How to get from 3D model to 2D construction plans?

-

Maybe section cuts together with TIGs plugin SectionCutFace will help you.

Often it is helpful to use parallel projection (menu -> camera) with the standard views (front, left, top, ...). -

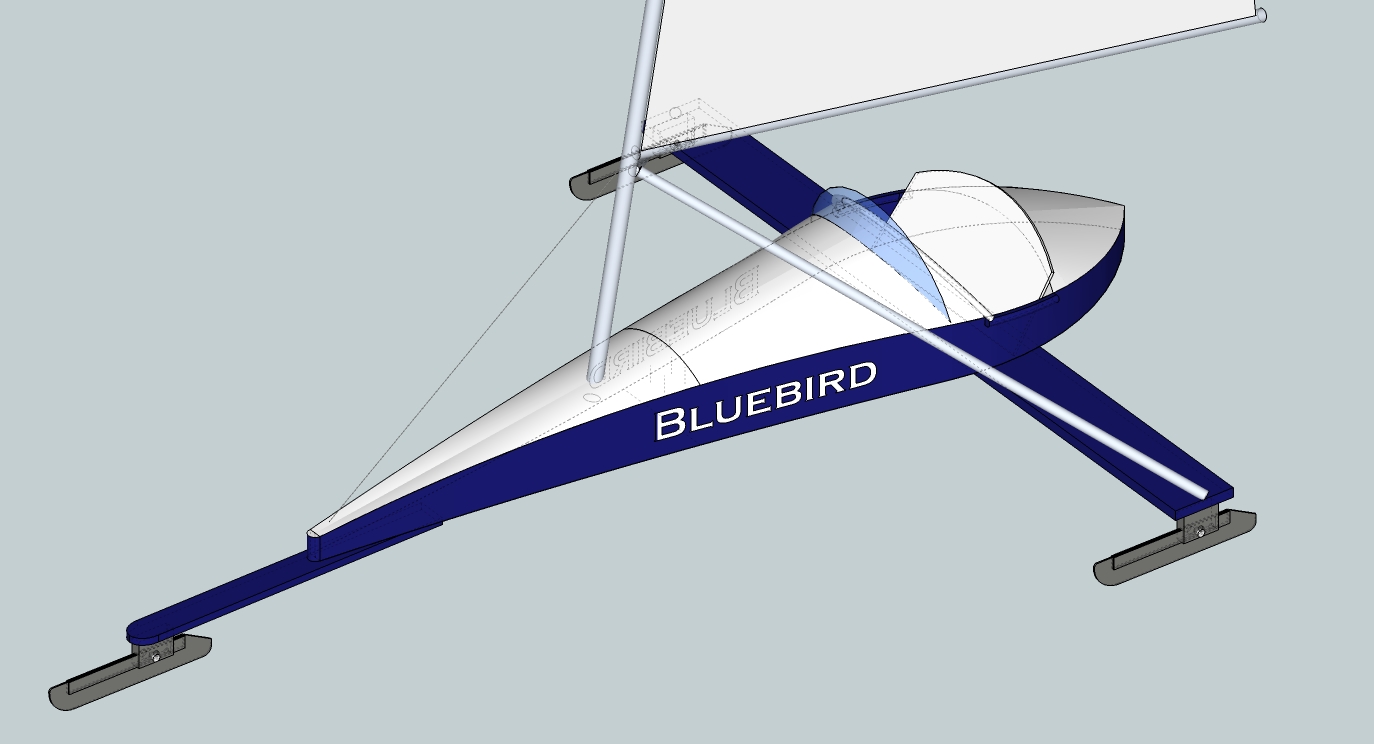

Cool looking ice boat.

I think a lot of the labor reduction will come in the way you make your components. You can use strategies such as setting the orientation of the component axes to aid in laying them out for patterns. As to flattening the skins, you can use any of several unfolding plugins (see the Plugins list--red button at the top) but keep in mind, the precision will be impacted by how many segments you've used to approximate the curves you draw.

LayOut from the pro SketchUp package would be a big help for this so you might want to investigate that.

How do you plan to layout and cut the skins? Are they thin plywood? Veneer? Is the boat cold molded? So many questions but a lot of what you need to do will be driven by what information is needed to create the parts.

-

@dave r said:

Cool looking ice boat.

I think a lot of the labor reduction will come in the way you make your components. You can use strategies such as setting the orientation of the component axes to aid in laying them out for patterns. As to flattening the skins, you can use any of several unfolding plugins (see the Plugins list--red button at the top) but keep in mind, the precision will be impacted by how many segments you've used to approximate the curves you draw.

LayOut from the pro SketchUp package would be a big help for this so you might want to investigate that.

How do you plan to layout and cut the skins? Are they thin plywood? Veneer? Is the boat cold molded? So many questions but a lot of what you need to do will be driven by what information is needed to create the parts.

Hi Dave,

The two-seater iceboat will be made from 5 mm plywood. And some doubled up reinforcements of 15 mm. The bottom is flat, sandwich of 2 x 5mm ply and 15 mm foam in between and some solid ply reinforcements. The sides are three layers of 5 mm ply scarfed together and laminated to the sides of the bottom and the fixed bulkheads. The yellow bulkheads in the pic are temporary, just there to assist in shaping and laminating the sides. If the boat is not stiff enough in way of the cockpit, an extra layer of 5 mm ply is laminated to the inside of the sides. Decks will be 5 mm ply. The mid deck will be removable so you can access the steering gear on the cockpit floor and when sailing without cover maybe have space to take a child between the knees when sailing.

For now this is a one-off project so the parts will be sawn by hand. I will probably be building two boats side-by-side and sell one to recover the costs. If it works out well, I perhaps offer the plans and building instructions or a kit for sale. This iceboat is designed to use standard DN iceboat hardware and a standard Laser dinghy rig supported in way of the boom by one stay and two struts.

While making the model I spend lots of time calculating strengths, weights and dimensions to keep the total weight low while having a strong enough structure. Total weight of the fuselage (including epoxy resin and glass sheathing, ex hardware) is now a little over 45 kgs. Heavy, compared to a DN iceboat (21 kgs). But my design is a two-seater tourer, not a racer. But perhaps I'm still over-dimensioning. For stability and sailing weight distribution calculations I used the Center of Gravity (CoG) plugin. First separate CoG's for the wood parts, the rig and the crew, next a combined CoG based on the three.

In SU, I flattened the skins with the 'Unfold tool' plugin, after first creating the skins with Fredo6's Curviloft. Cool plugin that is! Unfolding was lots of work with so many small triangles making up the decks. To check accuracy of the unfold action, I measured the tops of the bulkheads to see if the flattened deck skins were wide enough. They were.

I first made the mistake to make components of the bulkheads, then copy them and rotate them flat. Next I removed the top surface and lines (bulkheads were 5 mm and 10 mm thick) to create a flat pattern....et voila.... the original component was taken apart too! I learned when to use components and when groups!

I started the model by integrating two 'coffins' - rectangular boxes -, one with the horizontal curves and one with the vertical curves and then erasing all lines and planes outside the desired shape. Was like cutting through a block of styrofoam with a hot wire. Then I created the bulkheads with the curved tops and layed skin on these to form the decks.

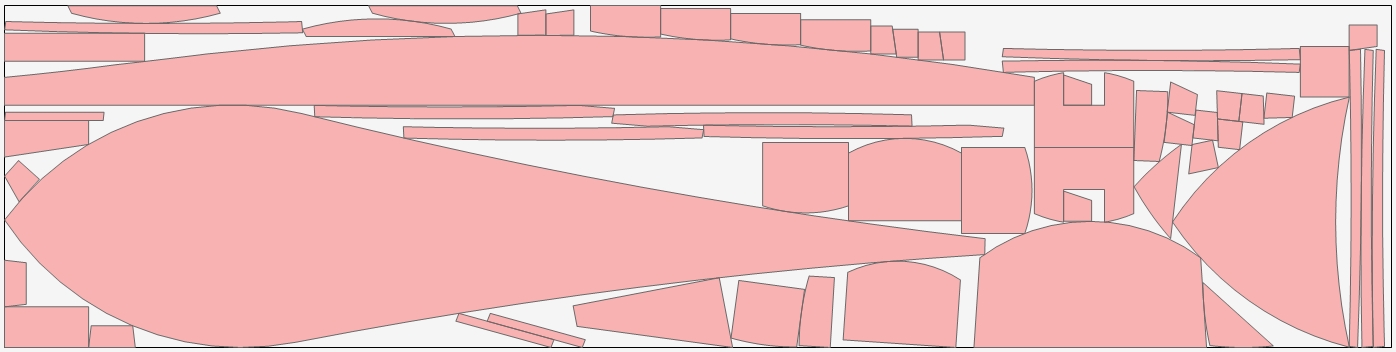

I used the demo version of Astra true shape nesting to nest all the parts on plywood sheets. Below is a pic of an automatic nesting operation done by Astra. It's a double length sheet first scarfed together. In the demo version of Astra you can't export .dxf files for laser cutting, but you use the pic (a screenshot) to get an idea of an optimal nesting. I use the Grid plugin to lay out all the parts on a 5 cm x 5 cm grid in SU. Then I will print this on A4 paper and with the grid as guidance, draw the parts on flipover sheets with a true grid of 5 cm x 5 cm. Symmetrical parts have to be drawn only in half parts.

And to all other respondent: thanks for your assistance, I'm going to look into every tip.

Mike.

-

Hi Michel,

That sounds like a great little ice boat. I bet it'll be fast for what it is. A friend and I have talked about ice boats. The trouble is around here, the ice usually isn't very nice for that. This winter it has been so mild that most of the lake has been open or only just skinned with ice so I doubt there was much ice boating at all.

It sounds like you have most everything planned out. I wonder if you might find Delftship better for developing the skins. If you had the pro version of SketchUp you could export a file you could open.

As to the bulkheads, I wouldn't have bothered to edit them to 2D when you lay them out. If you set the Camera to Parallel Projection, you won't see the thickness anyway. Personally I would still use components instead of groups. I would set the axes for the bulkhead components so they are at the center on one face of bulkhead. Then, to do the layout of them, I would drag them in from the In Model component library and drop them onto a rectangle drawn vertically that represents the sheet of plywood. There's no reason to have to lay the components down flat onto the ground plane, afterall. Does that make sense? If not I can make an example. OR, if you want to send your SKP by PM, I'll do it with your model.

-

Hi Dave,

About not laying the parts flat but slap them vertically against a sheet.....good thought. I am still lacking in 3D thinking, that's clear, indeed there is no need to turn parts flat on the floor. Removing the thickness of the bulkheads and turning them into a simple line drawing was necessary to get the part as .dxf into Astra for nesting. So I have to find out if I can use the Grid plugin to make a vertical grid. I really need a scalable grid around the parts to be able to convert them to full size saw patterns.

I'm amazed that at your location (Minnesota, right?) the ice was so weak. We've had ice here in the Netherlands for the third year in a row, after 8 years of mild winters without ice. A little ice age now, if you ask me. So I thought it's about time to finally invest in building an ice boat. I've sailed a borrowed DN for a day 30 years ago, and I still remember that day as if it were yesterday, an unforgettable experience!

Here's another teaser for you to start on an iceboat too.

Cheers!

Michel

-

Now cut that out! You're going to make me build an ice boat aren't you? I want to build a little double-ender (15-16 feet long) next.

Yes, I was surprised by our lack of real winter here this time around. Last winter was cold with lots of snow much like those I remember as a child. The problem here is that even with winters like that, there is so much snow on top of the ice that you'd need skis on your ice boat. And then there's the pressure ridges that form making for a bit of excitement. On the other hand, when the ice is good, you could sail for perhaps miles without tacking.

Here's an aerial view of part of the lake.

The lake is more than 20 miles long and in most places more than 1 mile wide. In the photo you can see the marina where I keep my sailboat. Her slip is in the near basin. If you look close you can see a bend in the nearest row of boats. My boat sits right at the bend.

Anyway, here's a few suggestions for you. Leave the parts as components. Set their axes to some logical point. That may be dead center or it might be centered at the bottom. When you are ready to lay them out for cutting, put them on a vertical plane as I mentioned before. If you want to have a grid, that's fine but you may not need it. Once you've placed the bulkhead/frame components, Select the plane and use Intersect Faces>With Model. This will result in the edges of your bulkheads being transferred to the face of the plane. Now it's that which you'll export to Astra. This leaves your bulkheads and frames intact and, by leaving them as components, you still have the ability to make modifications in the model that carry through to the bulkheads laid out on the plane if you need to. You just have to replace the large plane before running Intersect again.

By the way, I'd like to see photos of your build process and of the finished boat. And if I ever end up in the Netherlands when there's ice, I want a ride.

-

Dave, nice lake, from this distance it looks a bit like the lakes in Northern Italy, but with a larger marina.

You made me aware of the benefit of using components in stead of groups, if I need to alter the model, the panels on the grid change with it. I hadn't seen that as a benefit, more as a disadvantage.

Another problem I have is the fuselage sides. In the model they have texture, but zero thickness. In real life they will be 15 mm of 20 mm thick. The connection between decks and sides is not constructable in the way it is in the model now. In reality the sides need to be tapered down to receive the deck edge and the shape of the bulkheads changed perhaps but I don't see a way to model that without thickening up the sides. The sides are single curved, if you look from above, they have a shallow S-curve. I can't push/pull them to a thickness because of this curve. Do you see a way to thicken the sides to real life proportions?

Michel

-

It is a pretty nice lake. Techincally it's a wide area in the Mississippi River.

So to thicken the skin to represent it's real thickness, you could use Joint Push/Pull. Hit Tab before starting the push/pull operation and choose Thickening. That ought to get you what you need for the skins.

There are many benefits to using components in your model but the editing thing is huge.

TTFN

Dave

-

Dave, another great tip, the joint push/pull plugin! Many thanks! I should have known this weeks earlier.

Michel

-

-

Wow

That's superb Dave

-

What? The lake? I didn't make it.

-

The crib. It's really nice.

-

Thank you. It was fun to build, too. The planks are clear pine that I resawed and planed to 1/8" thick. It's amazing how strong it is considering how thin the planks are. The worst part was planing the rolling bevels on the planks and the gains at the ends. The planks are so thin, it only took a couple of swipes with the plane to cut them. It was easy to get too much off.

-

That's a sweet little swinging bunk!

Michel

-

Thank you Michel.

-

Hi MichelC

I think I could help.

I am busy with creating tools to make paper scale models in Sketchup.

You can see examples how my scripts work here: http://www.screenr.com/user/SketchupPP

In fact it covers quite a lot of what you are asking for.One thing that is missing is a nesting algorithm, but it is very complex story.

Greets

Matt -

I have a related question. Is there a way to export a picture from SU that would eliminate perspective distortions (parts of a model that are further away look smaller), so all visible surfaces of the model in the exported picture keep their “true” size? For my purposes the model doesn’t have to be unfolded into its various parts, just a flat picture. Does that make sense?

-

Chad, you can set the camera to Parallel Projection. Look in the camera menu. Perhaps that will do what you want? another thing you can do is reduce the "wide angle" distortion by adjusting the field of view. Select the Zoom tool from the Camera toolbar. The measurements box will indicate either an angle of view or a focal length (degrees or mm). You can enter a low angle of view or a higher focal length to reduce the appearance of things receding into the distance.

Here's an example:

-

Yes! Switching to parallel projection did the trick. Thanks!

Advertisement