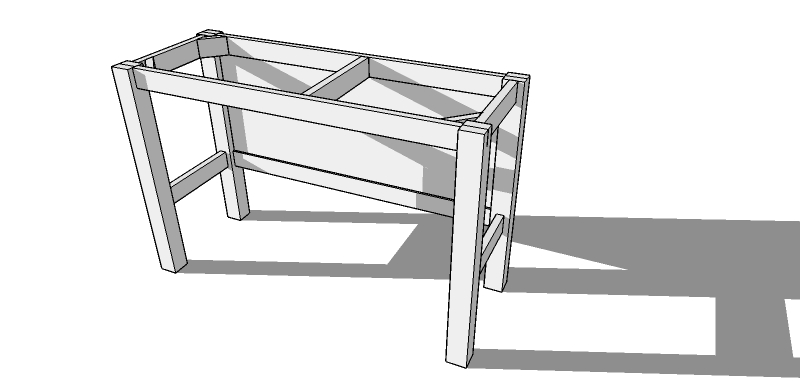

Mini woodworking challenge

-

Not so much a SU problem but a glue up assembly type brain problem which SU is great for helping to solve.

I have committed to my option, see model, for the first table anyway, I have 2 to make.

But I can't help thinking, there must be an easier/more efficient process to assemble.

Which means the least joints that have to be glued up and fitted in any one sub-assembly.

There are 54 dominos. My worst sub-ass is 10 doms to glu and fit in one go. They are bloody big tables too BTW.Weather is getting warmer here, so I have a glue open time of about 20mins, which is just enough time to ......

Bit silly, but I thought I'd throw it out there.

The su file is a working file, so please 'scuse the sloppy bits.

-

Barry, I don't see the huge number of dominoes. Am I missing something?

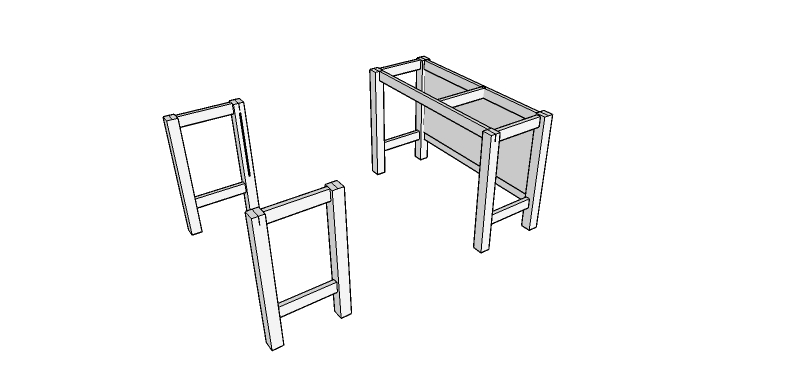

For glue up I would glue side assemblies together first and make sure they are square and flat.Then front and back rails (and the panel) can go together. If that center rail is getting dominoed in it'll need to be put in while doing the front and back rails but that shouldn't be too bad. I think I would make a dummy rail as a filler between the front legs to clamp at the bottom. This will make it easier to check that the bottom is square and adjust it if needed before the glue sets up.

The diagonal braces can be installed with screws.

You might get more open time if you come here and assemble it. It's -17°C as I type although my shop will be at around +7°C unless I turn up the heat.

-

Whoops, meant 28 per table.

Re: the squareness, don't mean to big note meself, but all the mating surfaces are as close to square and plumb as makes no difference and the beauty of dominos is that they give you a little bit of play for tweaking. I like the dummy rail tho, better safe than etc.I'm looking at your sequence but the last bit means assembling 8 joints at once...

-

Even though the faces of the parts are square, you'll want to check the frames for square by comparing diagonals and make adjustments as needed.

You could break down the assembly of the front and back rails to the legs. Glue in the center cross rail and clamp it up with a dummy rail in there to help you square them up. Then glue one end assembly followed by the other. You should have plenty of time.

-

LIke Dave, I'd do the end assemblies first, then the back assembly (separately), then add the front-to-back strut and front rail to the back assembly and finally attach the back+front rail to the ends.

Dominos are pretty precise, but I'd still test flat and square as Dave suggests to allow for any "user error". That can be a problem when attaching subassemblies since Dominos aren't all that tolerant of misalignment.

An assembly with a lot of Dominos that need to go home at the same time can be a real nuisance. It's tricky getting all of them into the slots at the same time, and frequently the fit is so tight that it won't push home without clamps. To ease things a bit, I do a couple of things. First, I make sure that the Dominos themselves are true thickness, either by drying them in a oven or by sanding/planing. Second, I shave off the little ridges on the edges, which makes them enter the slots more easily. Finally, I bevel the outward ends of the Dominos, which helps guide them into the slots.

-

It certainty looks like you can glue up in steps. Couple of tricks I have used over the years:

- I install glue blocks for clamping with brown paper bag material at inter face. You can get reasonable clamping pressure and they are easily knock off when you are done. Down side is glue can act as pore filler and give problem in finish. Waxilte can be used to help;

- I like to use hide glue because of its reparability and you can add a small amout of terp which decreases the vapor pressure and makes the set up time longer. I am in Colorado and in summer low humidity that helps a lots. If you check web site of your glue vendor they may have info, Fine Wood Working had an article some time ago.

BTW dry fitting helps ( glue up sequence) with speed of assembly with all clamps etc laid out.

The design is simple so #1 probably not required

-

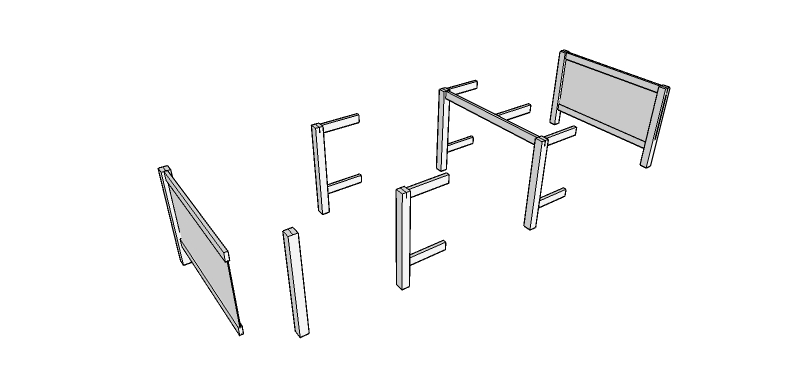

In case you havent looked at the model, here is my assembly sequence, followed by Daves suggestion if I understood his description.

As Sib says trying to fit too many doms at one time is a PITA, hence my current solution.

I do mess with the doms on occasion, but only when my joinery has been sloppy, in this case I am relying on the doms to line everything up perfectly. These are a for a commercial installation, a bar in a big hotel, so I am going for maximum strength.

-

[quote="baz"]In case you havent looked at the model, here is my assembly sequence, followed by Daves suggestion if I understood his description.

As Sib says trying to fit too many doms at one time is a PITA, hence my current solution.

I do mess with the doms on occasion, but only when my joinery has been sloppy, in this case I am relying on the doms to line everything up perfectly. These are a for a commercial installation, a bar in a big hotel, so I am going for maximum strength.[quote]

I have not open your model=> have not installed SU 2015 yet.

If item is long small error end up in large errors.

IMHO you need to assume doms cannot be installed " perfectly". I have a series of different length witness gauges I use with connectors from Veritas so do not have to use folding ruller to try and check square. Would use epoxy for strength and gap filling so sloppy doms would not be a problem and would have longer assembly time. Epoxy not repairable however: -

I don't have the capability of using dominos but my loose tenons are basically the same thing and have the same assembly questions. As other users have stated the secret is sub assemblies.

Typically I make the mortise tight on one part (this would be the part that has tenon when making a mortise and tenon joint) and on the other mortise I usually increase the slot width by 0.010 in each direction (0.02 total) Then I always glue the tenon or domino in one part (think the part that would have tenon) before starting a sub assembly. After gluing in the tenon then I do a dry assembly before attempting the final glue up.Also if you detailed the dominos I hope you used the K2WS_Tools plugin from the SketchUcation Plug In Store as that should simplify the process.

Keith

-

Sloppy or too tight joints can result in reduced strength. Bond line thickness should be controlled for max. strength. I use bond wires or beads to make that happen if I am concerned about getting max strength from joint. Ref https://www.dropbox.com/s/sg6rmadbzr4ahxb/fpl_gtr190.pdf?dl=0

-

Thanks Keith, will check out the plugin.

@ Mac, thanks for the Wood Handbook, great resource.

Advertisement