Good information in the couple days I've been out.

As for not having a TV, trust me when I say I agree. I haven't watched TV on my own (without her begging me to "spend time with her" after work or something in years.

However, I won't complain about a big screen I can hook my PS3/Xbox360 up to. Currently I use my two computer monitors for them.

As for the base of this thing, it will be your typical TV stand. 18-20 inches deep and probably 50+ inches wide. Her current tv stand is a dresser that is 18x54x30 ish. Has enough room for her 32", and the various video devies stacked up next to it. That fills up 100% of the width of it.

A typical 55 inch (the biggest she said she would ever buy, and I agree) is about 52 inches wide I think. But having the bottom 30 inches up is way too high for a screen that big.

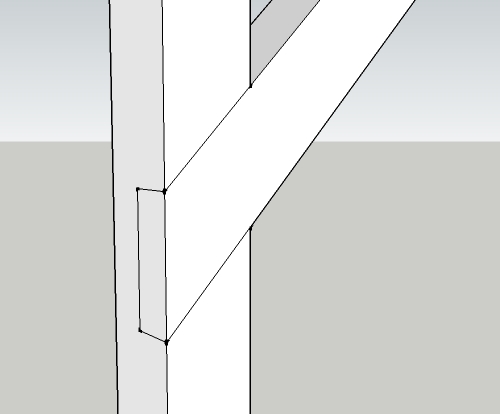

So what I was thinking was something about 20-24 inches high, with a post to mount the TV on just because it looks better like that.

Something with similar dimensions to this:

Except it won't be 600 dollars... Those things are pretty darn stable, the only way it can fall is backwards.

I might actually look into having something fabricated out of steel. I don't know how to weld, but my uncle does and has the tools to do it. We also know companies that can cut the pieces for low cost to me. That might actually be easier to do.