Adventures in 3D printing Sketchup models

-

I got to work with metal printing company for a few years.

My workflow is pretty much exactly how you guys do it; my Su models are often times 20 or more versions all 100', 200', 300' from origin.

I have used SU, Cheetah, and Zbrush all to great effect. Honestly, both of those softwares are inherently "better" than Su for making models for printing. Cheetah uses a modifier stack system which makes editing almost pleasant. Z brush is badass in many aspects (displacement painting with alpha masks, realtime multiple customizable symmetry operations, what?!) but it is a completely different flow than a 3D modeler.

That said, I still use SU the most, mostly because I am faster in it than anything else. Oftentimes, I make the base model in Su, then into Cheetah or Zbrush for sculpting, SubD, etc. And anything architectural was SU and then Z brush for surface sculpting (choosing a stone image and then using it to paint displacement onto a base mesh and then cranking the polygons to 200 mil for final blending and detailing sure is mind blowing and makes you hate SU for what it isn't and can't do.

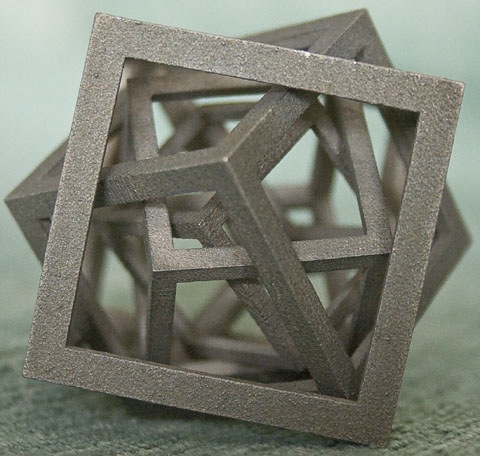

The stainless steel/bronze had a precision of .007". I settled on a 1/8"=10' printing vs modeling scale.

Here is a video I put together showing some of the renders I did during design development:

-

Chuck, that is some fantastic work

Were the models intended to be used as displays, or what was the end use?

I found a photo of your castle model on this blog post, listed under #4, ExOne 3D printers.

-

Thanks Dozer!

Exone hired me a few years ago to assist with developing presentation and retail models for marketing to various potential markets.

I developed some architectural models (us capitol, notre dame, castle, falling water, taj mahal), a bunch of cabinet and door hardware, and some islamic themed pieces for marketing to the middle east (I used 14-15 century islamic calligraphy as mu base vectors and then developed them into 3d models; pretty cool, I think, but it just didn't take off.

The metal printing is just, in my opinion, prohibitively expensive. The market for $200 cabinet knobs is pretty small, you know?

Exone went public in mid 2013 ; it's stock shot through the roof, and then it crashed badly last week due to poor quarterlies. Crashed so bad that I guess the entire 3d printing industry took a hit. Exone makes most of it's money, I think, from selling million dollar printers and they were hoping to support a merchandize line as ancilliatory use for their printers (might as well have the running all the time), but the cost just kept it from working out.

I did have a lot of fun playing with Zbrush, Cheetah, Illustrator, and SU developing these and I wish it had gone somewhere...

-

Yeah, I think you're right about cost. I see cost as a limiting factor even with professional plastic printing, and is one of the reasons 3D printing isn't used more frequently. When you do get a cheap print, say from a desktop printer, then the quality often isn't good enough to be taken seriously in a professional setting.

-

@solo said:

What I really want to know is the price if you have your own machine, I'm contemplating buying one, but do not know which one or what material yet.

If you are serious about buying your own machine these are the only two I've seen so far that have a reasonable price and professional level high resolution:

Form1

http://www.formlabs.com

(around $3000 USD) stereolithography "SLA"

300 micron feature size

25 micron layer thicknessRobox

http://robox.cel-uk.com/

(around $1400 or 849 Lire) Fused Deposition Modelling "FDM"

unspecified minimum feature size

20 Micron layer thicknessI suspect that the Form1 is probably the more precise and professional of the two as can be seen in their model examples, but where the Robox is filament fed it's probably much simpler and therefore easier to tinker with if necessary. Other printers I've seen haven't impressed me much, as far as the level of resolution, and that they don't have the specific features of valve control, self leveling, and/or good software.

-

@olishea said:

Sending off a model to i.materialise today. Let's see how it works out! I was up literally all night, when I sleep I'll be dreaming in quads!

Quick question. For price comparison I'm also sending model to shapeways. It has to be in STL format and I'm using meshlab to export. So I'm exporting as Collada, importing into meshlab and exporting STL.

Problem is, my model is coming out tiny, significantly smaller than it should be. Any ideas what I'm doing wrong?

[edit] found a STL plugin which works fine, still can't think why the other method didn't though, even though I specified model units.

You might want to try using Netfabb if you run into "strange" problems. I've often found that the older a file is in SU and the more I import objects into the model, the more probability of inconsistencies, which Netfabb Basic (free download) can fix. The interface is a little odd to get used to, but the results I've received from printing have been excellent.

-

@olishea said:

Sending off a model to i.materialise today. Let's see how it works out! I was up literally all night, when I sleep I'll be dreaming in quads!

Quick question. For price comparison I'm also sending model to shapeways. It has to be in STL format and I'm using meshlab to export. So I'm exporting as Collada, importing into meshlab and exporting STL.

Problem is, my model is coming out tiny, significantly smaller than it should be. Any ideas what I'm doing wrong?

[edit] found a STL plugin which works fine, still can't think why the other method didn't though, even though I specified model units.

When you upload the file on their site are you specifying metric or SAE? And then what units... good chance this is the problem.

-

Thanks for the reply....but did you see my edit?

I got it working by using a "Export to STL mm" plugin. Does exactly what it says on the tin.

When uploading I just specify mm and it works fine. I double checked the volume with my sketchup model and it's exactly the same. I have sent off for some CNC quotes too and the STL file I used was fine, preview looks good and the volume was the same. Just a shame CNC is crazy expensive!

-

@olishea said:

Thanks for the reply....but did you see my edit?

I got it working by using a "Export to STL mm" plugin. Does exactly what it says on the tin.

When uploading I just specify mm and it works fine. I double checked the volume with my sketchup model and it's exactly the same. I have sent off for some CNC quotes too and the STL file I used was fine, preview looks good and the volume was the same. Just a shame CNC is crazy expensive!

Oops, I didn't notice the edit.

For cnc try getting a quote from http://www.ponoko.com

They used to have good pricing, though I haven't worked with them for a couple of years. -

That's great thanks. Just putting some quotes together. Got some CNC quotes from UK but it was £421 for only a small item, less than 100 centimetre cubed.

CNC milled Aluminium is £421 whereas 3D printed Alumide is £84.73 although not directly comparable materials. Brass is also slightly cheaper when printed. Although I don't the think quality of either will touch CNC finish.

The beauty with 3D printing is that it makes you think outside the box to remove material and save money. Well that's the plan lol

-

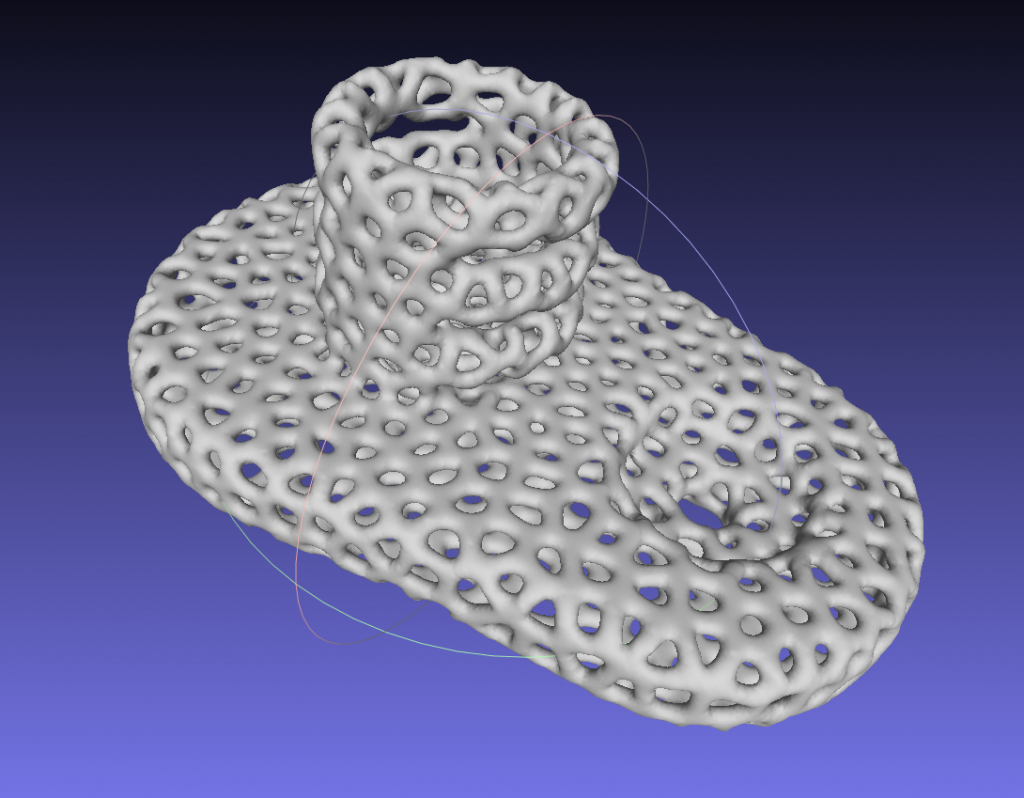

Would you need an internal support structure to print the attached models? Have you guys seen mesh mixer?

-

@olishea said:

That's great thanks. Just putting some quotes together. Got some CNC quotes from UK but it was £421 for only a small item, less than 100 centimetre cubed.

CNC milled Aluminium is £421 whereas 3D printed Alumide is £84.73 although not directly comparable materials. Brass is also slightly cheaper when printed. Although I don't the think quality of either will touch CNC finish.

The beauty with 3D printing is that it makes you think outside the box to remove material and save money. Well that's the plan lol

Oli, for the CNC'd parts, did you optimize the model for the process? ...or did you just get a quote for the same model that you used for 3D printing? I'm guessing the cost may be significantly less if you can save them repositioning time.

@olishea said:

Would you need an internal support structure to print the attached models?

Depends on how you're printing it. For any industrial process(like i.materialise or Shapeways uses), you don't need to think about supports. For printing on a small desktop machine, you would need additional supports.

I've only used meshmixer for converting files...pretty sweet what you're doing with it!

-

I used meshlab not mesh mixer to create those (with immense difficulty!)....but i was just wondering what you thought of mesh mixer. I saw some videos and was blown away, especially the hollowing out a shell feature.

@unknownuser said:

Oli, for the CNC'd parts, did you optimize the model for the process? ...or did you just get a quote for the same model that you used for 3D printing? I'm guessing the cost may be significantly less if you can save them repositioning time.

No I just sent them the stl file.

How do I go about this? Any links?

-

D'oh, I meant to type Meshlab, but meshmixer popped out

Meshlab is the one I use for converting files - works great for that. I've used Meshmixer for building support structures for my desktop printer, and for light editing of STL files. It handles sculpting pretty well. I haven't used it to full potential (I like my Sketchup

Meshlab is the one I use for converting files - works great for that. I've used Meshmixer for building support structures for my desktop printer, and for light editing of STL files. It handles sculpting pretty well. I haven't used it to full potential (I like my Sketchup  ), but has some very handy features beyond Skectchup's capability.

), but has some very handy features beyond Skectchup's capability.Re: optimizing for CNC, I would chat with the customer support at your CNC provider to see if there is any way that changing the geometry (without changing your design intent) would bring the cost down. This link briefly explains what I mean.

-

Thanks, they are cool shapes but incredibly difficult to model, each one takes a few hours.

Yeah meshlab looks awesome, will be a great tool for shelling things.

Yeah meshlab looks awesome, will be a great tool for shelling things.I'll chat with CNC company and see what they say. I doubt I can reduce the cost by 8 times!!

If they were £50 in aluminium, then maybe, but not £420! They didn't even give me a stainless quote because I know it will be crazy!

If they were £50 in aluminium, then maybe, but not £420! They didn't even give me a stainless quote because I know it will be crazy!  Oh and i know the above models can not be manufactured by CNC, before anyone tells me. They were just for 3D printing.

Oh and i know the above models can not be manufactured by CNC, before anyone tells me. They were just for 3D printing. -

Does anyone know how to export sketchup quads as actual quads when exporting obj

Or is there a file type that actually maintains quads?

Any quad mesh I make, whether it be in sketchup or wings turns out triangulated in meshlab. I've tried stl and obj import and they both have triangles. hmmmm.....

-

I'm stretching my memory here, but I know that some programs like Maya require modeling in quads (for clean results) BUT then when rendering it triangulates everything as the finished product, which leads me to think that triangulation is usually the case(?).

Maybe Autodesk 123D or Blender? Both are free and might be worth a shot. The 123D interface is similar to Autocad, which is old school and archaic and sucks in my opinion. But I'm just wondering if other programs have exporters that even though they export to the same file types still might keep things in quads once exported?

-

@olishea said:

I used meshlab not mesh mixer to create those (with immense difficulty!)....but i was just wondering what you thought of mesh mixer. I saw some videos and was blown away, especially the hollowing out a shell feature.

@unknownuser said:

Oli, for the CNC'd parts, did you optimize the model for the process? ...or did you just get a quote for the same model that you used for 3D printing? I'm guessing the cost may be significantly less if you can save them repositioning time.

No I just sent them the stl file.

How do I go about this? Any links?

There are CNC service sites (like Ponoko) that give details on how to optimize. Sorry I don't have links off hand, but do a search and I'm sure you will get a lot of results.

-

Thanks again. I don't want this thread to descend into troubleshooting, so I have posted my other questions in another thread. I got a reply off the CNC company about optimisation, gonna have a phone call with them tomorrow, but they are more than willing to help get this project off the ground and show how to reduce manufacture cost. Fingers crossed!

-

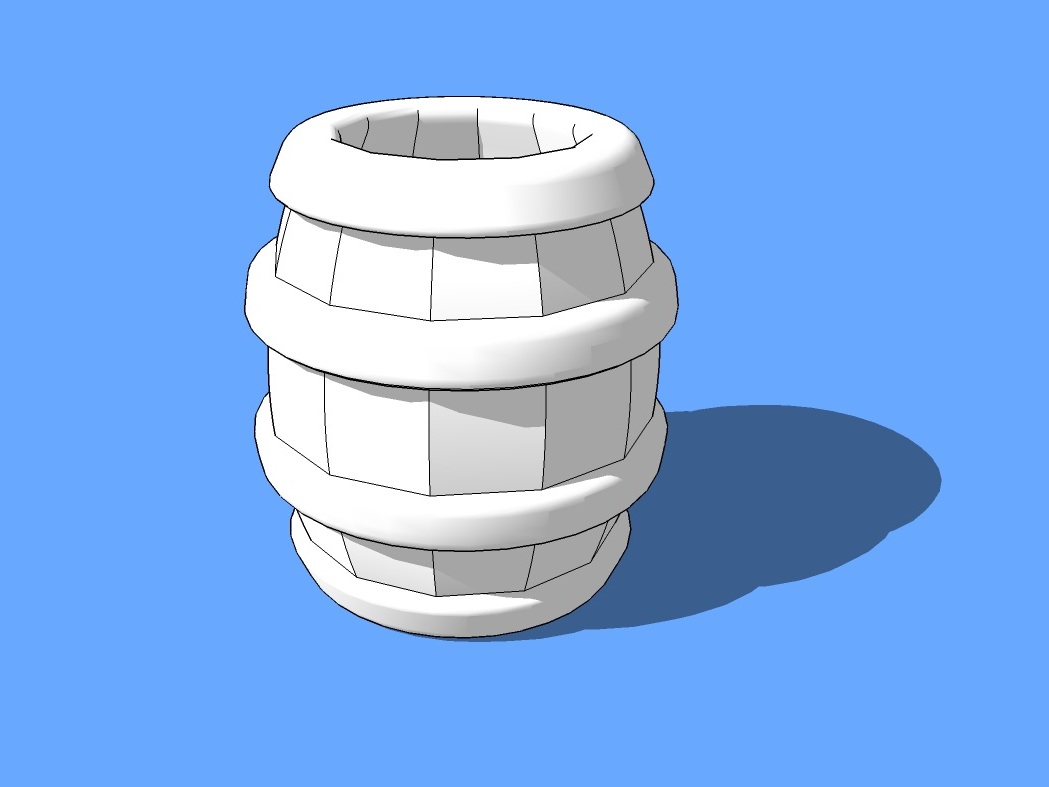

3D Printing is for Housewares!

These mini keg shotglasses are 3D printed in ceramic powder, then glazed and fired in a kiln.

This is a tea candle holder that I made as a gift for my sister in 2010. She still uses it almost every day! Printed in SLS nylon.

A lamp also made in SLS nylon. Its fun to pick up and play with, and also throws a neat pattern when lit.

Advertisement