Thread maker plug in

-

Hi Does anyone know of a plugin to make threads for OSMac?

The ones I found have come up with a pop up saying its not compatible with my system

Thanks Dean -

May be this one:

https://sketchucation.com/forums/viewtopic.php?f=15&t=15784#p240238 -

What do you need from these threads? Do you just need to represent threads are are you planning to 3D print them? Or maybe something else?

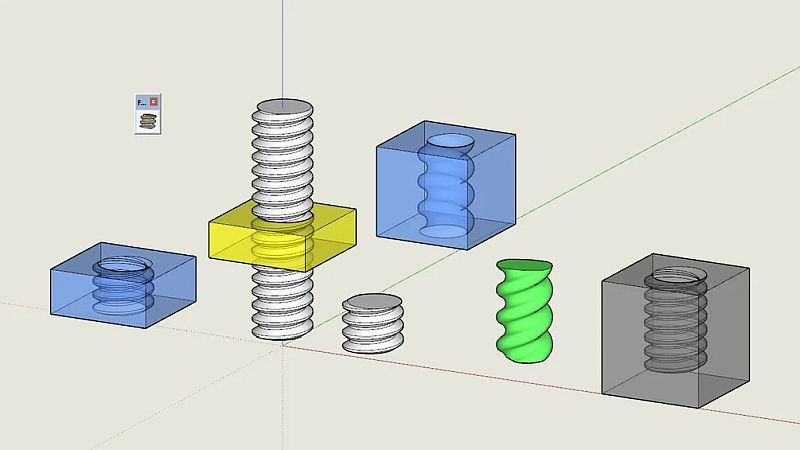

If I need threads that match existing standards, I find it better to draw the correct profile and extrude it along a helical path. Here are some fairly recent examples.

-

hi Yeah I need it for 3d printing

-

nice work by the way

-

Thank you.

If you really must have an extension to make threads, you might look at Bolt Maker or Draw Whorl or EP Fasteners. I've used them all but as I said, I prefer to draw them differently.

-

Draw whorl , came with a pop up saying it was not compatible with my system, which I don't understand

-

I downloaded Bolt maker and it said unsigned, what does that mean , and what do I have to too?

-

What version of SketchUp? Your profile says you are using SU2016 Pro. It's marked as compatible with that.

The message will pop up with later versions but the extension does work in SU2019. It's not a real easy extension to use if you are trying to match standard machine threads but you can give it a go.

@unknownuser said:

I downloaded Bolt maker and it said unsigned, what does that mean , and what do I have to [do]?

Nothing. Just don't set the extension loading permissions too strict.

-

I just upgraded to pro 2019,$299, so i would have thought i would have been ok

-

You're OK by me.

-

Nothing. Just don't set the extension loading permissions too strict.

What do you mean by that?

EP fasteners is windows only I'm on Mac

-

@leggy said:

Nothing. Just don't set the extension loading permissions too strict.

What do you mean by that?

In the Extension Manager there's a gear icon for setting the loading policy. Leave it unrestricted and unsigned extensions will load just fine.

@leggy said:

EP fasteners is windows only I'm on Mac

That's not what your profile says.

Maybe you should fix that.

-

Thanks all changed

Do you have any tutorials to make your threads?

I mainly use metric

Thanks Dean -

Are you asking me? I don't have a current tutorial but it's not especially difficult. Work with units set to Meters and enter millimeters as meters. So for a 6mm screw, draw it as 6 meters. I use Curve Maker's Helix tool to create a helical path for the threads. For that 6mm screw and working in meters, the radius will be 3 meters and the height per turn will be 1 meter.

Then I draw the profile based on dimensions available just about anywhere. If you are modeling external threads you'll wind up drawing a face with a V-shaped notch in it. Draw this is place at the bottom of the helix. Then explode the group containing the helix.

Use Eneroth Upright Extruder to extrude the face up the helix.

As far as terminating the threads, it depends on what you need. Generally you'd draw a shape that matches the end of the screw and intersect that with the threads. For the bottom end of the external threads on this machinists jack I drew a cone and intersected it with the threads to get the chamfer. I used a similar cone on the top of the jack base for the internal threads. At the top of the screw I used a shape like you'd get with a round-nosed tool if you were turning that section of it on the lathe.

If you are 3D printing the model, make sure you clean it up. ThomThom's Solid Inspector2, and CleanUp3 can help as can TIG's Solid Solver.

-

Hi everyone,

I came across this thread while looking for discussions about generating threads in SketchUp. I know it's an old topic, but since it still gets a lot of views, I thought it might be useful to share a solution I've developed.

I’ve created a SketchUp plugin that automates the creation of threaded parts (bolts, nuts, internal threads, etc.). What makes it different is that it generates threads from a custom tooth profile, making it compatible with any type of thread, including multi-start threads.

Key Features:

Key Features:

Generate threaded rods, nuts, and internal threads in just a few clicks

Generate threaded rods, nuts, and internal threads in just a few clicks

Works with any thread profile – metric, imperial, trapezoidal, custom, etc.

Works with any thread profile – metric, imperial, trapezoidal, custom, etc.

Supports multi-start threads

Supports multi-start threadsHere’s a demo video showcasing how it works:

(The video is in French, but you can turn on YouTube subtitles and auto-translation.)

The plugin is available here:

- For the US users: https://fabcnc.gumroad.com/l/threads-filetages

- For the EU users: https://payhip.com/b/3j7ZF

If anyone here still needs an easy way to create threads in SketchUp, I’d love to hear your thoughts!

Renaud

Advertisement