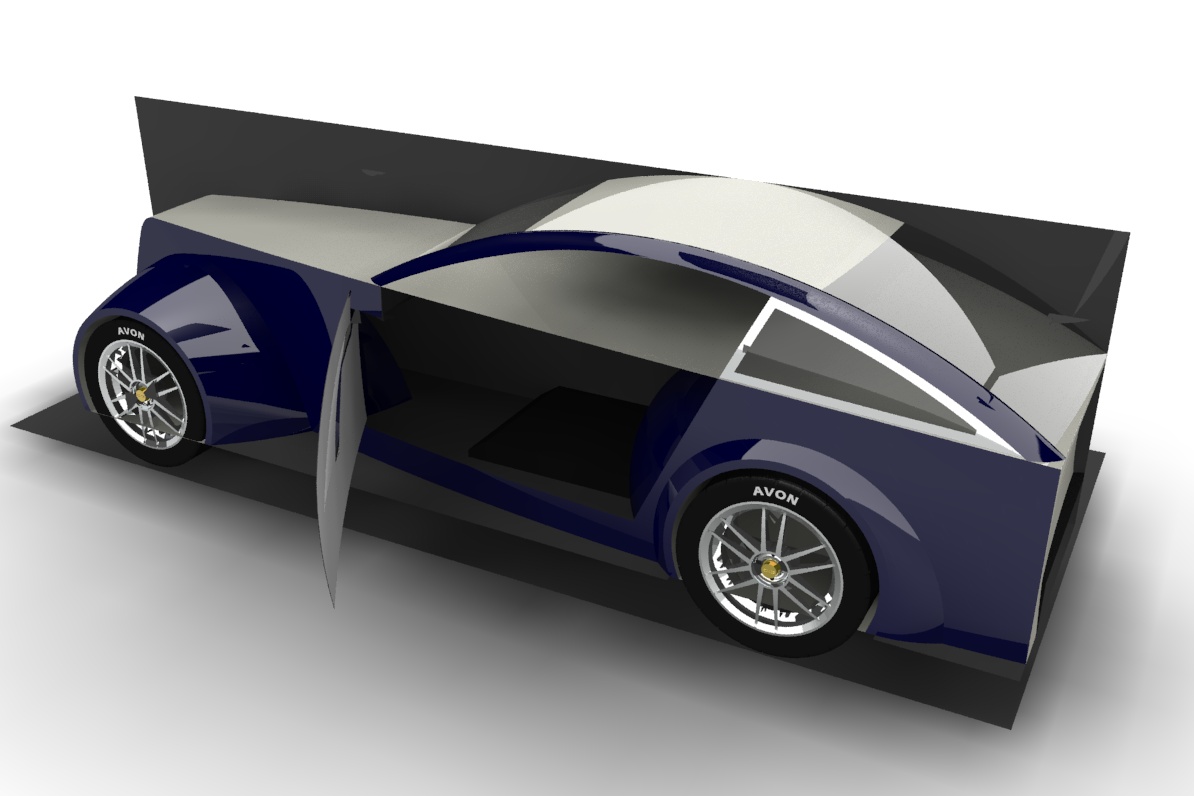

Another car ish, a bit........

-

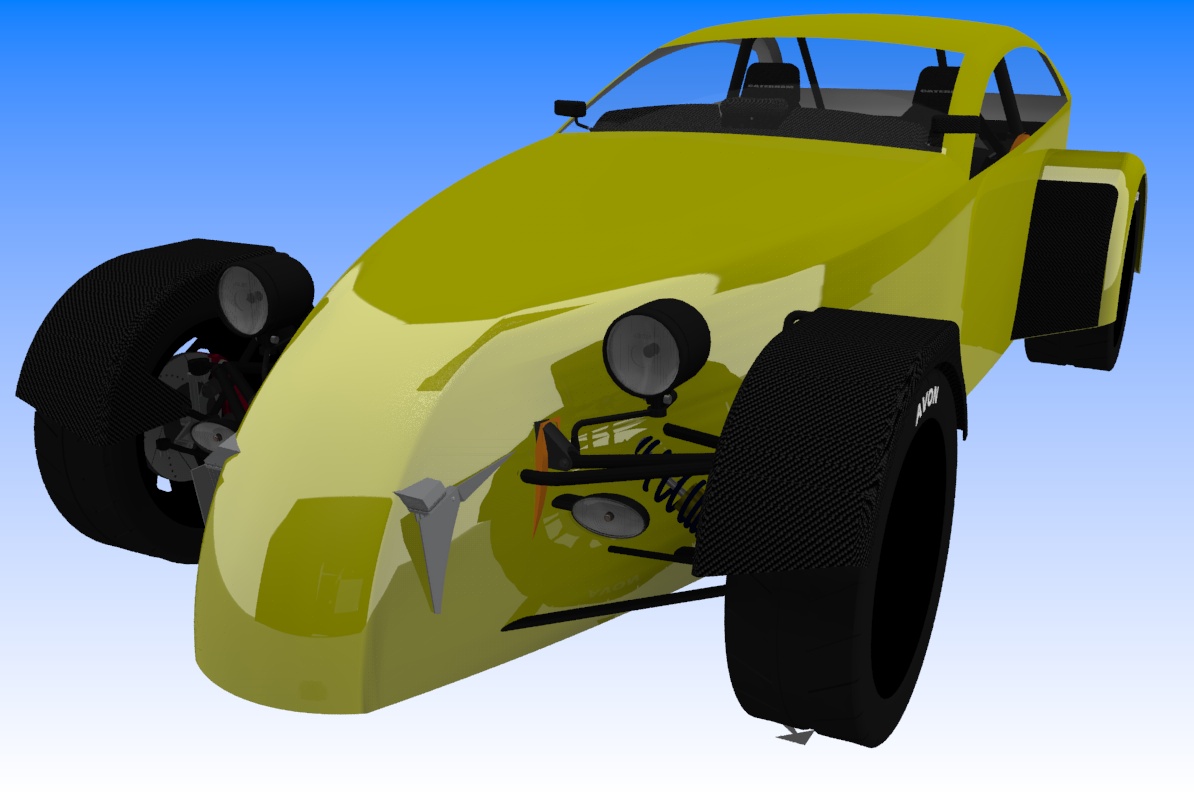

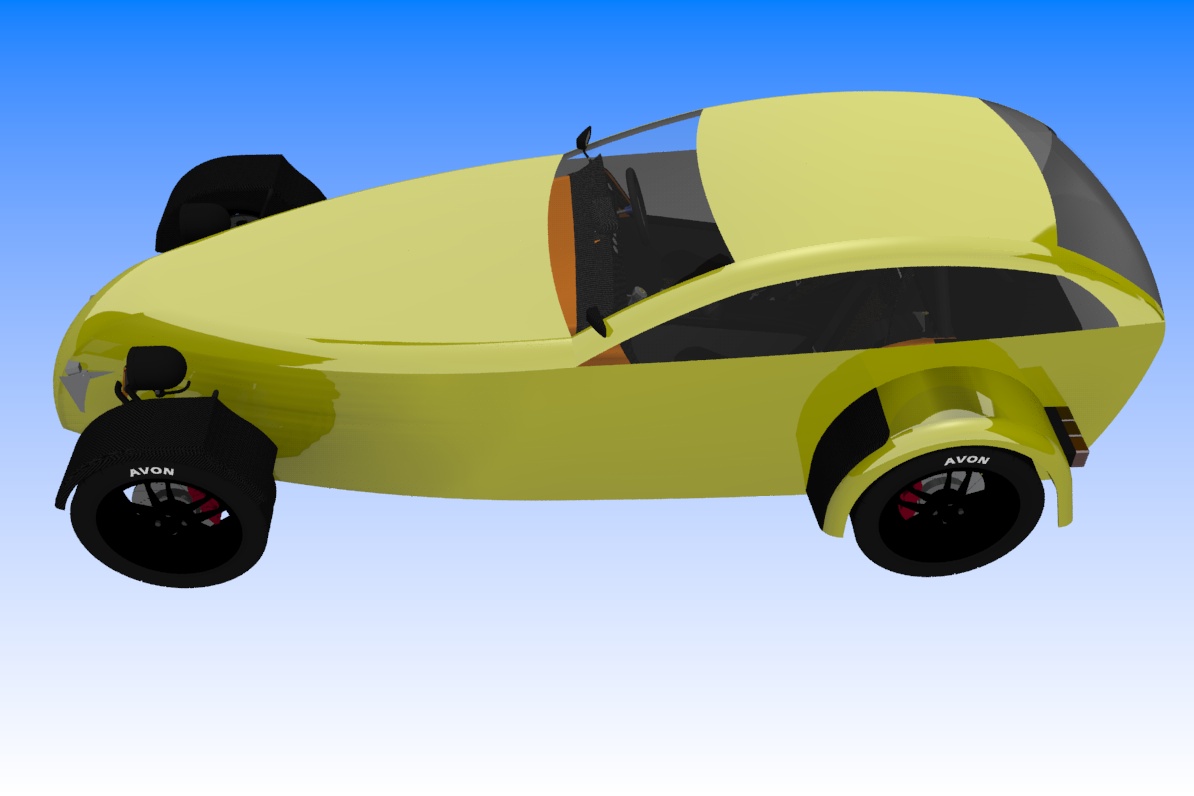

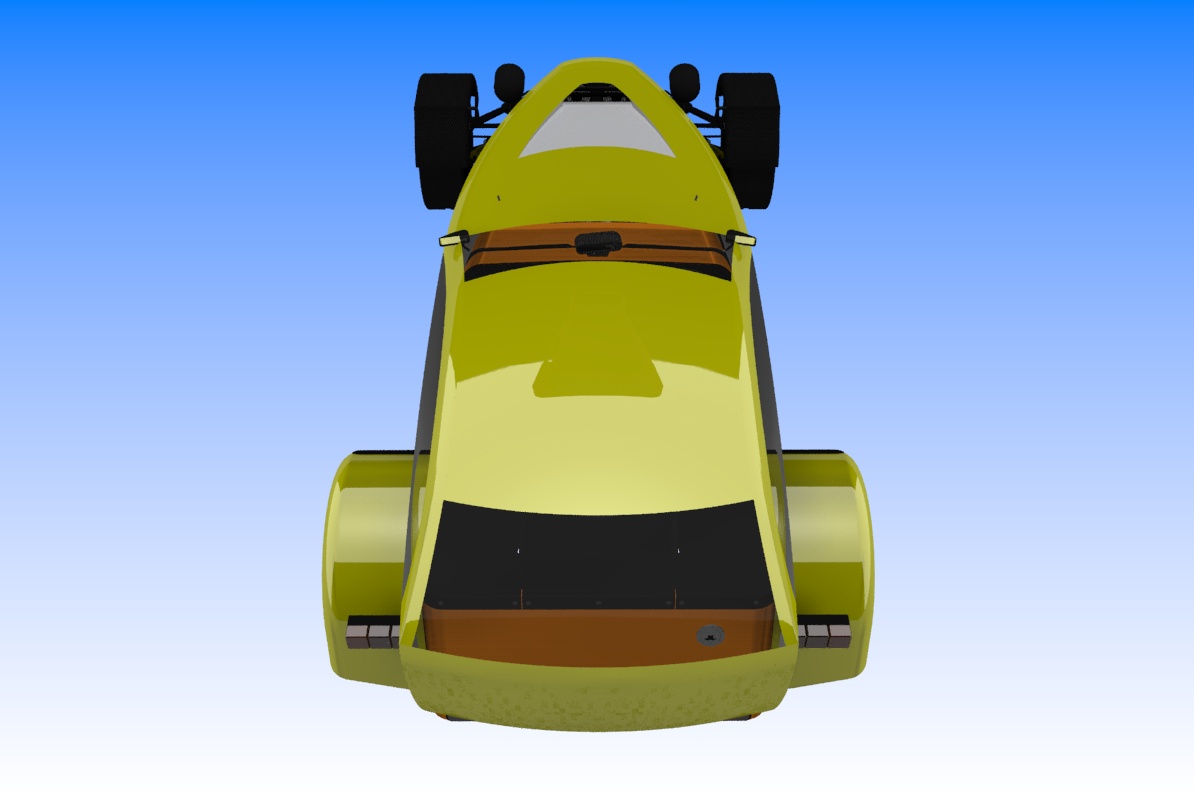

Trying to get my brain around styling and building a car of my design. I am quite interested in a cross between the morgan aero and the caterham 7 with a little influence from classic american rods. No not Stewart, he's a Scot.

Anyone out there got any tips fo rationising the relationship between the door and its glass? I am on about how the glass can be controled in its silde into the door without having an opening the size of the humber bridge. Not getting it at the moment and open windows will be important in the scene and renders I am aiming at in the end.

-

I'm not much of car designer, but I have noticed that on most cars, the rear edge of the door glass is smaller and raised higher on the bottom line plane than the front edge. This creates a "hip" at the so called "B" pillar, resulting in smaller windows for either the rear passenger area or the "C" pillar windows if they exist.

In other words, almost all cars use the wedge shape with the rise in the incline being from top front (lowest) to back (highest).

-

Sorry, I think you missed my point. The door glass has to be made to retract into the door and I have to find a method of controlling the arc used to both retract the glass into the door AND avoid shattering the glass while using an opening in the door as narrow as possible. Thanks for the reply.

-

Ah. Oops.

-

Sorry guys my explanation is a tad off. I will get it eventually.

-

The actual panels can be as curvy as you like, as long as the slot for the window remains straight. Normally the curvature of the door panels are built up from the straight slot that the glazing slides into. You can have a curved door but with a straight glazing panel, if that makes sense. As long as the straight slot fits within the cross sectional arc of the door card. I hope this helps, stunning start by the way. The glazing needs to be offset into the interior to cut a long story short.

I love the caterham, it just needs an update IMO, which is what you are doing by the looks of things. Caterham is a beautifully refined driving machine, but the exterior styling is just too raw for my liking, I like where this is going.

-

Thanks Oli, I had the luxury of a caterham day at donnington, prior to the circuit being butchered for the failed F1 entry, What looks like a very simple car works well on a circuit with combination fast and slow corners with cambered kinks adding the the fright, err experience. What I HATED was the soaking I got even from spray and the lack of adjustment for seating and pedals. Apparently Chapman had a short body and Looooong legs which makes for interesting times when you cannot find the brake pedal coming up for the short circuit final bend/chicane and the instructor is saying 'OK, brake .....now, now,NOOOOOOOOOOOOOOOW'...............

-

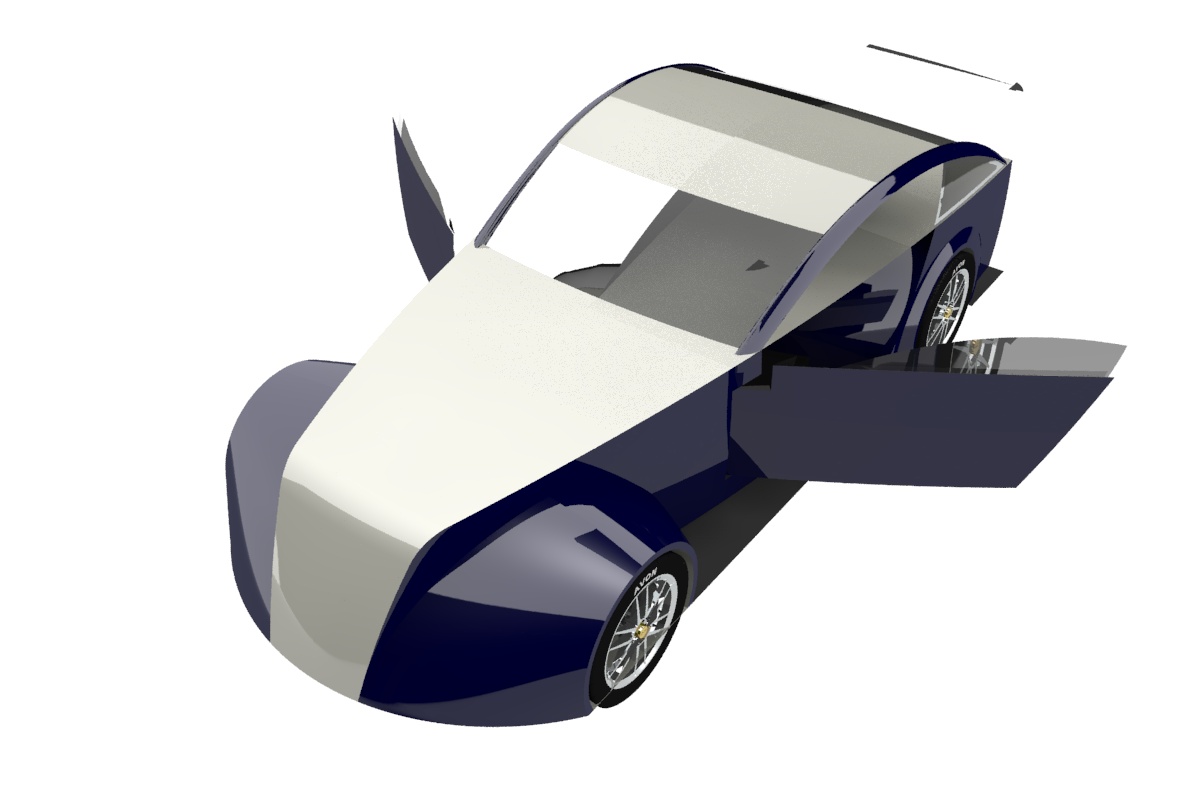

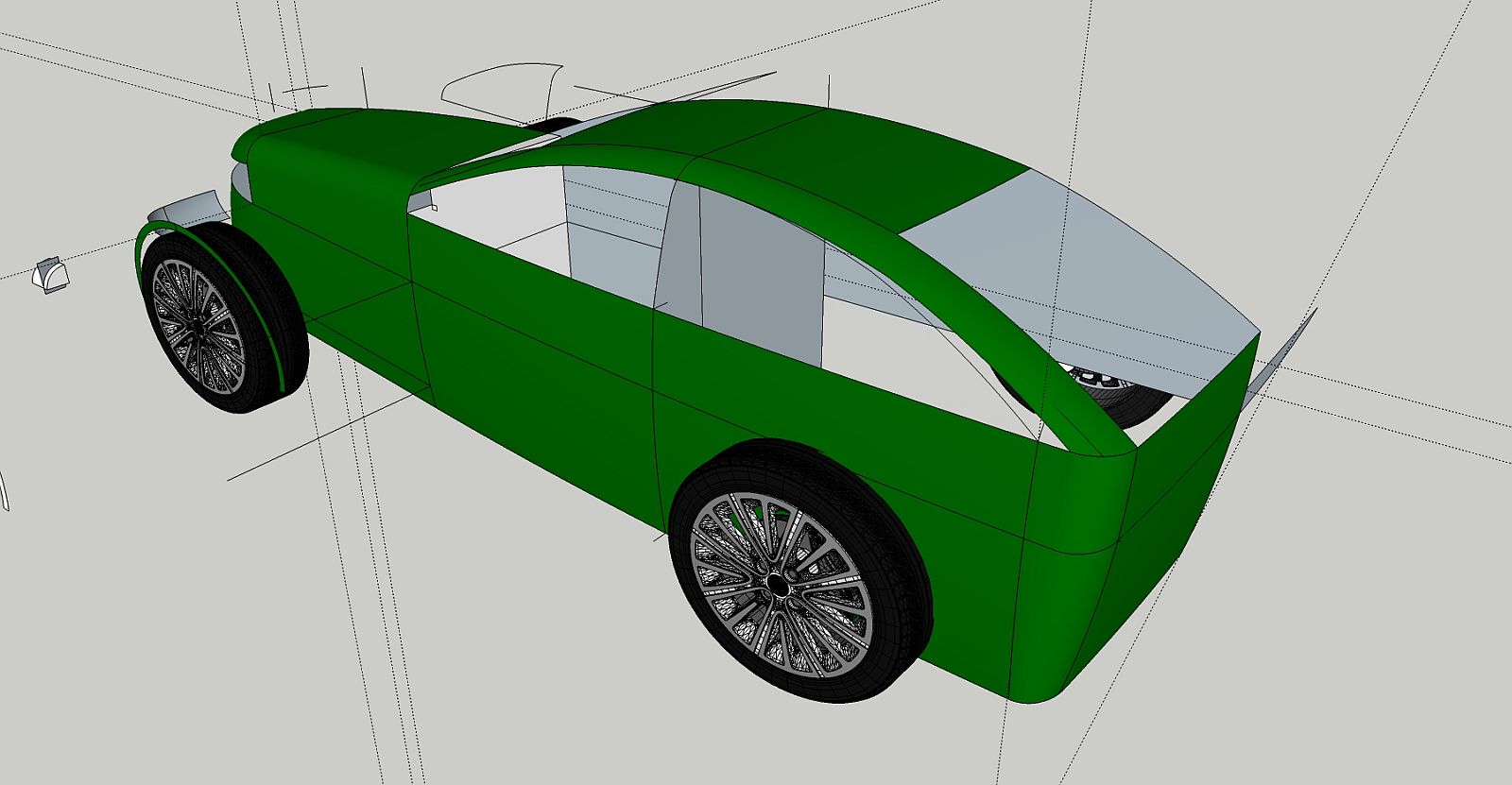

Getting quite frustrated making panels and lines fit, the roof and glazing are particularly difficult, hence the drop top version, I know it is not as sophisticated as some here but I am honing a method that works for me rather than follow the herd.

-

Not finished with that body by any means but I am looking at ways to better integrate roof and body. My problem area with any of my models. Just trying another method here.

-

Change for better resolution of regions, rear end in particular.

-

Follow through.

-

Bits do fit, thankfully.

-

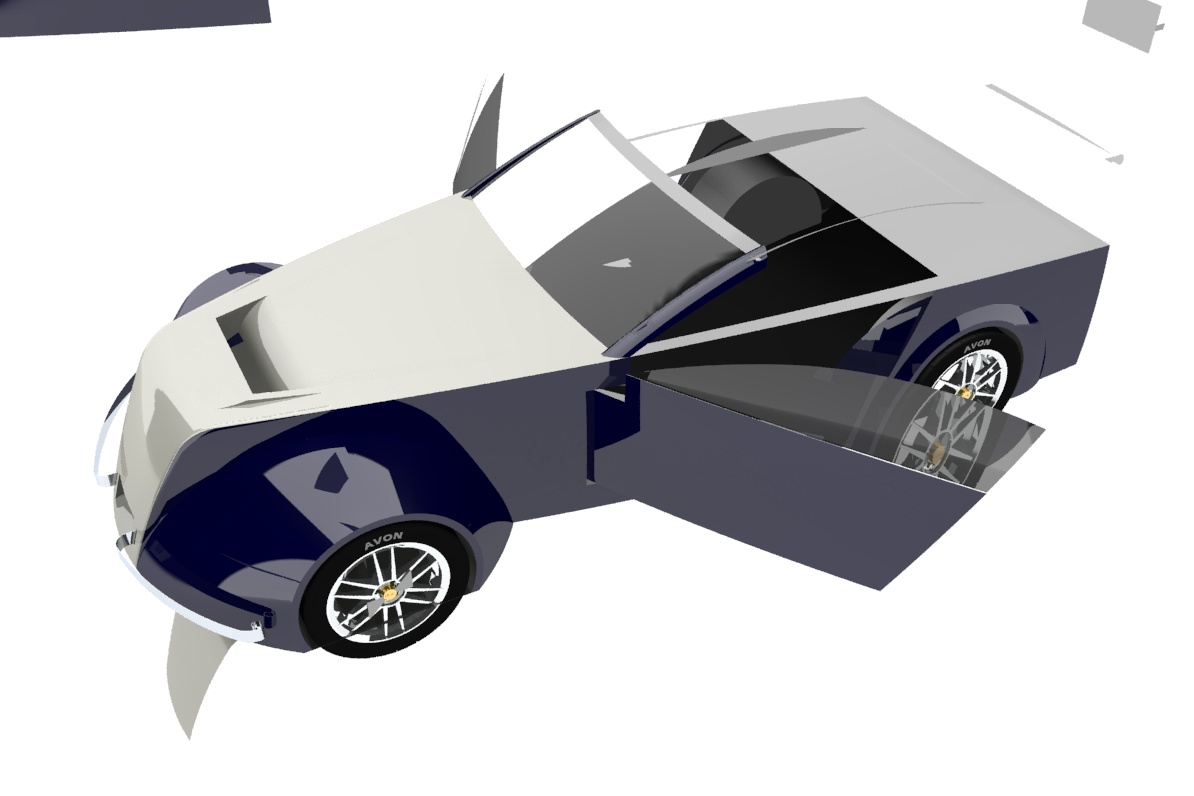

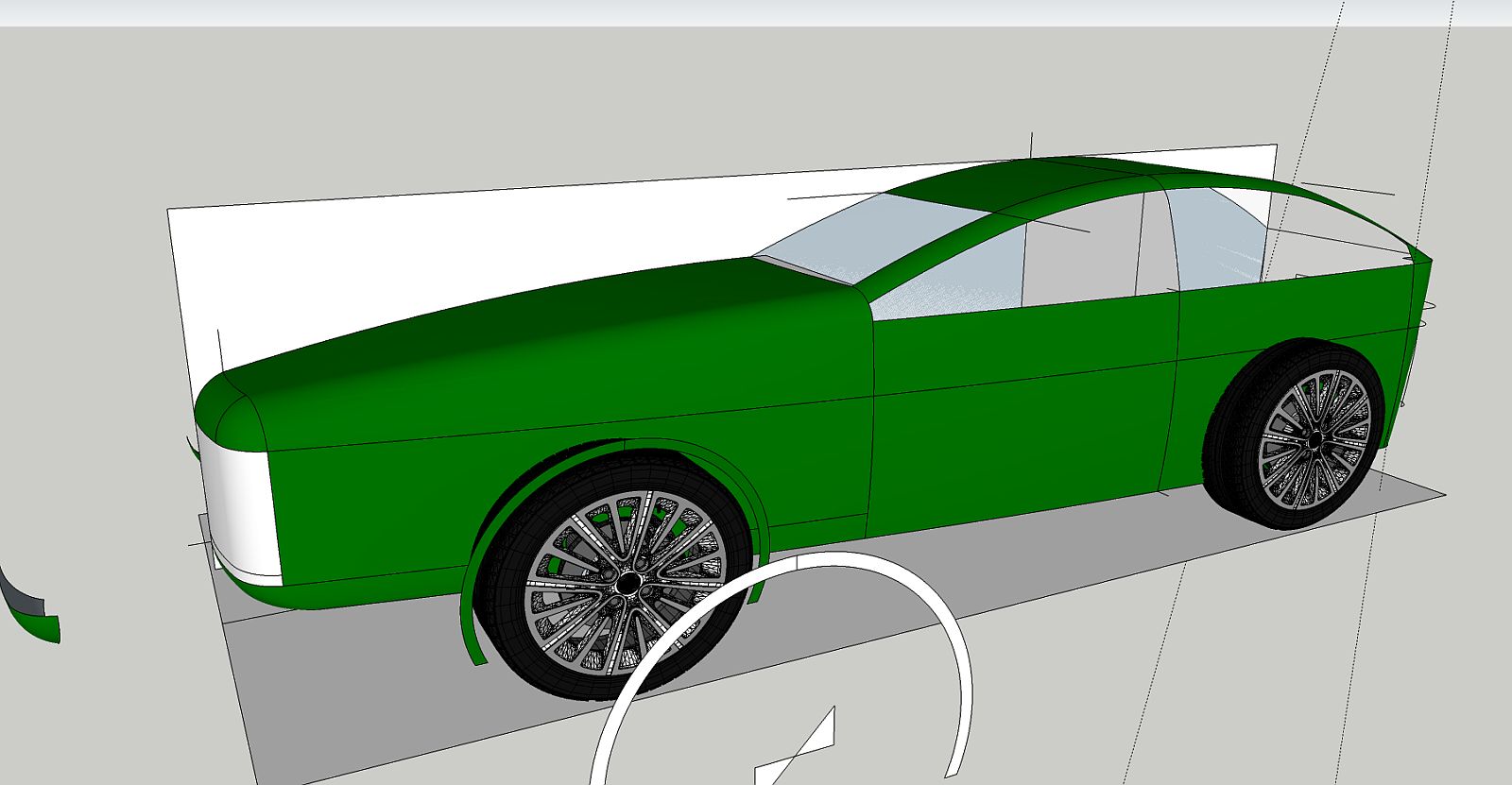

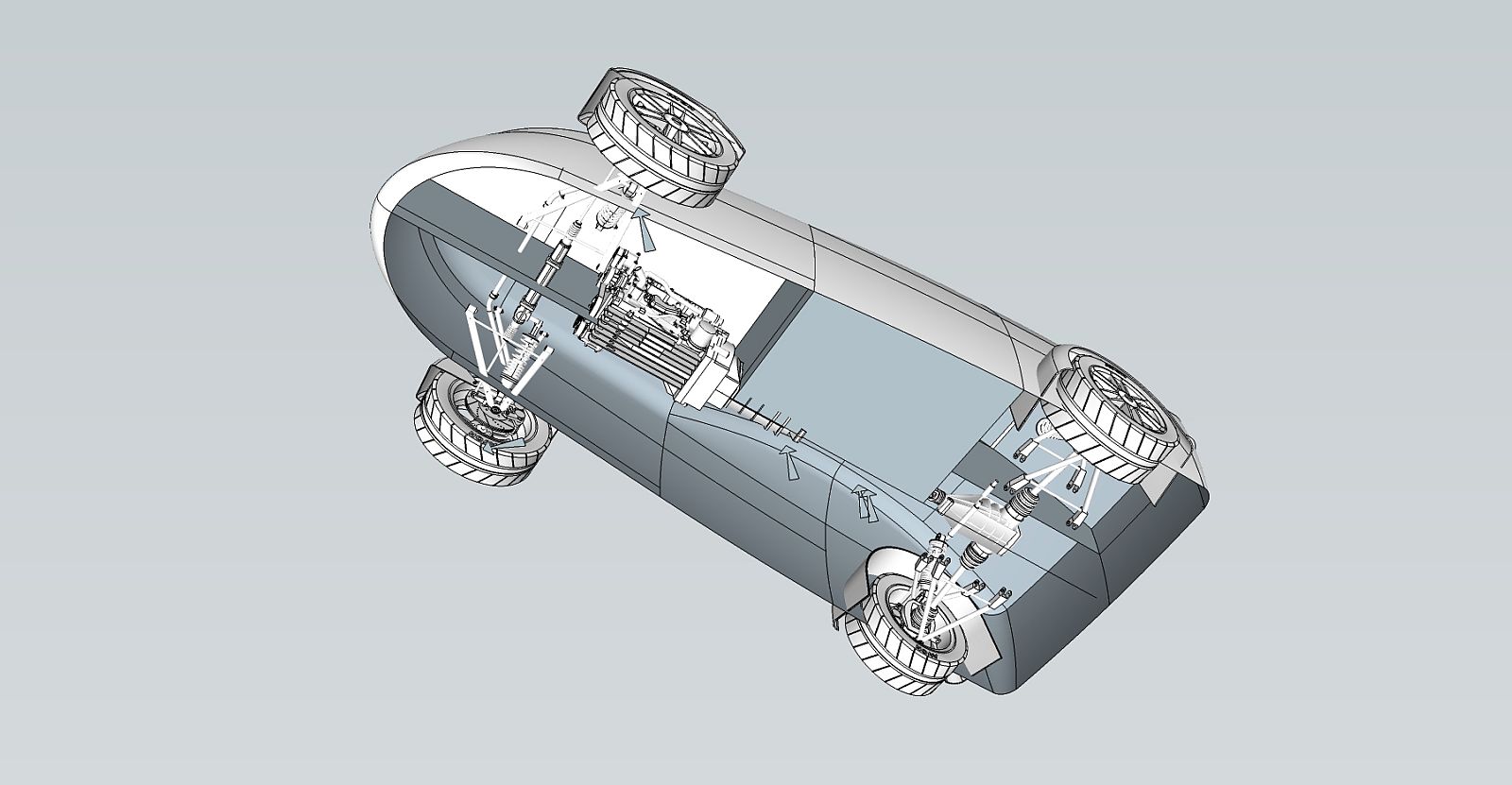

Alternate Style placing the current caterham se7en as a template. There will probably be changes but the body is nearer in size so weight gain will be much less.

-

Body almost complete, cutouts to add and aero aids plus panels and extras. Closer to the caterham still size wise, would probably just drop onto a caterham project chassis.

-

Another view.

-

Hello Mike, it's looking good

It's by no means easy to model a car in SU although

It's by no means easy to model a car in SU although

Elisei makes it look like a walk in the park! I could watch his video's all day.John

-

Wow! Looking good!

-

Cheers chaps, I reckon I am stuck using a non standard method of build, I just cannot shift it.

-

Hello Mike, are you using TIG's extrusion tools?

John -

There are swings and roundabouts between TIG's extrusion tools and curviloft. They are both about even and where one might not play with a particular component/group the other will, usually, with a bit of fiddling. The usual problems are caused by sketchup terminating a line or arec at a place other than the one I choose, even when it appears to play ball. Sometimes stray hidden lins are the problem which itself goes back to the love sketchup has for adding lines or faces no one wants. String, long, how..........

Advertisement