Circle and arc segment amount for 3D printing

-

The segment length would be dependent upon not only the number of segments but also the radius of the arc. A small radius might not require as many segments as a large radius. You can see that when you are drawing in SketchUp, too.

-

@dave r said:

The segment length would be dependent upon not only the number of segments but also the radius of the arc. A small radius might not require as many segments as a large radius. You can see that when you are drawing in SketchUp, too.

So what I'm getting from both comments is that there is no set or standard number for achieving a good smooth surface when outputted to a 3D printer. Is that based on your actual experience with 3D printing? I'm really trying to find a set number so I can just model within my projects, and not have to reset arc and circle segments for every little change in size.

Has anyone experienced any kind of trial and error with outputting to 3D printing to find a happy medium for detail, but not have any post printing extra work to do to make a circle look smooth?

Thanks for your input guys.

-

@jaxcoffee said:

So what I'm getting from both comments is that there is no set or standard number for achieving a good smooth surface when outputted to a 3D printer.

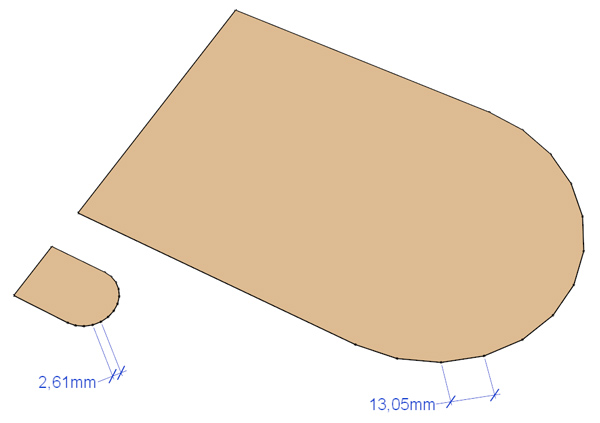

Yes, have a look at this shapes with an 12 segment arc: one maybe printed smooth but the other not because of the different segment length...

And there are many different materials you can use with 3d printing, every one with a different smallest geometry, ... so this influences the needed segment length too.

-

@cotty said:

@jaxcoffee said:

So what I'm getting from both comments is that there is no set or standard number for achieving a good smooth surface when outputted to a 3D printer.

Yes, have a look at this shapes with an 12 segment arc: one maybe printed smooth but the other not because of the different segment length...

And there are many different materials you can use with 3d printing, every one with a different smallest geometry, ... so this influences the needed segment length too.I understand what you are saying Cotty by segment length, but that length is determined by the number of segments in a given arch/circle. Which is how it is setup in SketchUp.

So it appears I may need to ask the question of those who would be doing the output. Also it seems that if one is modeling a project, one could determine by the largest circle/arch what is the smoothest output for it, and just let it be what is used by the smaller circles also.

So can I assume that having too many segments in a smaller circle would not be a negative issue with 3D printing?

-

@jaxcoffee said:

So can I assume that having too many segments in a smaller circle would not be a negative issue with 3D printing?

I would agree.

-

This is quite interesting and right along the same lines as we are talking about.

I just had the president of a 3D output company called Build Parts tell me that 99.9% of the files they get from objects modeled with SketchUp don't work.

Can someone elaborate on why that may be true? I don't want to have to learn Solidworks, which seems to be the standard for 3D print output companies.

Has anyone really looked into what needs to be improved within SketchUp to bring things up to speed for this technology?

-

Most of the modellers don't care about solid object, maybe he is referring to "bad" modeled warehouse models?

For me 100% percent of my printed parts were printable on the first try. -

I thought that items did not have to be solid objects? Am I misunderstanding your comment? Modeling in solids means the purchase of the pro version if I understand that correctly. I'm really just trying to learn how to model the best for 3D output, so getting these answers are important to developing a workflow for our project.

And of course if we have to be making a purchase of the Pro version of SketchUp, I would like to know before getting to deep into our work. Thanks

-

You don't need the PRO version to make solid objects!

A simple rule for solid objects (groups or components): every edge touchs exactly 2 faces (no groups/components inside) -

@cotty said:

You don't need the PRO version to make solid objects!

A simple rule for solid objects (groups or components): every edge touchs exactly 2 faces (no groups/components inside)Here are some more hints by Aidan Chorpa: http://www.dummies.com/how-to/content/understanding-solid-objects-in-google-sketchup-8.html

(Hint: making solid objects deson't need solid tools, which are 'editors' in the PRO version)

-

@jaxcoffee said:

I just had the president of a 3D output company called Build Parts tell me that 99.9% of the files they get from objects modeled with SketchUp don't work.

Can someone elaborate on why that may be true? I don't want to have to learn Solidworks, which seems to be the standard for 3D print output companies.

Carsten is quite right - most modelers don't care, or more importantly don't know how to make solid objects.

Your reaction is a perfect example - you are a good modeler and as long as you have been using Sketchup to make models, you didn't know what solid models are. I think this is a result of poor marketing and inadequate education from the Sketchup team.

Part of the problem also lies with Sketchup itself, where punching a circle in a face can turn a seemingly perfect model into a mess of intersecting faces and 'bad edges'.

-

FYI; some interesting info https://www.google.com/search?sourceid=navclient&ie=UTF-8&rlz=1T4NDKB_enUS554US555&q=jay+leno+3d+printing

-

And this http://www.stratasys.com/~/media/Main/Secure/White%20Papers/Rebranded/SSYS-WP-AccuracyMyth-03-13.ashx

copy and paste link -

Mac, I couldn't get your link to work, but changing the filetype to PDF worked...like this (PDF download): http://www.stratasys.com/~/media/Main/Secure/White%20Papers/Rebranded/SSYS-WP-AccuracyMyth-03-13.pdf

Advertisement