Threads/upright extruder

-

Hello all,

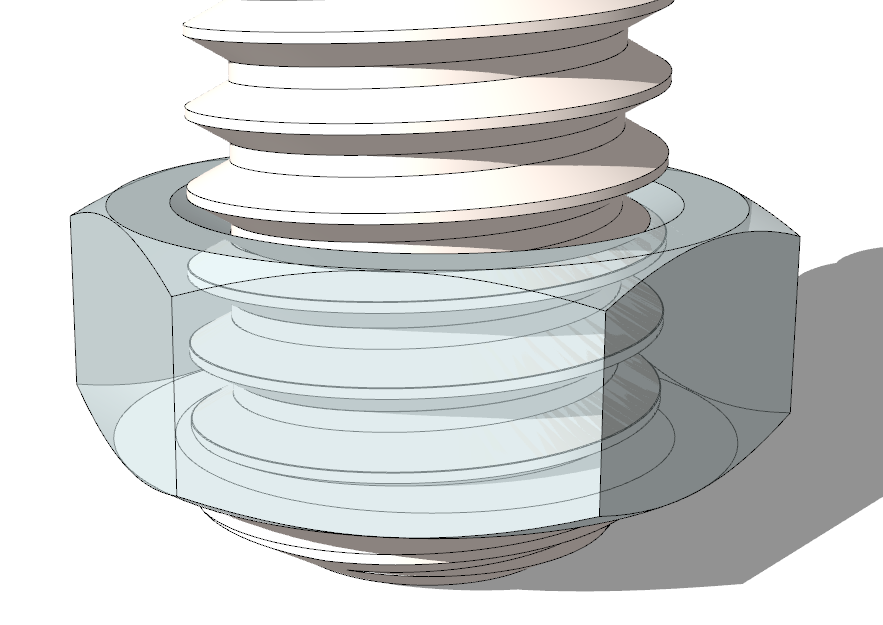

I do all sorts of work, and I find Sketchup to be the fastest. I appreciate the features of Fusion360, but I am trying to avoid using it due to slow modeling speeds. I am trying to create threads in Sketchup (3d-printing), and I have been able to do it the long way with multiple helixes and scaling. This takes way too long. I saw some info on using the thread profile along with Enoth upright extruder, and this seemed like a reasonable work around. The problem I am having is that the faces are not closing to make a solid. The face that would be the crest forms, and the inside of the helix forms a face. The thread flanks are not formed. I can go through and draw a line on top of the existing helix, and faces close, but again this is super time consuming. I have followed the tutorial I have found to a tee, so I am not sure what is going wrong. I am guessing it may be related to vector settings in teh upright extruder. Any help would be greatly appreciated. On a side note, I would bet someone could make a fortune with an extensions that simplifies the whole thread making process. FWIW I'm using SU21 on Windows 10. -

@bigdaver

what's file size of that model? just curious

-

Hi Rich,

It's 6 Mb all told.

-

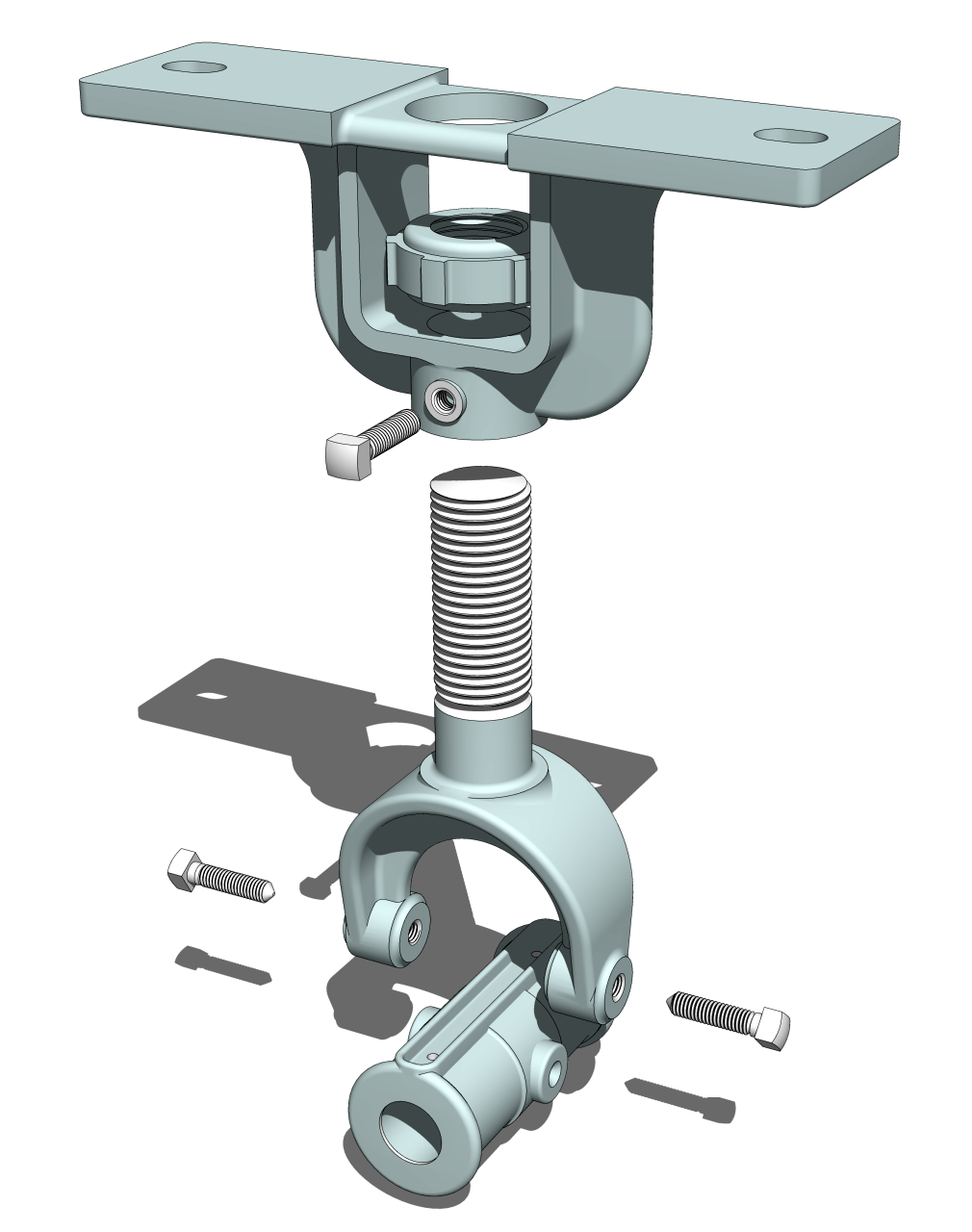

Another model in which the screw threads are created with Upright Extruder. All components are solids.

And for Rich, 7 Mb and 158210 edges.

-

Hi I’ve downloaded a few threads and they seem a bit tight , what is the best way to scale these to fit?

-

What do you mean by "download threads" and "too tight"?

I expect scaling them to fit will be much more work than modeling them correctly from the start.

-

From thingiverse

The nut is too tight on the bolt -

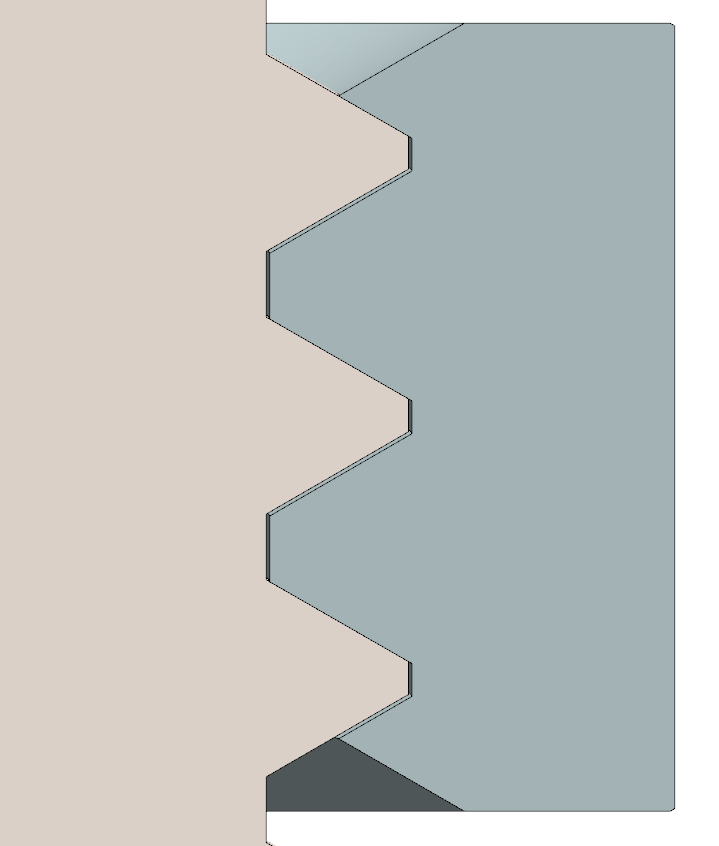

OK. So scaling them to fit is probably not the right thing to do. Do some reasearch on screw threads and look at how internal and external threads are dimensioned. They cannot be exactly the same size if you expect them to screw together. It's no different than a peg into a hole. If you expect to slide a peg into a hole it cannot have the exact same diameter as the hole.

Example:

The internal threads of the nut have to be be slightly larger to allow the screw to fit. The difference in size is determined by the thread tolerance class. If you put a nut on a screw you can feel the nut is very slightly loose on the screw.

Here I've modeled both internal and external threads and positioned the nut as if it was screwed down tight to something under it.

-

Hi yes i understand all that you say, but it would be a great idea if SU had a thread making feature, to speed up drawing

Not everyone is as good as you

Cheers dean -

Thank you for the compliment.

What I do is not at all difficult with the right tools. Like anything else in

SketchUplife you just have to learn how to do it.There is the EP Fasteners extension that will make screw threads. I prefer my process because I think I get nicer screw threads. For a program that was intended for architectural modeling, I think there are good options for modeling screw threads already.

Advertisement