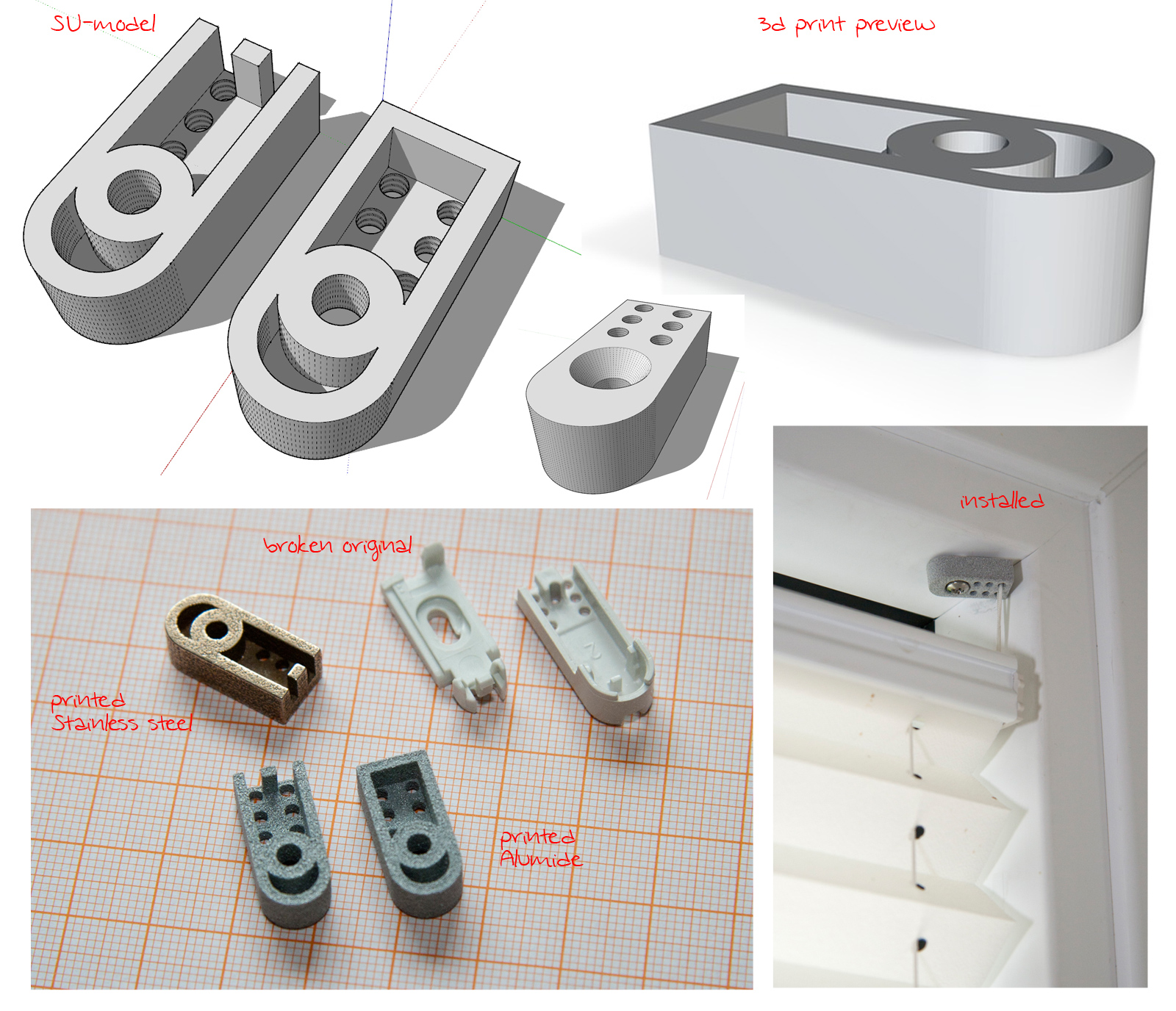

Adventures in 3D printing Sketchup models

-

A holder of our plissés was repeatedly broken, now it is replaced...

(Alumide: ca. 2 Euro, Steel ca. 8 Euro)

-

Solo, they offer discount for bulk orders too.

Thanks cotty, that really confirmed my suspicions. Guess I was stressing out over nothing! haha

-

What I really want to know is the price if you have your own machine, I'm contemplating buying one, but do not know which one or what material yet.

-

Pete, a part made on a home printer will cost roughly 1-5% of a professionally printed part, but you also have a lot more work involved and will get a much lower quality product.

This cabin was printed on a pro printer (Full Color Sandstone from Shapeways) for ~$150:

The same cabin printed in ABS plastic on my home printer for $2.25, not including the 3 failed prints - and the model doesn't look nearly as good.

If I knew how to operate the printer better, I could get better prints. I've had it for 6 months now, and have had 1 major problem where I had to tear apart the extruder to clean out jammed filament, and several smaller problems that took a few hours of troubleshooting to correct. Home 3D printers are NOT plug and play yet, and it really depends on your needs and skill level if you want to buy a printer.

An analogy of using a print service vs your own printer would be sending a Sketchup model to a professional render guy and getting back a nice polished render made with Thea, vs. trying to figure out how to use Kerkythea on your own with no prior knowledge of rendering.

-

Carsten, I bet you just look for broken components in your home so you can print a replacement! haha great work!

-

@olishea said:

Carsten, I bet you just look for broken components in your home so you can print a replacement! haha great work!

It's that obvious?

-

3D Printing is for - Jewelry!

These are pieces that I designed in Sketchup, printed via Shapeways and i.materilise, and sell to medical professionals online. The parts are not 3D printed directly, but rather a wax model is 3D printed, then placed in a plaster mold, and finished using lost-wax casting and hand polishing of the parts. The best thing is that the print services take care of all the work, sending my customers or myself the perfect finished part.

The pendants sell from $69 for the smallest silver one to $450 for the big gold pendant.

Sterling Silver

Solid 14K Gold

Solid 14K Gold

Solid 14K Gold

Sterling Silver

-

WOW!!! do you sell the chains too? They really don't look like they've been printed at all....I know they've been cast from a print but they are sooooo smooth!

-

I was seriously impressed with that big 14K gold pendant. Shapeways just started offering gold a month ago, and that was the first thing I ordered. They sent it out in that nice case (for free!), which is a really nice bonus. I had it in hand in just 7 business days!

I don't sell the chains, but have been thinking to add them. It's one more thing to have on hand and keep track of, but it may well be worth it.

-

@solo said:

What I really want to know is the price if you have your own machine, I'm contemplating buying one, but do not know which one or what material yet.

Pete, the best way to get a feel for these printers is to see one in person. There are local makerspaces in nearly all major cities that will let you come and take a look for free, or pay a monthly fee join to use the tools.

I looked up one in Dallas called the Dallas Makerspace: http://dallasmakerspace.org/

From their calendar, they have an Open House every Thursday night where you can pop in, get a tour, and ask questions. I have found the folks that frequent makerspaces are very receptive to questions and helping others get started in 3D printing and other useful skills. They can help you understand the different kinds of 3D printers and help you choose one that'll work for you.

For anyone else wanting to learn more about 3D printing, finding a makerspace (also called hackerspace) to see a printer in action and ask the regulars questions is an excellent way to get started. Here are a few ways to find groups with 3D printers:

-

Sending off a model to i.materialise today. Let's see how it works out! I was up literally all night, when I sleep I'll be dreaming in quads!

Quick question. For price comparison I'm also sending model to shapeways. It has to be in STL format and I'm using meshlab to export. So I'm exporting as Collada, importing into meshlab and exporting STL.

Problem is, my model is coming out tiny, significantly smaller than it should be. Any ideas what I'm doing wrong?

[edit] found a STL plugin which works fine, still can't think why the other method didn't though, even though I specified model units.

-

I'm guessing model units are getting mixed up in the process. Do you know about the STL exporter? If you use that, it's just one step and there shouldn't be any trouble! Protip - you can ZIP the file before uploading to speed the process.

-

That plugin didnt work for me on mac, version 8 sketchup. The created files contain no geometry and I've tried changing every option.

I used this one instead, worked first time. So easy!!

-

Nice find!

-

@cotty said:

...

[attachment=0:cghve6e2]<!-- ia0 -->vase_costs.jpg<!-- ia0 -->[/attachment:cghve6e2]btw if some one is planning to print custom lego parts, "coral red strong & flexible" is rather close to lego red

-

I got to work with metal printing company for a few years.

My workflow is pretty much exactly how you guys do it; my Su models are often times 20 or more versions all 100', 200', 300' from origin.

I have used SU, Cheetah, and Zbrush all to great effect. Honestly, both of those softwares are inherently "better" than Su for making models for printing. Cheetah uses a modifier stack system which makes editing almost pleasant. Z brush is badass in many aspects (displacement painting with alpha masks, realtime multiple customizable symmetry operations, what?!) but it is a completely different flow than a 3D modeler.

That said, I still use SU the most, mostly because I am faster in it than anything else. Oftentimes, I make the base model in Su, then into Cheetah or Zbrush for sculpting, SubD, etc. And anything architectural was SU and then Z brush for surface sculpting (choosing a stone image and then using it to paint displacement onto a base mesh and then cranking the polygons to 200 mil for final blending and detailing sure is mind blowing and makes you hate SU for what it isn't and can't do.

The stainless steel/bronze had a precision of .007". I settled on a 1/8"=10' printing vs modeling scale.

Here is a video I put together showing some of the renders I did during design development:

-

Chuck, that is some fantastic work

Were the models intended to be used as displays, or what was the end use?

I found a photo of your castle model on this blog post, listed under #4, ExOne 3D printers.

-

Thanks Dozer!

Exone hired me a few years ago to assist with developing presentation and retail models for marketing to various potential markets.

I developed some architectural models (us capitol, notre dame, castle, falling water, taj mahal), a bunch of cabinet and door hardware, and some islamic themed pieces for marketing to the middle east (I used 14-15 century islamic calligraphy as mu base vectors and then developed them into 3d models; pretty cool, I think, but it just didn't take off.

The metal printing is just, in my opinion, prohibitively expensive. The market for $200 cabinet knobs is pretty small, you know?

Exone went public in mid 2013 ; it's stock shot through the roof, and then it crashed badly last week due to poor quarterlies. Crashed so bad that I guess the entire 3d printing industry took a hit. Exone makes most of it's money, I think, from selling million dollar printers and they were hoping to support a merchandize line as ancilliatory use for their printers (might as well have the running all the time), but the cost just kept it from working out.

I did have a lot of fun playing with Zbrush, Cheetah, Illustrator, and SU developing these and I wish it had gone somewhere...

-

Yeah, I think you're right about cost. I see cost as a limiting factor even with professional plastic printing, and is one of the reasons 3D printing isn't used more frequently. When you do get a cheap print, say from a desktop printer, then the quality often isn't good enough to be taken seriously in a professional setting.

-

@solo said:

What I really want to know is the price if you have your own machine, I'm contemplating buying one, but do not know which one or what material yet.

If you are serious about buying your own machine these are the only two I've seen so far that have a reasonable price and professional level high resolution:

Form1

http://www.formlabs.com

(around $3000 USD) stereolithography "SLA"

300 micron feature size

25 micron layer thicknessRobox

http://robox.cel-uk.com/

(around $1400 or 849 Lire) Fused Deposition Modelling "FDM"

unspecified minimum feature size

20 Micron layer thicknessI suspect that the Form1 is probably the more precise and professional of the two as can be seen in their model examples, but where the Robox is filament fed it's probably much simpler and therefore easier to tinker with if necessary. Other printers I've seen haven't impressed me much, as far as the level of resolution, and that they don't have the specific features of valve control, self leveling, and/or good software.

Advertisement