Component issues

-

Hi

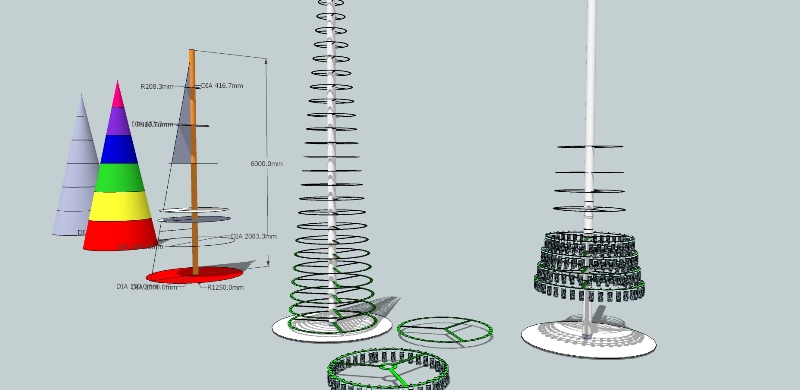

I am trying to create a structure for a 6m high metal frame to make a plastic bottle xmas tree ( hopefully in real life once the commission is agreed)

in Sketchup 8 components used to copy each other, in sketchup 2013 i cant seem to get them to play ball, any ideascheers ashley

-

What do you mean they "used to copy each other"? Do you mean if you edit one component instance all other instances get edited, too? If so, that's still the case in SU2013. Perhaps you've made a group instead of a component?

Post an example SKP file so we can see what you're talking about.

-

@dave r said:

........ Perhaps you've made a group instead of a component?.....

Or you created a component without (right then) replacing the used basic geometry by the component.

Create a component and be sure that this option in the "Create Component" dialog box is checked! Otherwise you still edit basic geometry afterwards. -

many thanks....

ive been trying to use fredo6scale to scale a tower of hoops to a cone but realise this still shrinks the width and the thickness of the hoops not just the width... probably no plugin for that..... hmmmmmmm -

Ah ha! More information leaks out!

If you scale a component with the native Scale tool or with FredoScale, you will only scale the one instance. You must open the component for editing and scale the geometry within to have all instances edited.

That said, scaling is probably not the right tool for the job, no matter whether it is the native one or Fredo's. As you have found, scaling the radius of the hoop results in scaling the thickness of the hoop as well. It would be better to draw each hoop individually. Probably faster than monkeying around with trying to sort out the thickness of the hoops scaling too.

-

Yes, me think you are correct obei-one, the trouble with all these great plugins and tools is that I always look for a shortcut to complicated things.

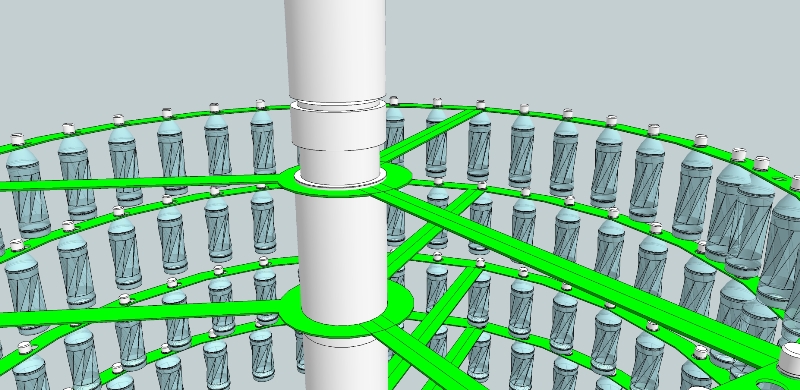

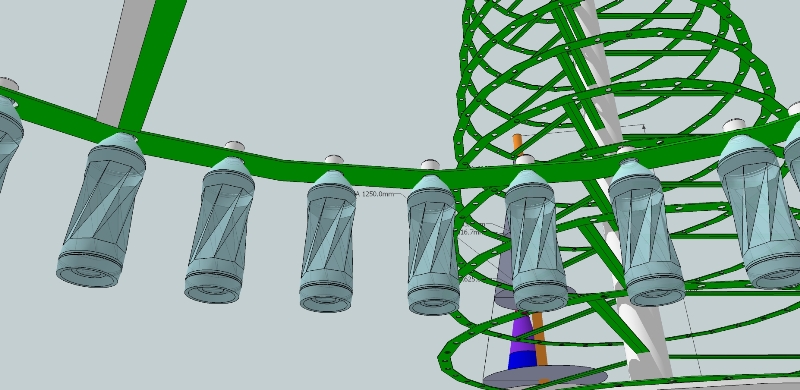

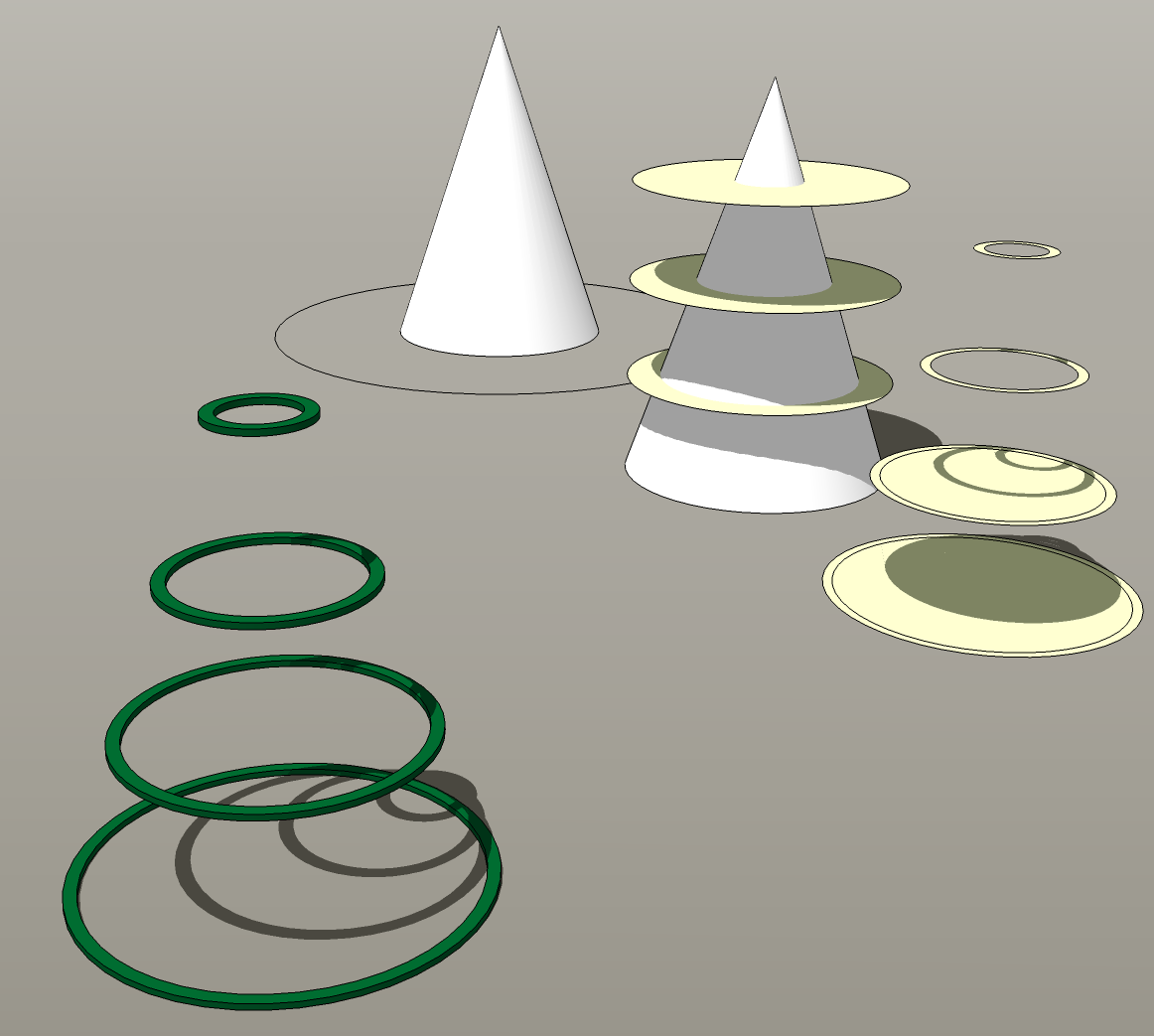

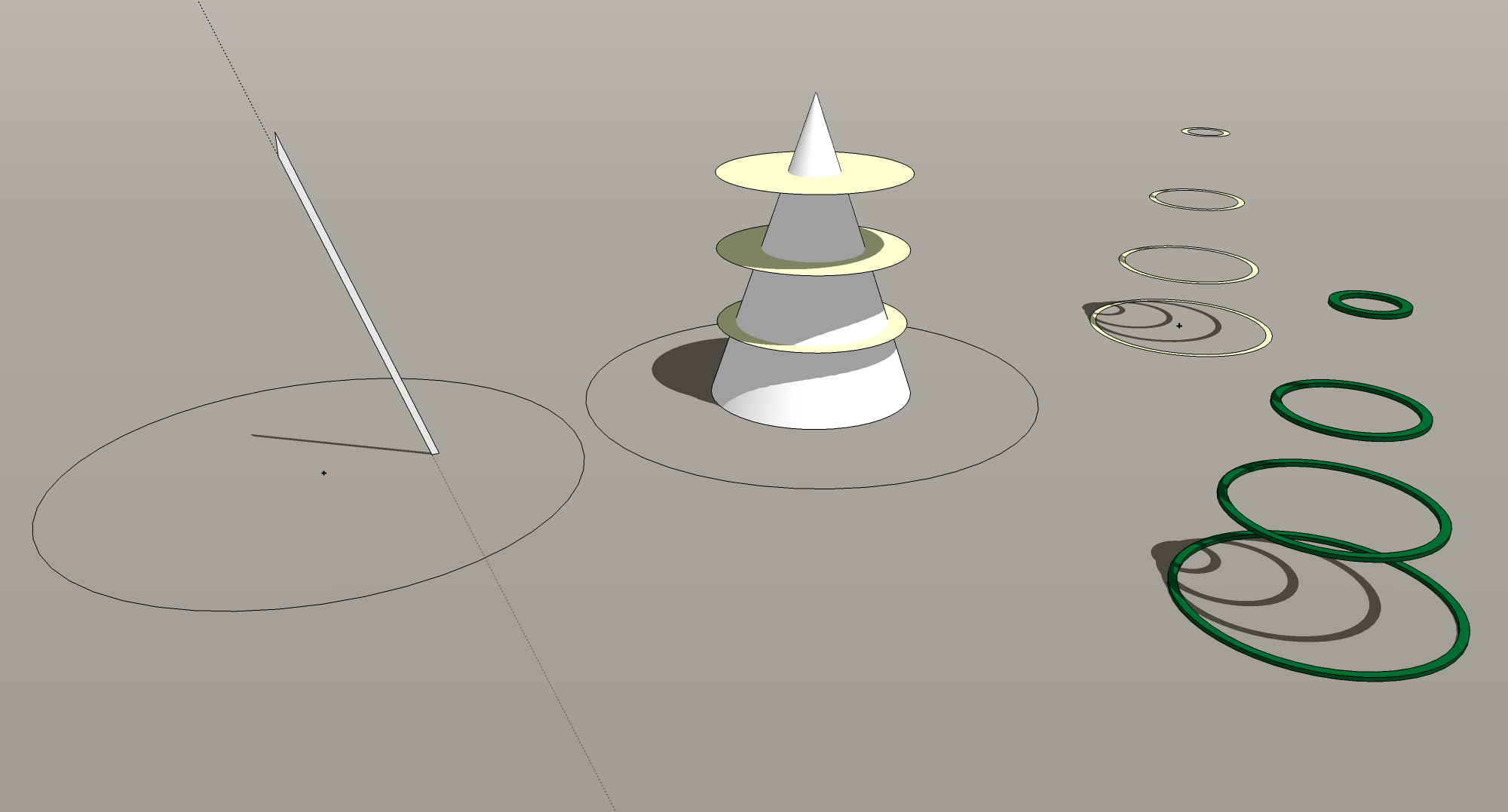

Thanks for the advice, now to do the repetitive hoop and hole making, some images attached in case you have a genius shortcut idea. The file sis too big to upload.

cheers ashley

'the trouble with making some thing fool proof? never underestimate a fool'

-

It's clearer now.

Your comment about making things foolproof is well put. I see that frequently in my day job.

So as in other things, sometimes you need to sneak up on the problem from another direction. Maybe this direction would help. I did this without the use of plugins. I always like to look for a method that uses the native tools first. It's good to know what can be done with them before moving on to the Plugins. Someone else will likely be along with a version that uses all plugins and you can decide how to proceed.

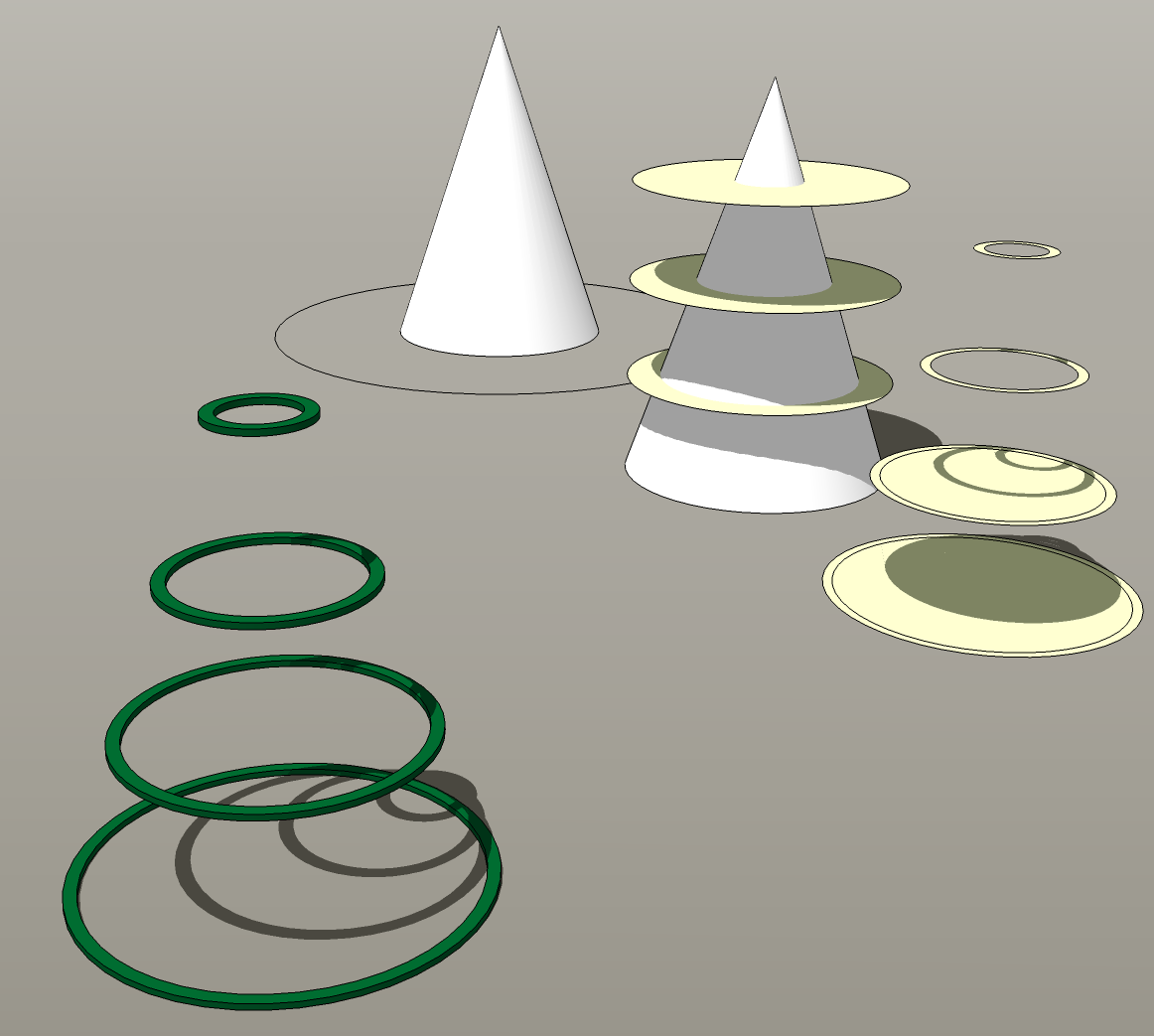

So in the back I drew a cone using Follow Me.

I copied the bottom of the cone up to create slices at the desired spacing.

These slices were intersected with the cone, the cone and other unneeded geometry were deleted. I used Offset to create the the inner circles and deleted the inner faces.

Push/Pull then gave the hoops some thickness.

You could also draw the cone with some wall thickness when making the Follow Me profile and you'd wind up skipping the Offset step although it potentially creates other work.

-

I'm with you Dave when it comes to not using plugins, in this case though you can use Quick Lathe to simply do the repetitive follow mes.

Since your green framework is all the same profile, draw one section and array that in a triangle form. You could then add a circle and follow me each profile or use quick lathe to do it in one. Then you just need to add in your radial arms. These could all be one component scaled in their length or made unique and adjusted to fit each ring before you array them.

Then comes the holes and the bottles, again an easy array job.

Once you have enough of the construction worked out, I would split the structure into a workable segment on the vertical that you can array.

-

hey Dave and Box, i was not expecting anyone to solve this for me and especially in 2 very elegant and 'why didn't i think of that' ways, nice work fellas

many thanks

now I just need to find me a metal fabricator to make it as my guy just mailed and said the job was too big for him!, turning down work in a recession... horse, water..lead... metal horse guy now deadcheers ashley

Advertisement