@d12dozr said:

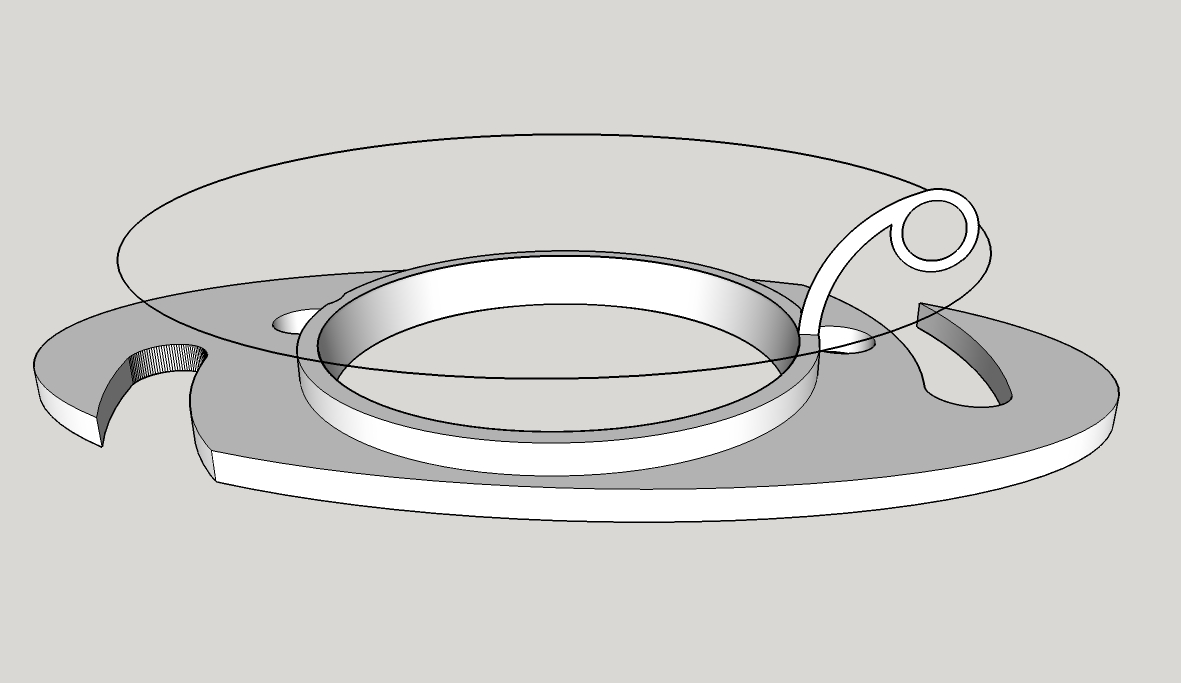

Teig, two of the holes on the bottom are causing the problem, as pointed out in the following image.

[attachment=1:1wvyo62i]<!-- ia1 -->Capture.JPG<!-- ia1 -->[/attachment:1wvyo62i]

If you pull those 2 faces down a fraction of a mm and clean up the resulting internal faces, the model becomes solid.

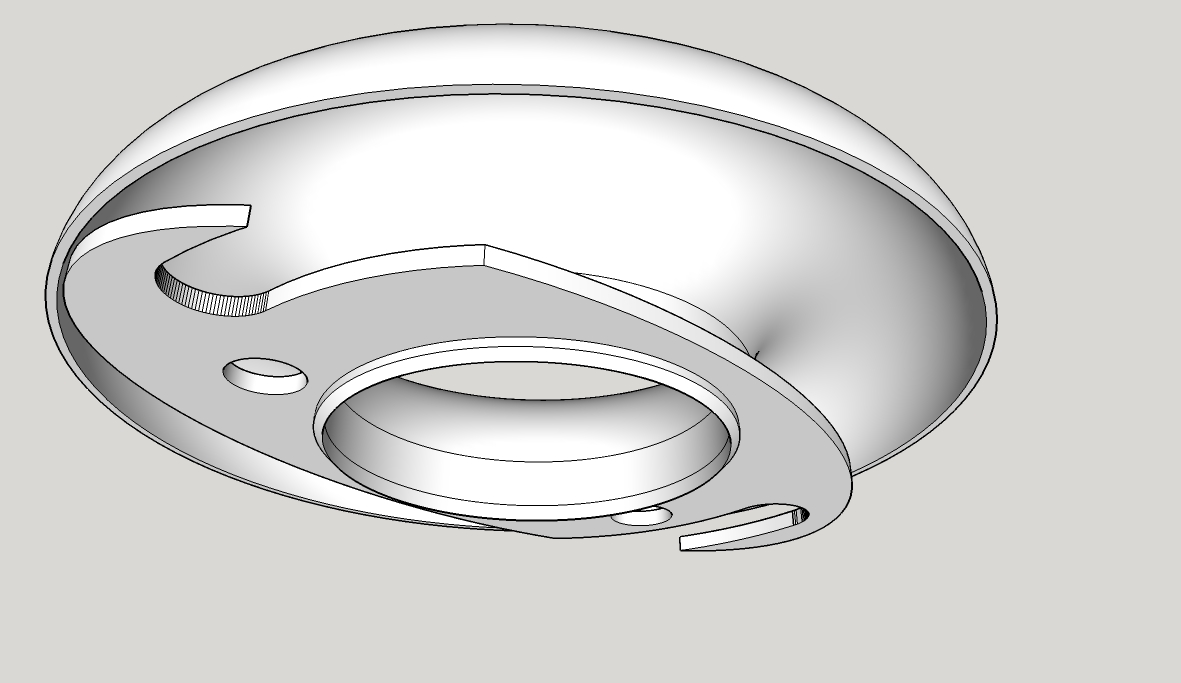

Thank you very much once again d12dozr.  I pulled those faces down by 0.03mm, grouped it again, it reported back as a group sigh . I exploded it again, pushed the faces 'up', it wanted to snap to .04mm so I left it, did the other one. Drumroll It reported back as solid!!!

I pulled those faces down by 0.03mm, grouped it again, it reported back as a group sigh . I exploded it again, pushed the faces 'up', it wanted to snap to .04mm so I left it, did the other one. Drumroll It reported back as solid!!!

@d12dozr said:

@teig said:

So I don't need the supporting material if I go to a commercial printer? I'm starting to think that it might be the better option.

For a part with this complexity, you'd be better off. Something like Shapeways Strong and Flexible (S&F) plastic should work well. BTW, since this is a part for a carburetor, how hot would the piece get? Shapeways S&F melting point is ~180C.

ABS from a desktop printer melts at ~200C.

You pre-empted my next question

Either of those two plastics should be fine then, I can't imagine it getting over 180C even in traffic on a summer's day? The venturi will constantly pulling cool air over it as well.

[attachment=0:1wvyo62i]<!-- ia0 -->Sub Stack11v6solidFinal.skp<!-- ia0 -->[/attachment:1wvyo62i]

Sub Stack11v6solidFinal.skp

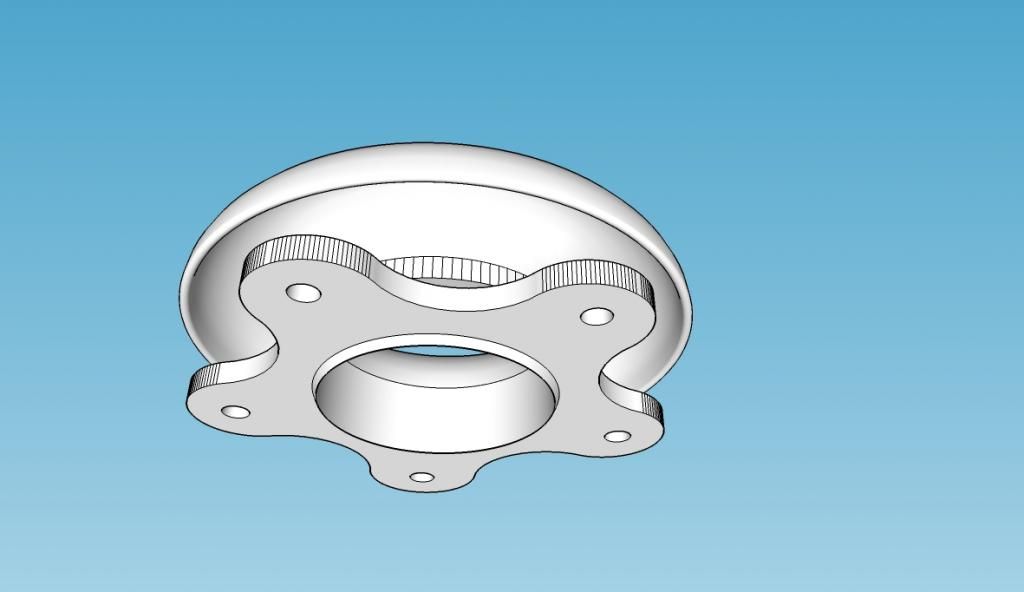

I've scaled it all up, I couldn't figure out how to separate the two parts so ran the Follow Me, it worked

I've scaled it all up, I couldn't figure out how to separate the two parts so ran the Follow Me, it worked