that I too have some useful knowlage to share.

John

Advertisement