3D Truss Models

-

IFC Classifications

I do not see IFC definitions of the truss components.

Will this be included in future versions of your plugin/extension?T2H BuildingStructureTools (by Tak2hata) is a good example of the implementation

of SketchUps IFC Classifications.Keep up the good work - I learn a little more about Trusses

with each or your new posts

-

I have not even looked into the IFC classifications yet. At this point I'm not even sure how to classify a truss with that classification system. I will look into that further.

-

Engineering Video:

The SketchUp model used in the video can be found here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

All of my sample models can be found here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

Valley Truss Set:

-

Hip Roof Framing:

SketchUp model used in the video can be found here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

Somewhat of an aside for other plugin developers or those using the API to create geometry:

I found with the compound miter cuts required for the hip roof framing that the easiest way to handle this was by doing a push pull to the correct length so that one side of the member was the correct length and then actually selecting an edge or vertex and moving this separately to create the angles required. In some cases this can get a little messy since it may introduce extra lines that bisect a plane but some simple logic can then delete those extraneous lines after the fact. I don't know if this is the most efficient method to do this sort of thing but after some testing I managed to get it work very reliably.

-

@pbacot said:

Watched the video. Good job! Quite clear and nice to watch.

My wife says I need to stop clearing my throat as I talk, other than that I think they mostly get the point across.

I'm still working on the manual, I've been busy the last few days so progress is slow. I've been looking around at other plugins the last few days and I'm beginning to wonder if my price point on this might be too high, most plugins are either free or a few dollars. Feedback in this regard is very much appreciated. I don't intend on making a lot of money on this project but I feel that I should at the same time be fairly compensated for the time and effort I have devoted.

-

You could always take one of the early versions of the plugin, with limited functionality (limited to say a certain type / types of trusses and possibly limited spans) and release it as a free version (probably without support, else you'll be inundated with queries), this is to wet people's appetite and to get them to use the plugin and buy into the paid version (with full and expanded functionality). You already have the full version going (rename to pro?), then there's a third tier (engineering version?) possibly as per the PM I've sent you.

-

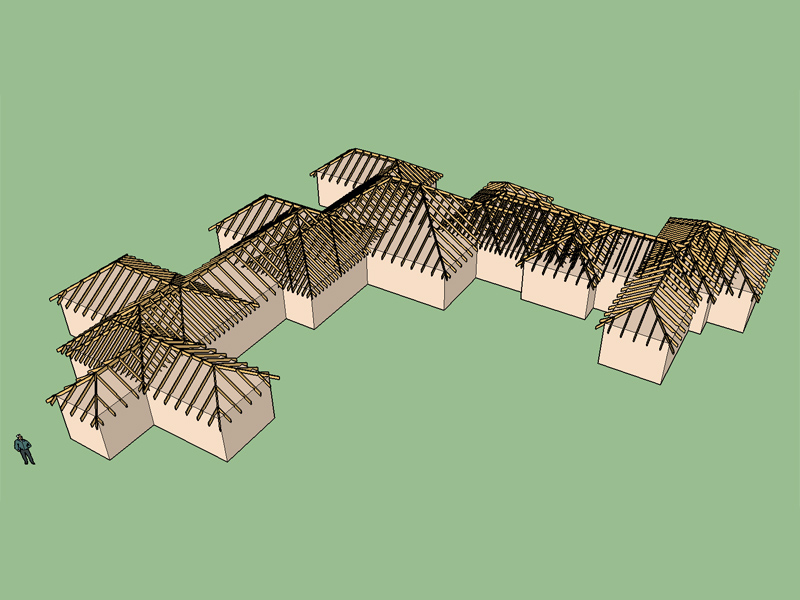

Testing the limits of the Medeek Truss Plugin with complex hip roofs. Note that the roof primitives have not been trimmed back. This is primarily a study to determine what additional programming would be required to generate this type of roof automatically:

This for me would be the holy grail of hip roof framing...

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

As you can see there is still a tremendous amount of work that can be done here. To that end I've started a KickStarter project which if successful would allow me to devote at least 4-5 months of my undivided attention on the programming of this plugin:

-

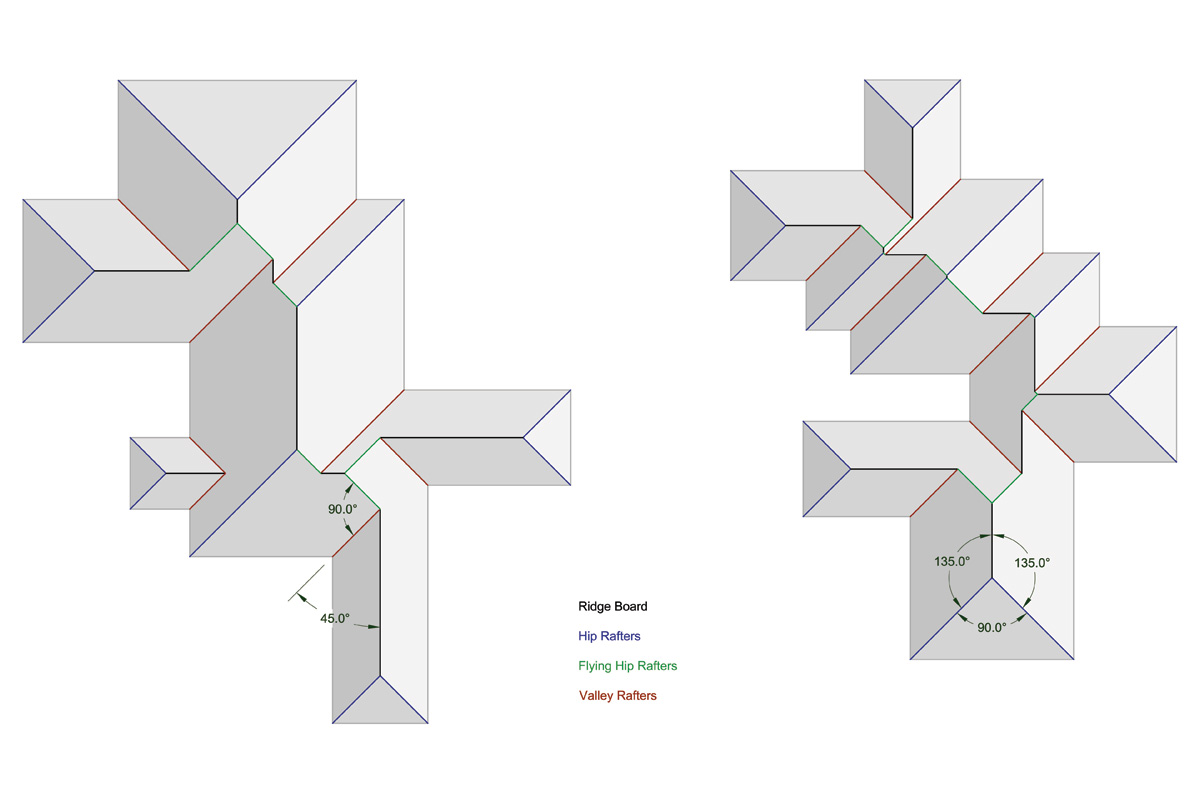

Pondering complex hip roofs this afternoon and considering the graphic below:

A few rules seem to emerge:

1.) An outside corner will always create a hip that is 45 deg. from each leg of the corner.

2.) An inside corner will likewise always create a valley 135 deg. from each leg of the corner.

3.) Where two hips or flying hips meet a ridge will extend 135 deg. from each hip.

4.) When two valleys meet at 90 deg. they will terminate and a ridge will extend at 45 deg. from each valley.

5.) With a building with walls only running north-south or east-west all ridge lines will always be north-south or east-west.

6.) Likewise all hips, valleys and flying hips will be oriented northwest, northeast, southwest, or southeast.

7.) When a valley meets a ridge, (they will always meet at 45 deg) a flying hip is generated that is 90 deg. from the valley and 135 deg from the ridge.

8.) When two valleys meet at 180 deg. from each other, the result will be either to flying hips perp. to the valleys or the degenerate case of 4 valleys and 4 ridges.

9.) When a valley and a hip meet each other at 180 deg. then two ridges that are 45 deg from the valley will be the result (typical L shaped roof).

10.) When 4 hips meet the result is a pyramid.There may be a few other degenerate cases I'm missing but I think that covers it.

-

Have you thought about multiple plate heights. Often when roofs are this complex, the house will also have multiple plate heights

-

Variation in plate heights, pitches, overhangs and even mixing hip and gable (half hip, dutch gable) further complicate the matter. To begin with I need a algorithm to generate the roof planes, then the framing just falls out from there. To create the roof planes I need a fairly robust straight skeleton implementation.

-

Version 1.2.6 - 01.18.2016

- Sill plate option (advanced) enabled for top and bottom bearing floor trusses.

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

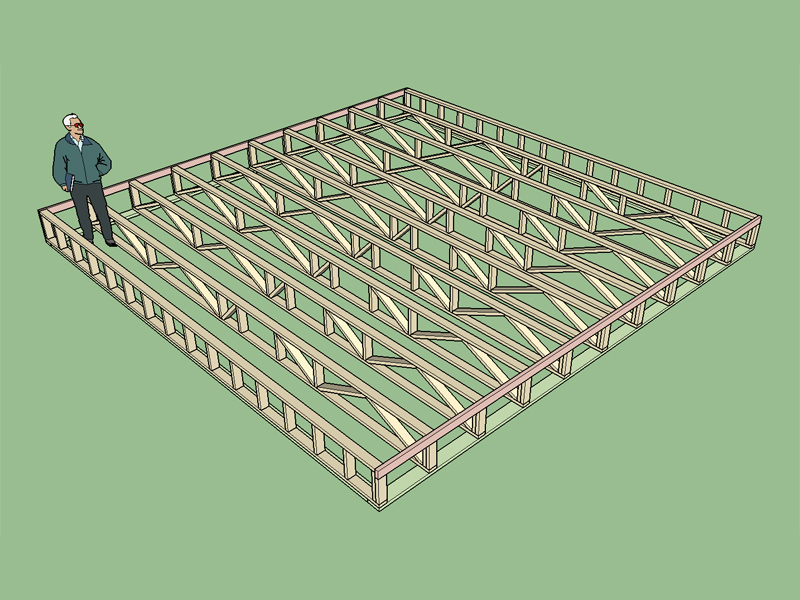

Work on the manual is progressing however for those interested the red colored boards in the image are called "ribbon boards". This is fairly typical for floor trusses. The notch purposely left in the truss to accommodate the ribbon board is called the ribbon cut or ribbon notch. Continuous ribbons provide stability for installed trusses, and also provide a solid nailing surface for the edge nailing of floor sheathing. This eliminates the need for larger and more expensive “rimboard” solutions required by dimensional lumber and other engineered wood products. 2x4 lumber is common, but any dimension of 2x lumber can be used for the ribbon board.

Similar to the complex hip roofs I need to program the floor truss/TJI module so that it can automatically frame out any non-rectangular floor plan. It seems like my goals keep getting more lofty and ambitious as I dig deeper into this, at some point I should reach the end of the rabbit hole.

-

Version 1.2.6 - 01.19.2016

- Added Solid Sawn Floor Joists (metric and imperial)

- Sill plate and Sheathing options (advanced) enabled for TJI and Solid Sawn floor joists.

-

@medeek said:

As you can see there is still a tremendous amount of work that can be done here. To that end I've started a KickStarter project which if successful would allow me to devote at least 4-5 months of my undivided attention on the programming of this plugin:

C'mon everyone ... let's help Nathaniel - I've put my seed money up for him, what about you? This is a pretty amazing plug-in that can only get better and more amazing!

(and, just for the record, I've already paid (pretty early on) for a permanent license!)

Thanks, Nathaniel, for undertaking this!

-

I just saw your pledge this morning, thank-you for the serious vote of confidence. I spent a few minutes and updated the KickStarter page to better reflect the current status of the plugin.

-

In a related note but slightly unrelated I've decided to take a small break from directly programming of the Truss Plugin and apply some effort to the integrated Truss Designer. I've had a number of requests by various parties and individuals to add in plywood gusset plates to the engineering of the Truss Designer, in lieu of standard metal plates (Mitek, Simpson, ITW etc...). This will allow for the design of site fabricated wood gusset connected trusses, something still found in remote agricultural locations. I'm thinking a couple weeks and I will have this programming task complete, at least for the common fink truss, and then put it out there to gauge the response. This new feature will be available from the Truss Plugin when fink trusses are analyzed.

-

Version 1.2.7 - 01.26.2016

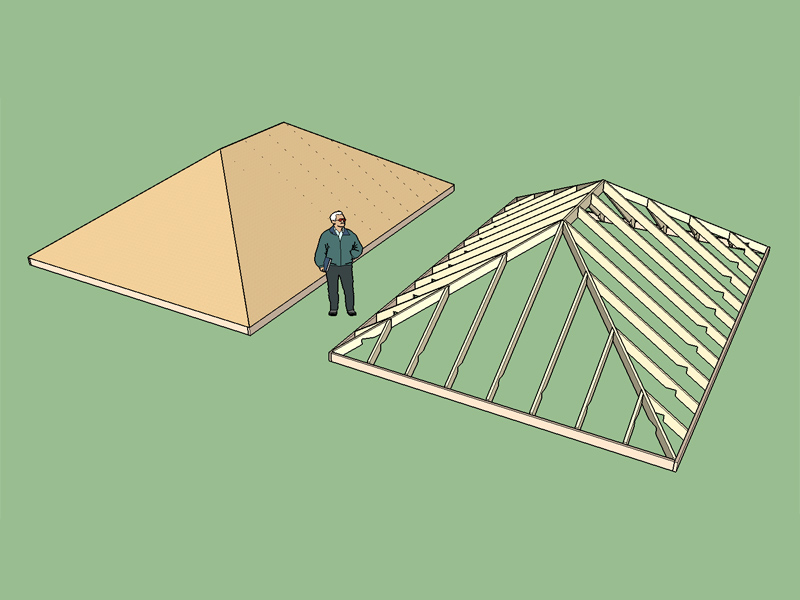

- Added advanced roof options for hip rafter roof (sheathing, fascia).

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

Couldn't resist adding in these options for hip roof since it was mostly there already from the gable roof module.

Adding in the roof sheathing was also an excellent check to make sure I had the roof planes correctly modeled. I'm glad to report that it all checks out.

At some point I also need to add more properties that tabulate, areas, lineal feet and weights. This information might be useful for engineering and material lists/estimating purposes.

Also note that the fascia boards are not angle at the corners, this is to more easily allow for one to manually push-pull these board to increase or decrease their length.

-

I've uploaded a test L-Shaped structure with a hip roof:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

I've created both hip roof primitives with the plugin, that was the easy part.

I then placed a valley rafter with its centerline (top) inline with both roof planes. I think I've got it right. What I am unsure of however is the best way to terminate the framing at the intersection of the valley, lower ridge and flying hip. Once I have a handle on how a carpenter would actually construct that junction I think I can proceed to start work on a secondary roof module for both hip and gable rafter roofs.

Advertisement