Thickness

-

Hi everyone,

I'm looking to 3d printing for the first time. I'm making a small box for a station, and I originally had thickness to 5-10mm. The volume ended up being really high (for the cost of printing) and I'd like to know how thin can a wall for a box be and still have strength to hold everyday small things: coins, cell, erasers and everyday things you'd find on a desk.

I've uploaded the model, if you have any suggestions or spotted any mistakes that I would need to fix before printing, that'll be appreciated.

Thanks!

-

Which material?

-

Use thomthom's Solid-Inspector, temporary section-cuts and Xray mode to edit shown issues.

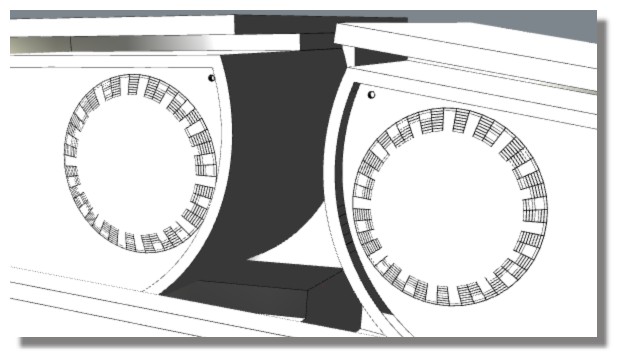

The snap shows the issues - face-less edges and disk-faces with perimeter edges with 3 faces....

To reduce wall thicknesses [to say 3mm - depends on the intended material!] use a section-cut or Xray mode to access the interior and then select the inner faces and Move them a few mm or use Scale around its center [Ctrl]...

-

Seems straigt lines on the eyes are unnecessary at this size !

-

Thanks for the quick response guys.

The local 3d printers in my area have ABS, PLA and Resin. Any suggestions? PLA seems suitable for this as it seems to be stronger and less bendy.

-

Hi TJ, welcome to the forum!

For printing in ABS or PLA on a model this size, 2 mm thickness would be a good start. For large flat walls, maybe adding 5mm thick ribs every so often would be a good idea to add strength.

-

Reducing the volume of material might not reduce the cost as much as you would hope. A lot of times the high cost is due to all the other factors: time, space in the printer, cleanup...etc.

AND, be aware that there is a huge difference in how much printing services charge from one to another. I've seen astronomical prices from smaller local guys compared to what you will get from places like imaterialise.com

Advertisement