@dave r said:

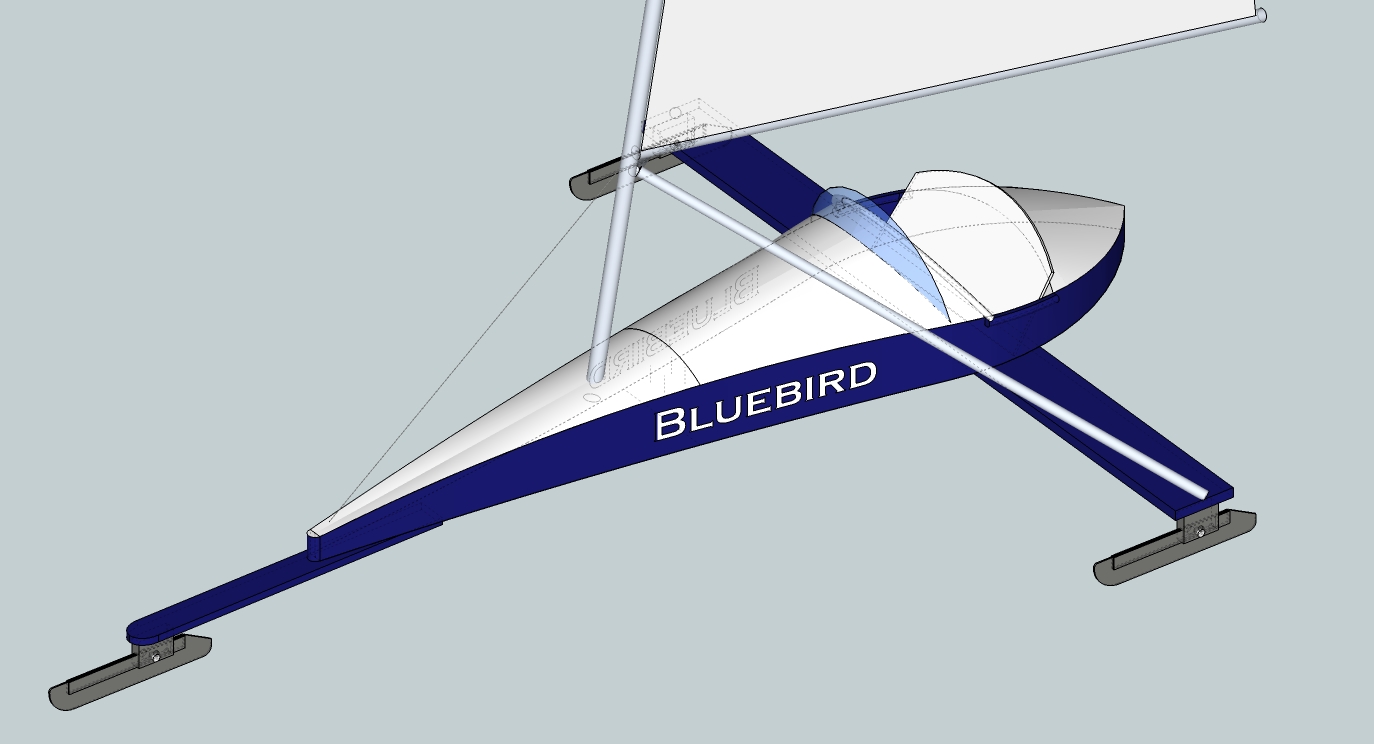

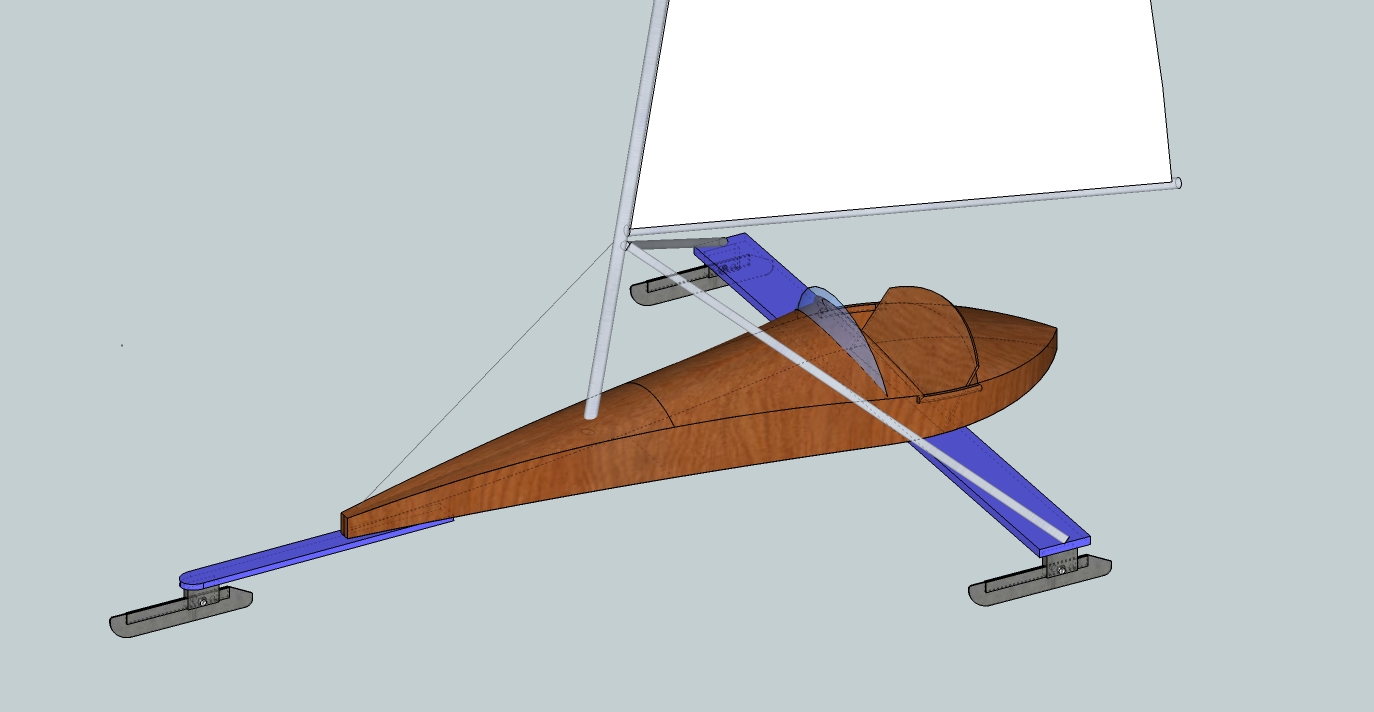

Cool looking ice boat.

I think a lot of the labor reduction will come in the way you make your components. You can use strategies such as setting the orientation of the component axes to aid in laying them out for patterns. As to flattening the skins, you can use any of several unfolding plugins (see the Plugins list--red button at the top) but keep in mind, the precision will be impacted by how many segments you've used to approximate the curves you draw.

LayOut from the pro SketchUp package would be a big help for this so you might want to investigate that.

How do you plan to layout and cut the skins? Are they thin plywood? Veneer? Is the boat cold molded? So many questions but a lot of what you need to do will be driven by what information is needed to create the parts.

Hi Dave,

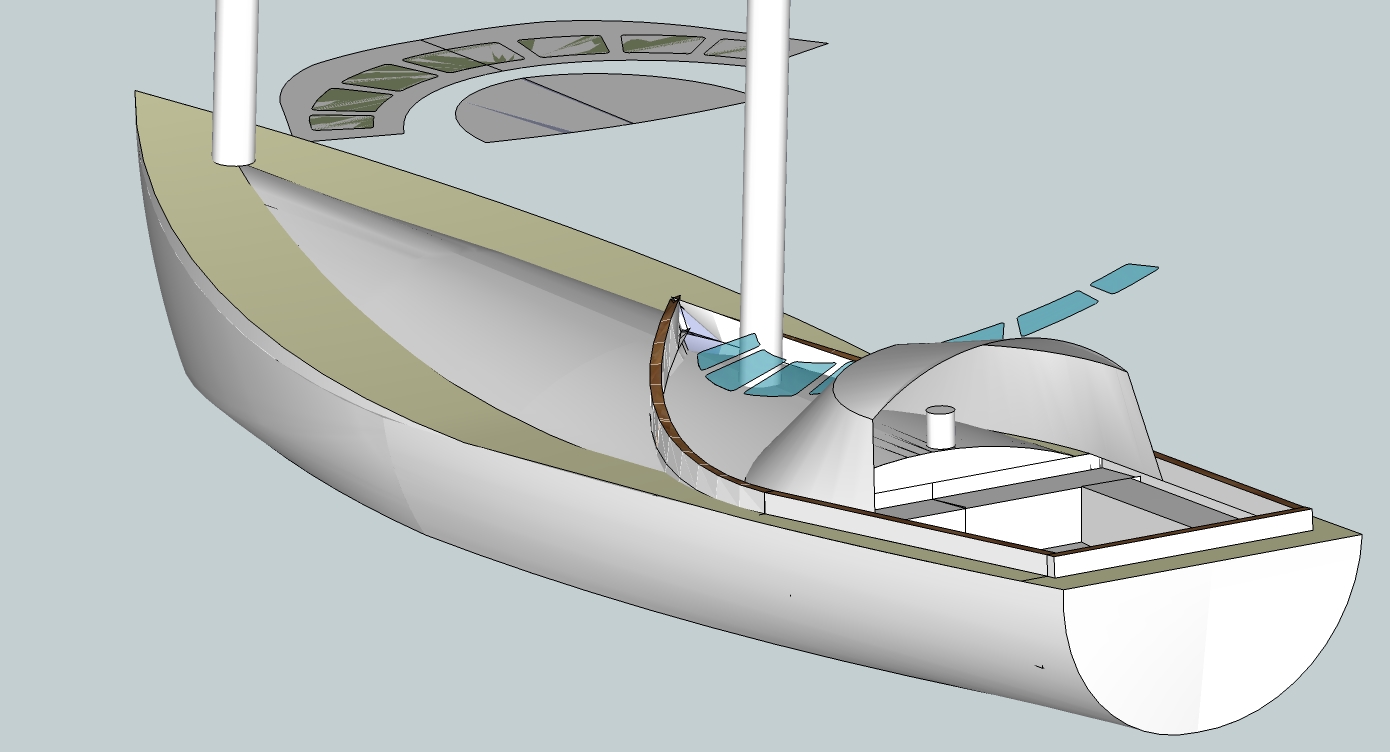

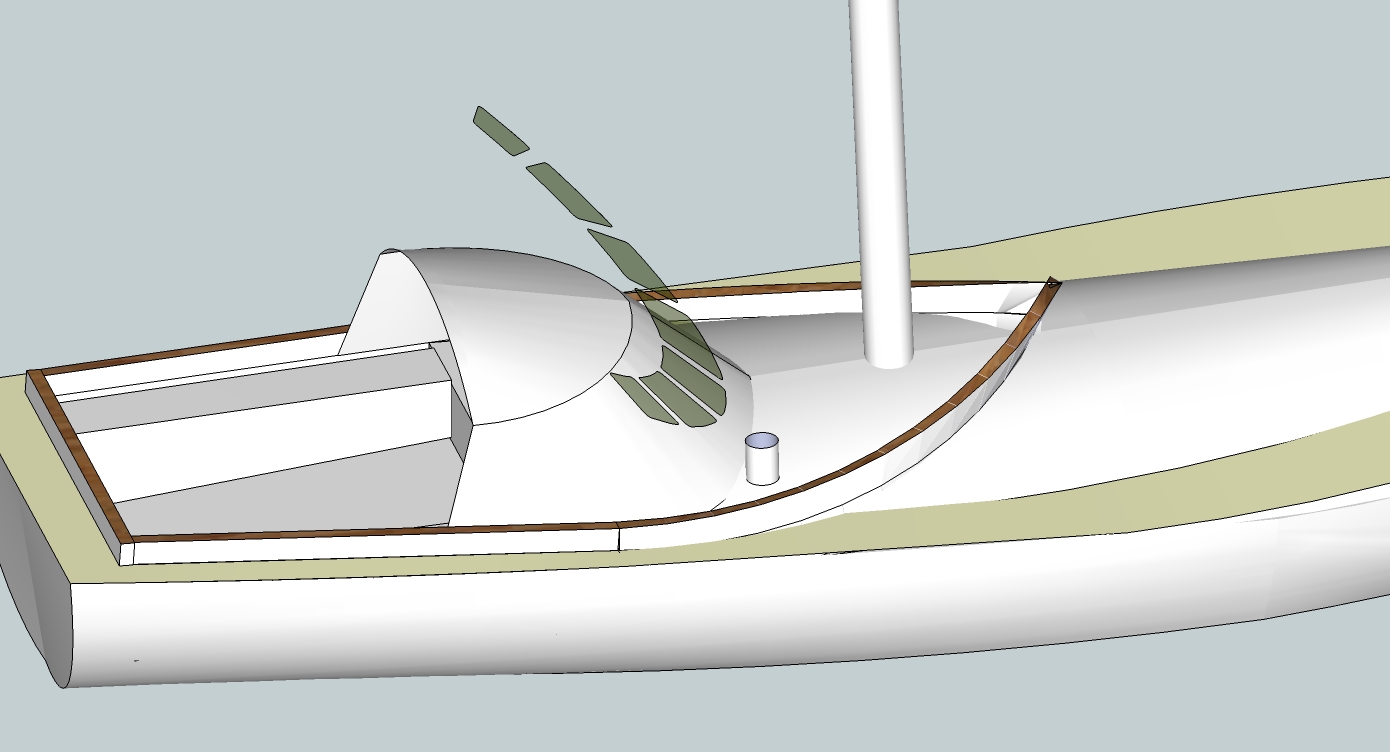

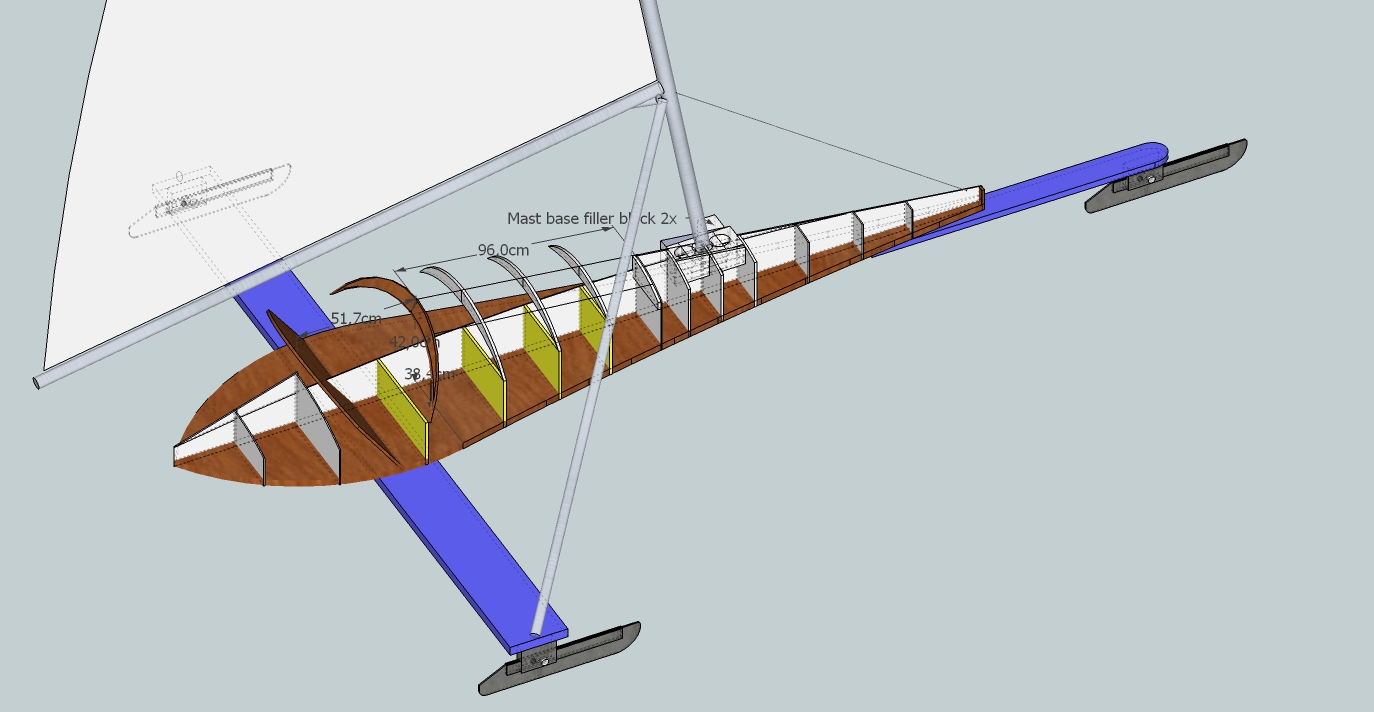

The two-seater iceboat will be made from 5 mm plywood. And some doubled up reinforcements of 15 mm. The bottom is flat, sandwich of 2 x 5mm ply and 15 mm foam in between and some solid ply reinforcements. The sides are three layers of 5 mm ply scarfed together and laminated to the sides of the bottom and the fixed bulkheads. The yellow bulkheads in the pic are temporary, just there to assist in shaping and laminating the sides. If the boat is not stiff enough in way of the cockpit, an extra layer of 5 mm ply is laminated to the inside of the sides. Decks will be 5 mm ply. The mid deck will be removable so you can access the steering gear on the cockpit floor and when sailing without cover maybe have space to take a child between the knees when sailing.

For now this is a one-off project so the parts will be sawn by hand. I will probably be building two boats side-by-side and sell one to recover the costs. If it works out well, I perhaps offer the plans and building instructions or a kit for sale. This iceboat is designed to use standard DN iceboat hardware and a standard Laser dinghy rig supported in way of the boom by one stay and two struts.

While making the model I spend lots of time calculating strengths, weights and dimensions to keep the total weight low while having a strong enough structure. Total weight of the fuselage (including epoxy resin and glass sheathing, ex hardware) is now a little over 45 kgs. Heavy, compared to a DN iceboat (21 kgs). But my design is a two-seater tourer, not a racer. But perhaps I'm still over-dimensioning. For stability and sailing weight distribution calculations I used the Center of Gravity (CoG) plugin. First separate CoG's for the wood parts, the rig and the crew, next a combined CoG based on the three.

In SU, I flattened the skins with the 'Unfold tool' plugin, after first creating the skins with Fredo6's Curviloft. Cool plugin that is! Unfolding was lots of work with so many small triangles making up the decks. To check accuracy of the unfold action, I measured the tops of the bulkheads to see if the flattened deck skins were wide enough. They were.

I first made the mistake to make components of the bulkheads, then copy them and rotate them flat. Next I removed the top surface and lines (bulkheads were 5 mm and 10 mm thick) to create a flat pattern....et voila.... the original component was taken apart too! I learned when to use components and when groups!

I started the model by integrating two 'coffins' - rectangular boxes -, one with the horizontal curves and one with the vertical curves and then erasing all lines and planes outside the desired shape. Was like cutting through a block of styrofoam with a hot wire. Then I created the bulkheads with the curved tops and layed skin on these to form the decks.

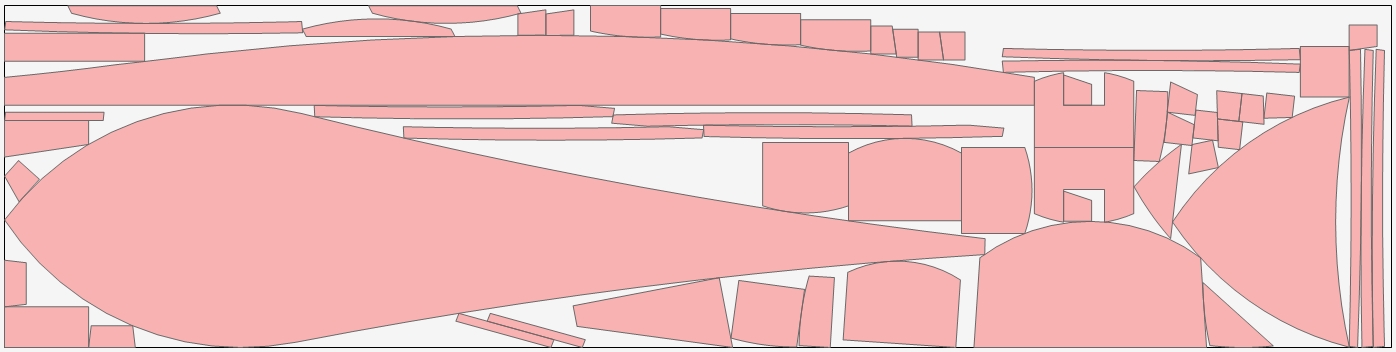

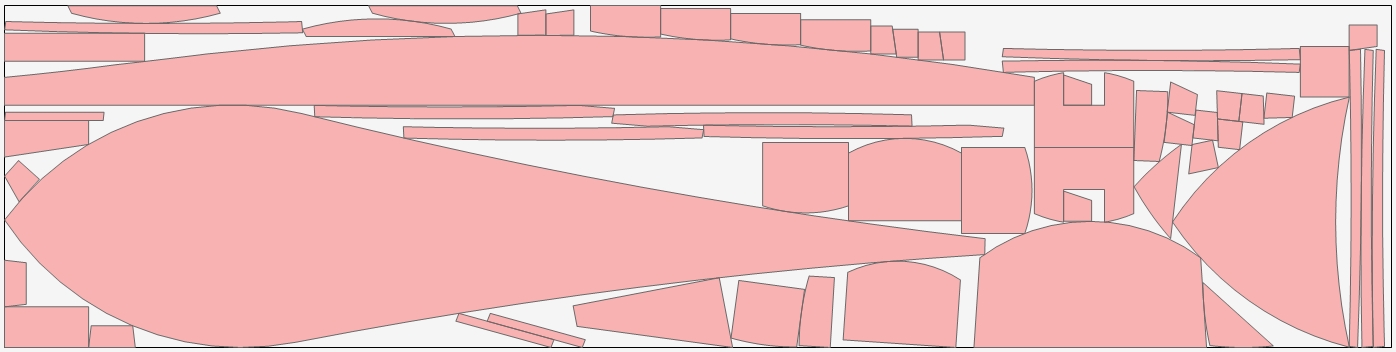

I used the demo version of Astra true shape nesting to nest all the parts on plywood sheets. Below is a pic of an automatic nesting operation done by Astra. It's a double length sheet first scarfed together. In the demo version of Astra you can't export .dxf files for laser cutting, but you use the pic (a screenshot) to get an idea of an optimal nesting. I use the Grid plugin to lay out all the parts on a 5 cm x 5 cm grid in SU. Then I will print this on A4 paper and with the grid as guidance, draw the parts on flipover sheets with a true grid of 5 cm x 5 cm. Symmetrical parts have to be drawn only in half parts.

And to all other respondent: thanks for your assistance, I'm going to look into every tip.

Mike.