Foundation Plugin

-

Currently the top of the slab is the origin. What do you mean by layers on top of the slab?

-

Certainly, juju, I'd assumed that a Medeek plugin would be moving towards all sorts of options: plinth wall, no plinth wall, raised floor,retaining wall, basement, garage (floating) slab...

-

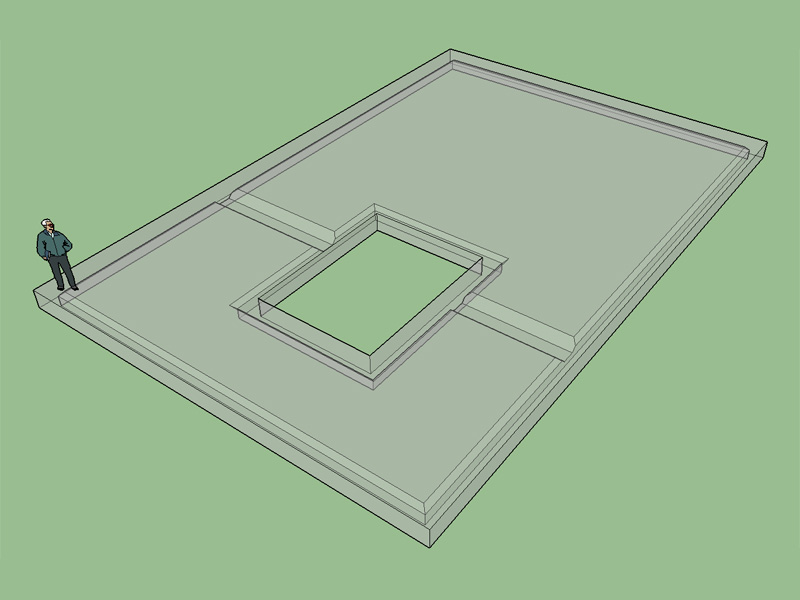

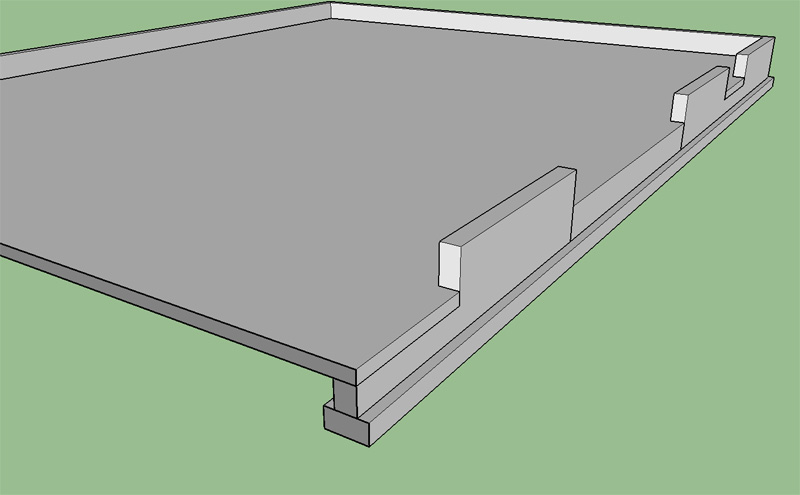

If the exclusion area is simply a hole in the slab then it is probably easiest just to push/pull a hole in the slab. However, if the exclusion area is a large opening with footings required at the perimeter then that is a different matter. It might look something like this:

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

Note how the opening bisects the interior footing, which does potentially complicate any algorithm that would generate the hole and perimeter footing. I will have to give this some more thought...

-

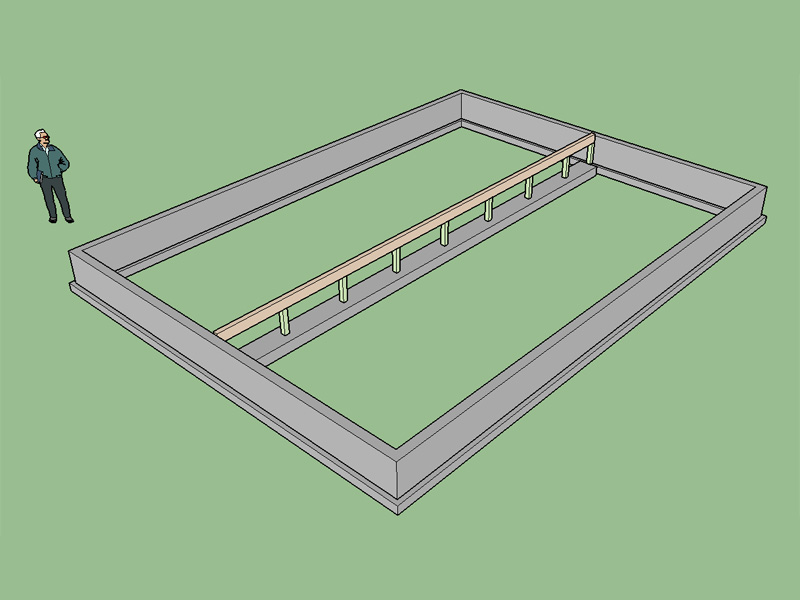

Typical stem wall foundation (crawlspace) with interior strip footing and floor beam. This is what is built locally around these parts (Ocean Shores, Washington):

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

Nice.

If the girder is only supporting the floor, around here we use isolated post and piers without the connecting footing.

-

I've seen the footings done both ways. Locally the majority of homes are built very close to the beach directly on sand with a high water table that fluctuates with the tides. The strip footing helps prevent shifting of the piers and posts and uneven settlement.

Out of curiosity what are the typical dimensions of your piers? and posts?

Some contractors locally like to use 4x4 posts and some default to 4x6 with a floor beam size of 4X8 fairly typical. When I do the engineering I will check the floor beams and posts as well as the soil pressure at the footing but I rarely encounter a problem.

-

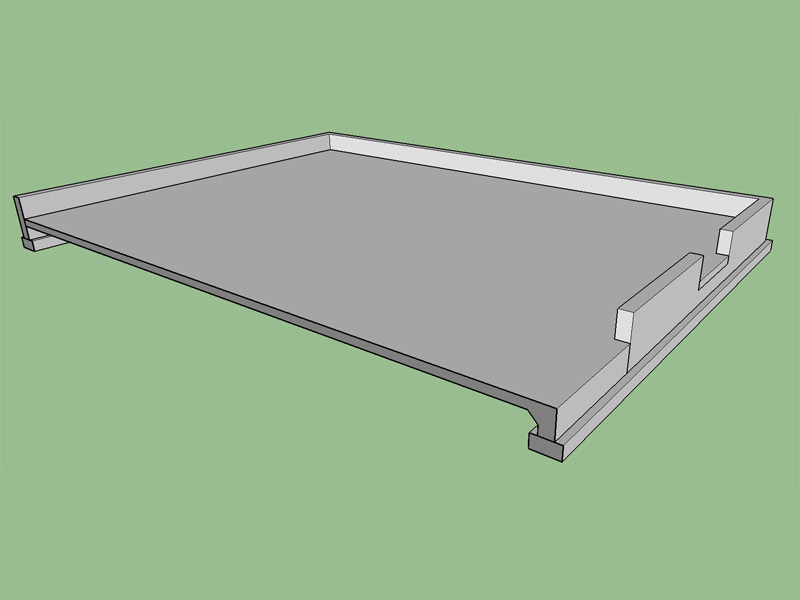

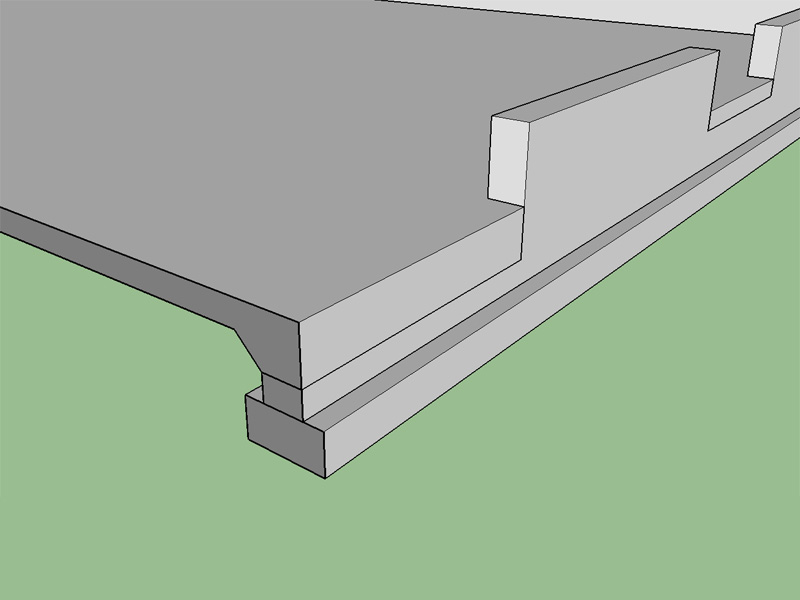

Version 1.0.2 - 07.08.2016

- Added stemwall foundation type (rectangular outline only).

- Enabled post and pier interior floor beam(s) with a strip footing.

- Added brick ledge option to stemwall foundation.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

The interior floor/footing assembly is grouped as a component so that adding extra floor beams or moving them is easily accomplished.

-

Something that will working with every start surface will be very fine!

(Flying Forewoman!

-

Would it be easier for a user to pick a number of points to describe a polygon or to have a tool that allows one to select an existing face as that polygon? I also need a stemwall tool that allows one to create single walls (curved or linear) since there are times where you do not want to create a closed polygon outline.

-

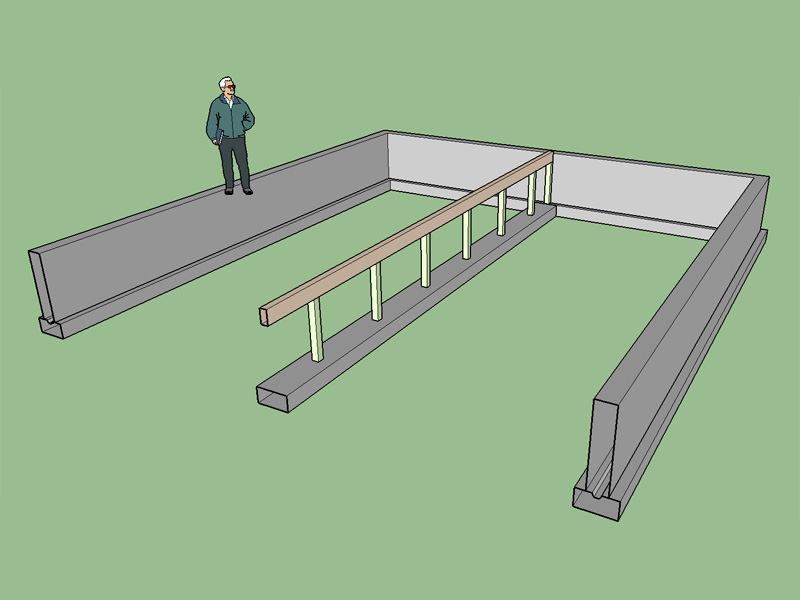

When the user selects a type B footing (stemwall foundation) a keyway is inserted between the stemwall and footing:

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

View Medeek skp models in 3D Viewer

When viewing plugin at given link such as

https://3dwarehouse.sketchup.com/model.XXXXXX

you can activate the 3D WebGL Viewer to inspect the 3D Model.

-

I'm trying to determine which is the preferred method of blocking out a stemwall foundation for garage doors where a slab will be poured in the garage. I've seen it done both ways. Option 1 does not typically block all of the stemwall out and seems to be more common in locations where the frostline is deeper (24" or deeper). Option 2 completely blocks out the stemwall at the garage door and then a thicken edge is poured where the slab meets the footing at the garage door. From a structural point of view which is the better method and also from a construction point of view what are the pros and cons?

Option 1:

Option 2:

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

I should point out I've also seen a sort of a combination of the two options where the blockout does not extend to the footing but a thickened edge is employed at the slab/door interface and the thickened edge is typically 2x the slab thickness, or called out as a minimum dimension of 8".

Option 3:

-

That looks like a better one. Then there's someone I am working with now who wants the slab floating and not resting or tied to the foundation at all. Preference could depend on soils.

-

If there is enough room between the footing and the slab I could see how one could omit the stemwall and have a layer of gravel, sand, soil between the slab and the footing at the opening. I have never seen a slab poured that way at the garage door opening but it doesn't mean it can't be done. I supposed one could even go so far as omit the footing across the opening as well but from a structural standpoint I would highly discourage that, much better to tie the building foundation together at the perimeter with regard to lateral loads.

-

Option 1 is what I have used many times. Never the others. Frost depth 2 to 3 feet typically.

-

The blockout methods seem to be all over the board, I've even talked with some of my engineering friends and the response is mixed there as well. I guess I just need to provide the option for any of these three configurations within the plugin. Sometimes I feel that I get bogged down in the details but I hope some of this level of detail is appreciated.

The other issue I'm having with slabs within garage spaces is the slope of the slab. I'm trying to determine if is worth trying to incorporate a slope into the slab as it would actually be poured. As far as I know there is not a minimum slope specified for garage floors in the IRC 2015 or earlier only this fairly general statement:

[highlight=#ffffcf:1d83tmnb]The area of the floor used for parking of automobiles or other vehicles shall be sloped to facilitate the movement of liquids to a drain or toward the main vehicle entry doorway.[/highlight:1d83tmnb]

Typically the garage slope is 1/8" per foot or 1:96, how critical is this to you the user of the plugin? Flat would be easier to program but then your blocked out entries on the side of a garage would be only theoretical.

-

A few observations ...

- In residential construction here in central California the norm is to pour the garage slab monolithically with the footings. Some builders will pour the footings and stems first and then come back with the garage floor slab, but there aren't many. Our frost depth is very shallow.

- My preference for sloping of the garage slab is to have a 3-1/2" drop at the top end below the residence's finished floor slab and sloped down to 5-1/2" at the garage door end.

-

My feeling about slopes is that I absolutely want to model them. There are a lot of instances where having the real slope gives you valuable information with regard to the actual construction. A case in point would be - What is the real height of a deck beam. I would rather have this information on the drawing or model rather that having the carpenter figuring it out on the jobsite.

With respect to garage slabs, I usually have the slab 2" min below the adjacent house floor with a 2" slope from the back of the garage to the garage door. -

And where do you set the floor height from. Usually I end up working out what is best at the rear of the garage and sloping from there.

Advertisement