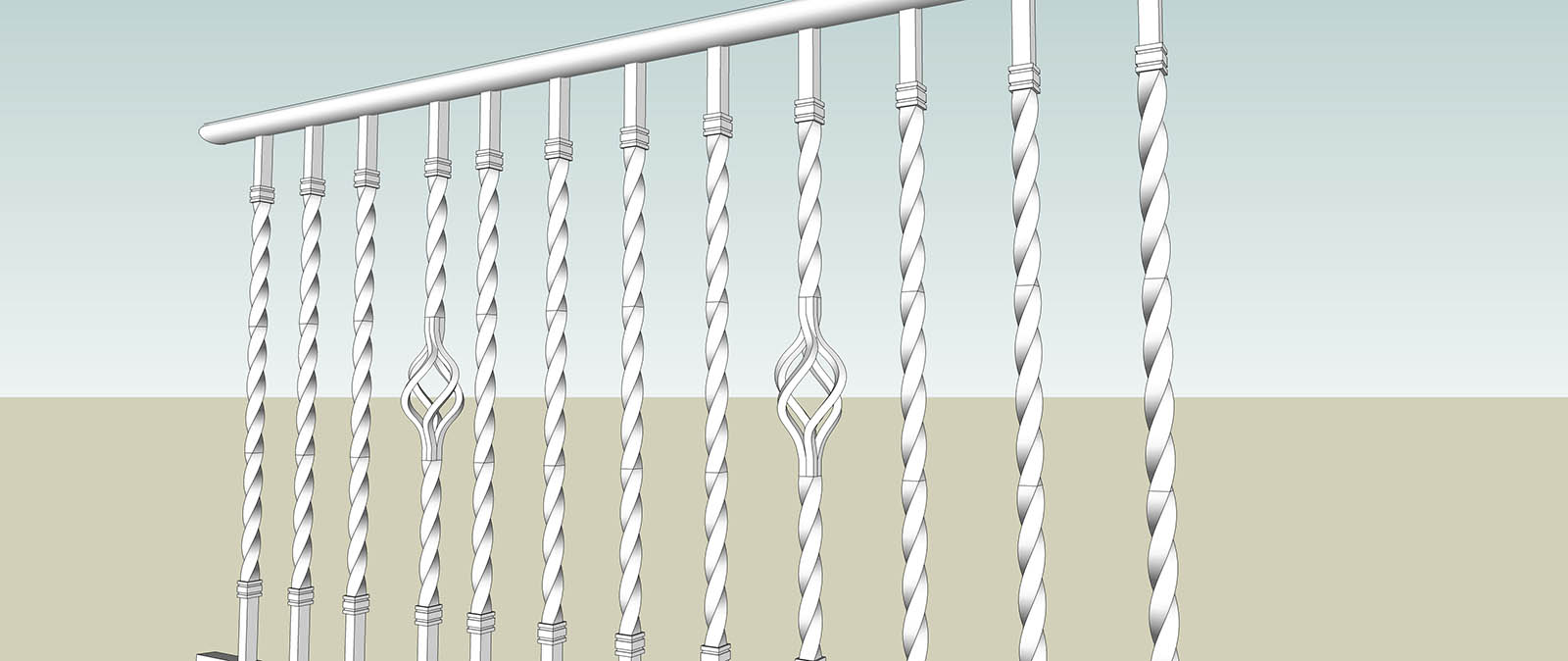

Working with wrought iron

-

I second http://www.drawmetal.com/tapermaker since it is made specifically for this purpose by somebody who does it for real.

Best,

Jason. -

@hellnbak said:

That really was cool. So tell me, I assume the bar was made up of four bars, so how was it made "solid" except for the section that was twisted?

A traditional basket twist is made from one solid bar.

You first have to heat the section you want to twist and cut it into four sections using a chisel.

This takes quite a while and a lot of reheating. Then knock the four new bars back into place and then do the twist. -

@dave r said:

They're welded together by black dwarfs in underground caves.

Yippeeee!!! In Middle Earth, right?

-

-

@box said:

A traditional basket twist is made from one solid bar.

You first have to heat the section you want to twist and cut it into four sections using a chisel.

This takes quite a while and a lot of reheating. Then knock the four new bars back into place and then do the twist.Wow, they actually did this? How the heck did they ever turn a profit?

-

That's why you have apprentices, or badly paid slaves, I made too many of them to think about.

-

@box said:

That's why you have apprentices, or badly paid slaves, I made too many of them to think about.

Just out of curiousity, about how long would it take to make one using that method?

-

We used to knock one out in about half an hour, but that was many years ago now, very much doubt I'd still be able to make one.

I was in an old steam locomotive workshop so we had great forges and foot controlled pneumatic hammers which made life much easier.

Getting the heat right takes the most time, the actual metal work part is quite quick, as you have to work fast before it cools.I found a video for you of a guy making his first one.

http://www.youtube.com/watch?v=X62dDh_9on0 -

@box said:

I found a video for you of a guy making his first one.

That video was great! I have the greatest respect for those that created such works of art using those methods. Nowadays I suppose they use "modern" methods to mass produce such items, but I'm also sure the result lacks the character and natural imperfections that made the originals so special. Just try to get a kid to learn a craft like that today -- he wouldn't understand it if it didn't involve microchips and a touchscreen.

Thanks again. -

Check this out: http://www.pbs.org/woodwrightsshop/video/3000/3013.html

-

Thanks Dave. Funny you should point me to that particular episode, I caught it just a couple of weeks ago on PBS (I think). Well, I caught the last half of it, so now I was able to see what I missed. What really bothers me about that guy is how disorganized he is. His shop is always a total mess, can never find what he needs. But he seems to enjoy his work, so what the hey.

-

I've always enjoyed watching Roy Underwood in his shop. Yes, it is a bit cluttered but so is mine. I fell right at home in his shop. The problem for me is that they do those shows in his shop with one take. I find I'm almost as out of breath as he is at the end of it.

-

I know what you mean. While Norm Abrams is a great guy and craftsman, his shop is so unrealistic -- everything spotless and organized in a building bigger than my house, with every tool ever made and all top of the line. They need to make a show that uses only the tools you might find in in an average garage workshop, so you can concentrate on how things are being done instead of drooling all over your TV when you see all the play-purties he's using

-

@hellnbak said:

his shop is so unrealistic -- everything spotless and organized in a building bigger than my house, with every tool ever made and all top of the line.

standard TV formula.. product placement and whatnot.. (i.e.- it's not like norm is buying all that stuff)

p.a.-s to clean up afterwards etc..ah.. the life of a TV craftsman..

-

Dave,

I am trying to make correctly the metal basket twist. I was able to make the spiral using "drawhelix" but to come out of the spiral at top and bottom is a challenge. I had drawn straight lines on top and bottom of the spiral and tried to use a 2d fillet radius which did not work for me. What method(s) did you use to transition the spiral to the vertical?

Thanks! -

I made a tutorial of how I did it a long time ago. Maybe it will help?

-

Thanks Dave!

Your instruction help tremendously. Instead of using bezier curve to make the arc I used the native arc tool and weld with same result.Lapx

-

Nice job! QUICK study.

-

@lapx said:

Thanks Dave!

Your instruction help tremendously. Instead of using bezier curve to make the arc I used the native arc tool and weld with same result.Lapx

nice.. looks good

Advertisement