From SU to papermodel - Thickness of paper issues.

-

@bjornkn said:

And you don't fancy cutting edges with a passepartout knife, like this one : http://www.modulor.de/shop/oxid.php/sid/cef5e8b50b1dcdcd6f7d628b4e63bd8b/cl/details/cnid/LAN/anid/LANE ?

Cutting 300 hard 4mm+ cardboard with a knife isn't exactly fun...

I've built some laser cut model airplanes, and they were engraved with the laser too. That would make it easier to find the paired edges? This could also be burnt outside the parts, on the cutoffs?

Basically this is just a question of building a good layout system, that makes it easy to assemble afterwards. You could maybe burn some notches or holes to make it easier to keep track of the trimmed/non-trimmed parts?I never heard about a passepartout knife before, it might be handy later on, but for now I need the simplest route to getting this model done

You're right the engraving could be very useful - I just need a very clever plugin to help make this layout system.It still confuses me a bit which parts to trim and not, if I have the corner of a cube, do I trim 1 side and 1 end of the top part... hmm I think it's doomed to go wrong if I should figure this out manually. My structure compares to a large swiss cheese so there's so many parts that needs to be processed by my brain.

-

You don't need any plugins, and I don't think there are any anyway.

What you need is a plan - and stick to it.

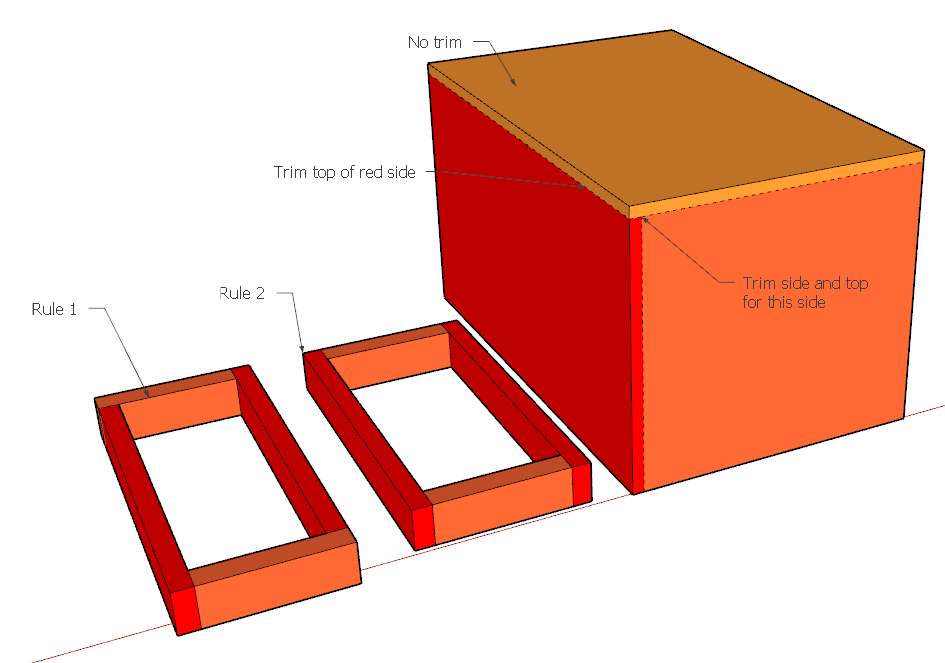

This is how I would trim a corner on a cube.

Some rules?:

Never trim a top face (looks ugly too)- Always trim left side (if needed)?

or 2. Always trim both sides (if needed)?

With Rule 2 it may be easier to avoid sheared models?

The image shows rule 1 though.

- Always trim left side (if needed)?

-

The problem with these trimmed methods is that if you need to use thicker/thinner cardboard, balsa, foamboard or whatever, you'll have to redo your plans.

With mitered corners you can use the same plan with any thickness of materials. -

It looks to me as if you need a modified version of Chris Fullmer's Greeble plugin. I used it to do this example and the cuts are close to correct but not quite. The plugin sets the angle based on a percentage of the length of the original side. Works fine for a cube but for other shapes, not so much.

There's probably another plugin or a couple of plugins together that could do it. When I get a moment I'll do some hunting.

-

bjornkn:

Thank you very much for the explanation

I'll go with rule 2 since shearing could be an issue and it looks like it could make things simpler.

I'll go with rule 2 since shearing could be an issue and it looks like it could make things simpler.

Dave:

Thank you for the comment, i don't know that plugin but I'll have a look and if you find something then do let me know! I don't know how to tweak an existing ruby script so i hope there's something out there that could help me!

-

Out of curiosity, can the cutter cut a V-groove in paper? If so, do you even need to draw the V-groove? If the lines represent the centerline of the groove, maybe you don't need more to drive the cutter.

-

@dave r said:

Out of curiosity, can the cutter cut a V-groove in paper? If so, do you even need to draw the V-groove? If the lines represent the centerline of the groove, maybe you don't need more to drive the cutter.

The V grove isn't what I'm using for the models, it was an idea by bjornkn, but I don't have such a knife and I prefer to cut the parts as he describe in the corner trim example

-

I see. So you aren't actually folding the paper? You're just working from individual pieces and gluing them together?

-

Exactly, and the 'paper' is 2-4mm in thickness depending on the scale of the model and that's what's causing the problems

-

So what you need is a way to adjust the dimensions of some of the pieces to compensate for the thickness of the paper but not all the pieces need that adjustment.

-

@dave r said:

So what you need is a way to adjust the dimensions of some of the pieces to compensate for the thickness of the paper but not all the pieces need that adjustment.

Yes that's right

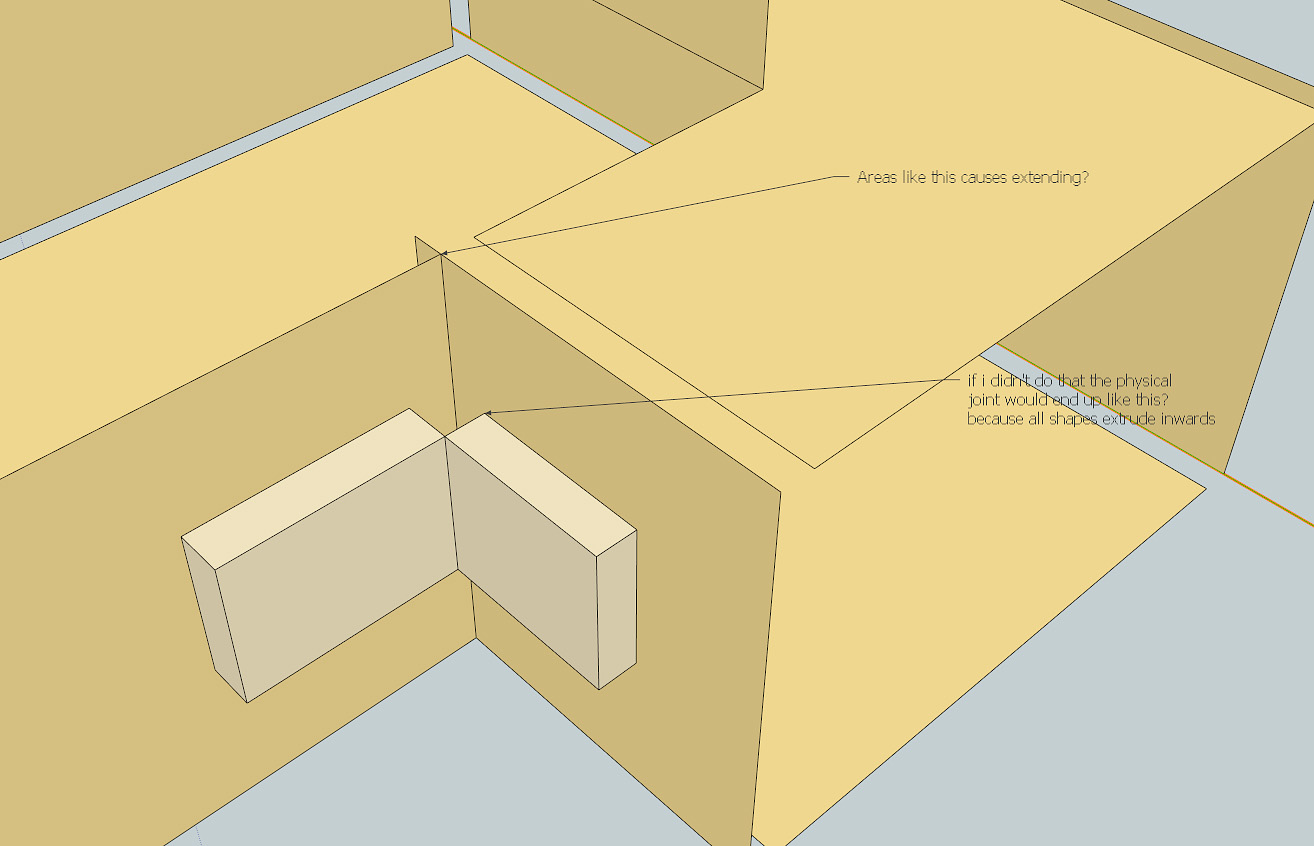

I would like to be able to model a building with non extruded walls (it leaves the model open for much faster changes) and then I would like to keep all outer dimensions the same as the 3D model for when I turn it into a physical model. This requires a lot of thinking and manually trimming some edges and so on as bjornkn explained it in his example (his walls are extruded but the same rules apply since I just work with invisible thickness)

I would like to be able to model a building with non extruded walls (it leaves the model open for much faster changes) and then I would like to keep all outer dimensions the same as the 3D model for when I turn it into a physical model. This requires a lot of thinking and manually trimming some edges and so on as bjornkn explained it in his example (his walls are extruded but the same rules apply since I just work with invisible thickness)I hope it makes sense

-

Well, my example wasn't the SU model, but a model of the finished cardboard version, with exaggerated thickness

-

@bjornkn said:

Well, my example wasn't the SU model, but a model of the finished cardboard version, with exaggerated thickness

yes i know, but it would appear similar in SU with extrudes walls right

-

No. You just make the normal solid model as usual, with no thickness.

Then after you have it unfolded you do the trimming where needed. -

A little free thinking. Very little.

First, would a paper model be made of more than one thickness of paper?

Second, would there be a way to generalize the parts that need to be reduced to compensate for the thickness of the joining parts? For example, could you say that all vertical faces need to be shortened by the thickness of the top? And then all faces parallel to the green axis need to be reduced in width by the thickness of the parts parallel to the red axis. That's very simplistic and obviously doesn't account for walls that aren't parallel to an axis.I think before you can ask for a plugin you have to determine rules for how the adjustments are done. Maybe it can't be simplified like that, though.

-

On a related note, I used to have this problem all the time. One big time saver that I found was to shorten the unfolding process. There are a number of very good plugins on this site for unfolding, but what I liked to use is called Pepakura, http://www.tamasoft.co.jp/pepakura-en/. It unfolds your model and tries to keep as many edges together. You can add labels to the edges, too. Then I would edit it in Autocad and make adjustments for thickness. Also, if these are primarily exterior models, you can use single-ply museum board (essentially a thick paper), score it (with a laser cutter) and fold it. Pepakura can add tabs to loose edges so you'd have something to glue.

Just a thought.

EDIT: I just found the Waybe plugin for SketchUp. The full version is $80USD for the educational license. More expensive than Pepakura, but right in SketchUp. Then there is the Flattery plugin, which is free. Still won't help you with the thickness issue, but may save time before so you have more to adjust for thickness.

-

Dave:

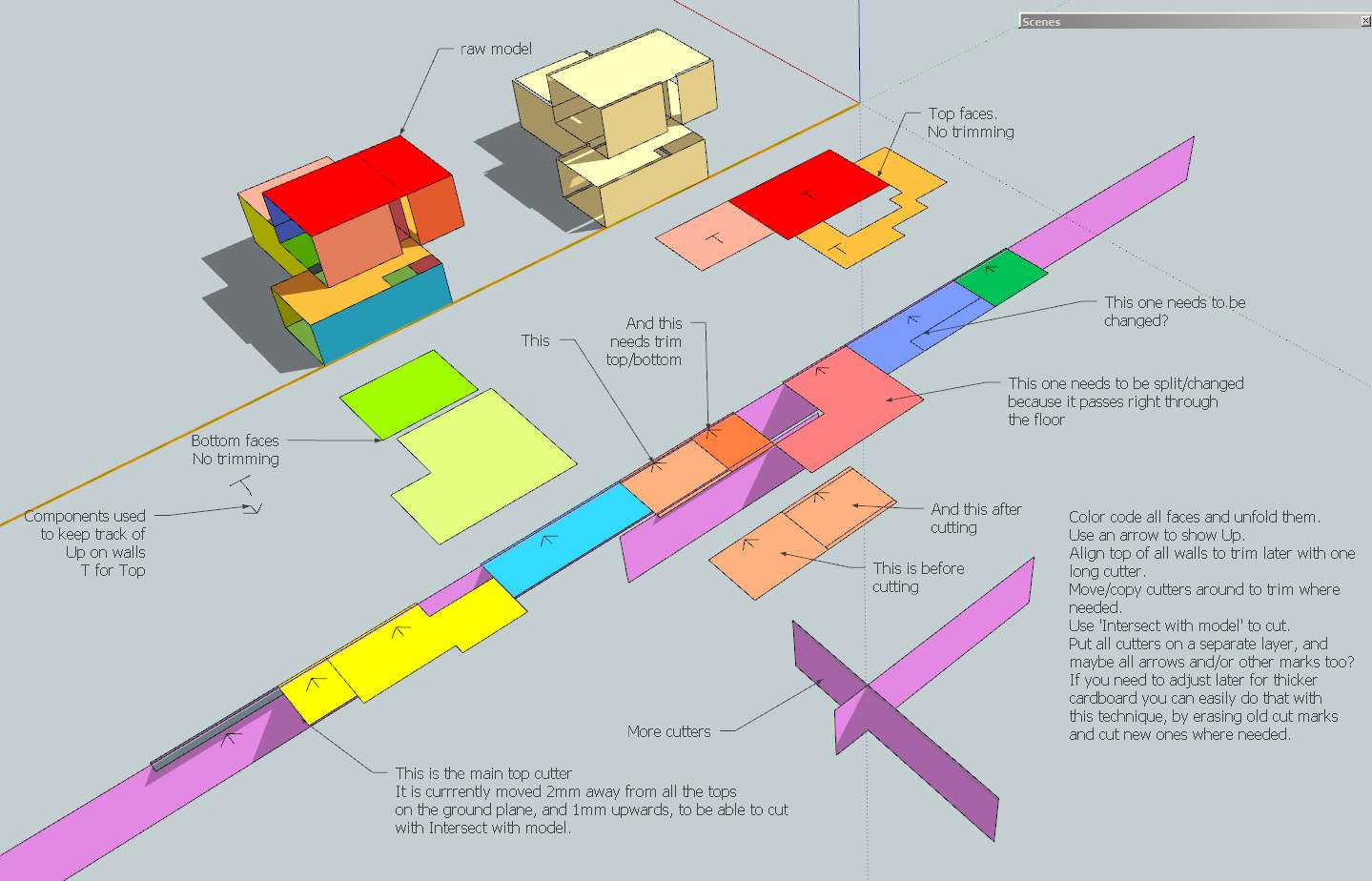

I have attached a file that shows the adjustments necessary, the next step in my test file would be to unfold the 'adjusted' model with Flattery or similar script.

I don't know how is possible via ruby, but if that's possible via a plugin it would be great The model is adjusted for 2mm material.

The model is adjusted for 2mm material.ledisnomad: thank you for the input

I'll check the plugins you mention!!

I'll check the plugins you mention!!

"Then I would edit it in Autocad and make adjustments for thickness" I don't understand how that's possible, I found it a bit hard to adjust the model within sketchup but if i only had the 2d shapes in AC I would be totally lost :S you must be very good

The models are not only exterior models, they need to look perfect both in and out. My goal is to have a working method that would be 99% precise then I could start making models in other materials even metal because I wouldn't have to tweak it with a knife anymore

Thanks again to all of you!

-

@unknownuser said:

I don't understand how that's possible, I found it a bit hard to adjust the model within sketchup but if i only had the 2d shapes in AC I would be totally lost

Essentially all you are doing is "cutting off" the thickness from one piece, right? So if you know which edges attach to each other (a simple intersection, two walls for example, will be a pair), then you need to cut off 2mm (or whatever) from one side of the pair. If you use a plugin that labels matching edges, then you just offset/stretch/whatever the edge in each pair.

Of course nothing is that simple with a real project, so there will be roofs, floors, complex intersections, etc. But with the labels, things go pretty quickly with just a little practice.

-

-

bjornkn,

wow! thank you for taking the time to make such a detailed explanation!!

In my example I trim the top and bottom due to some other design issues but I get the point, but because I can't add any volume on the outside (all external measurements needs to stay 100% the same, then there's shapes that needs to be extended instead of trimmed, isn't that true? I have attached a picture. These small unforseen adjustments seems to be quite confusing :S

Do you use the flattery script to move all faces to the horizontal position, or do you do it manually?

Thanks again!

Advertisement