Geometry Creation Question

-

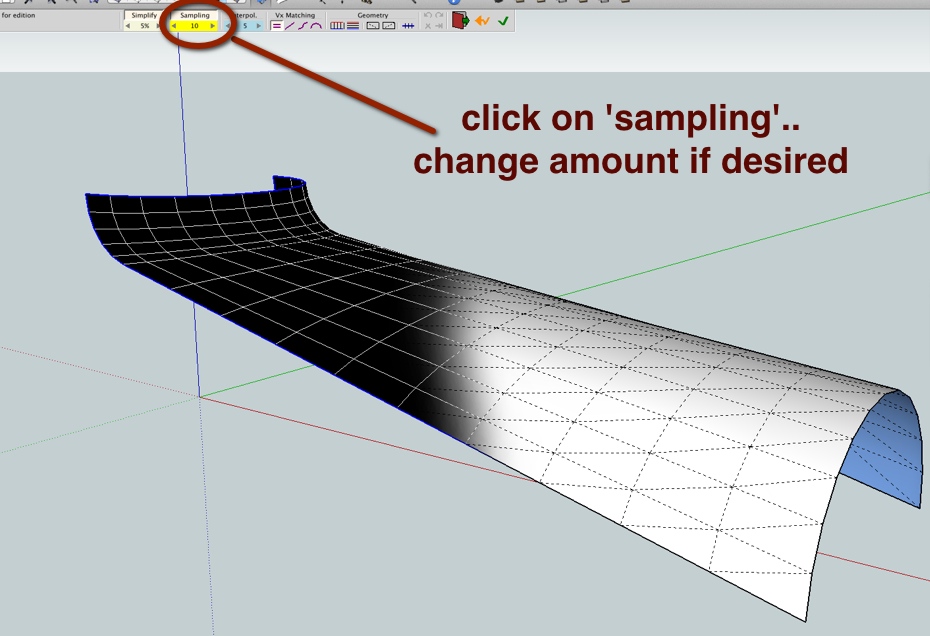

I was working on a leg for a Mid-Century Modern-inspired desk and used Curviloft to create the geometry in the transition between the cross piece and the leg. The piece is shown inverted in the above screen shot. With the hidden geometry turned off, I noticed some unsightly profile edges being displayed along the tapering portion of the horizontal piece. A section shows a sort of saw tooth pattern which explains the profile edges being displayed. I used the same number of segments in the arcs at the ends of the geometry created by Curviloft and in fact they are the same radius. I manually tried to make quad faces instead of thelong skinny triangles but the edges aren't coplanar so the faces won't fill. Any suggestions to eliminate the waviness in the resulting surface?

-

Och! Never mind. I should have just used Follow Me instead. It worked much better. And gave me a better transition.

-

I'm glad we were able to sort that out for you Dave.

-

-

.

Future Reference:

.

-

Tried that. It didn't help in my model. Follow Me worked perfectly, though.

-

On pieces like that Dave, I'm always interested in how would they have actually made that in the real world, with wood. Would you be able to recreate that process in SU? Those cool joints and tapers done in wood are very fascinating and often look complex to me.

Chris

-

Hi Chris,

In the real world you would start with pieces of wood that are a fair amount bigger than the final assembly and shape it down after attaching the parts. I've see several approaches to joining the parts for something like the leg I've drawn. If you want I'll draw a couple of them up for you.

-

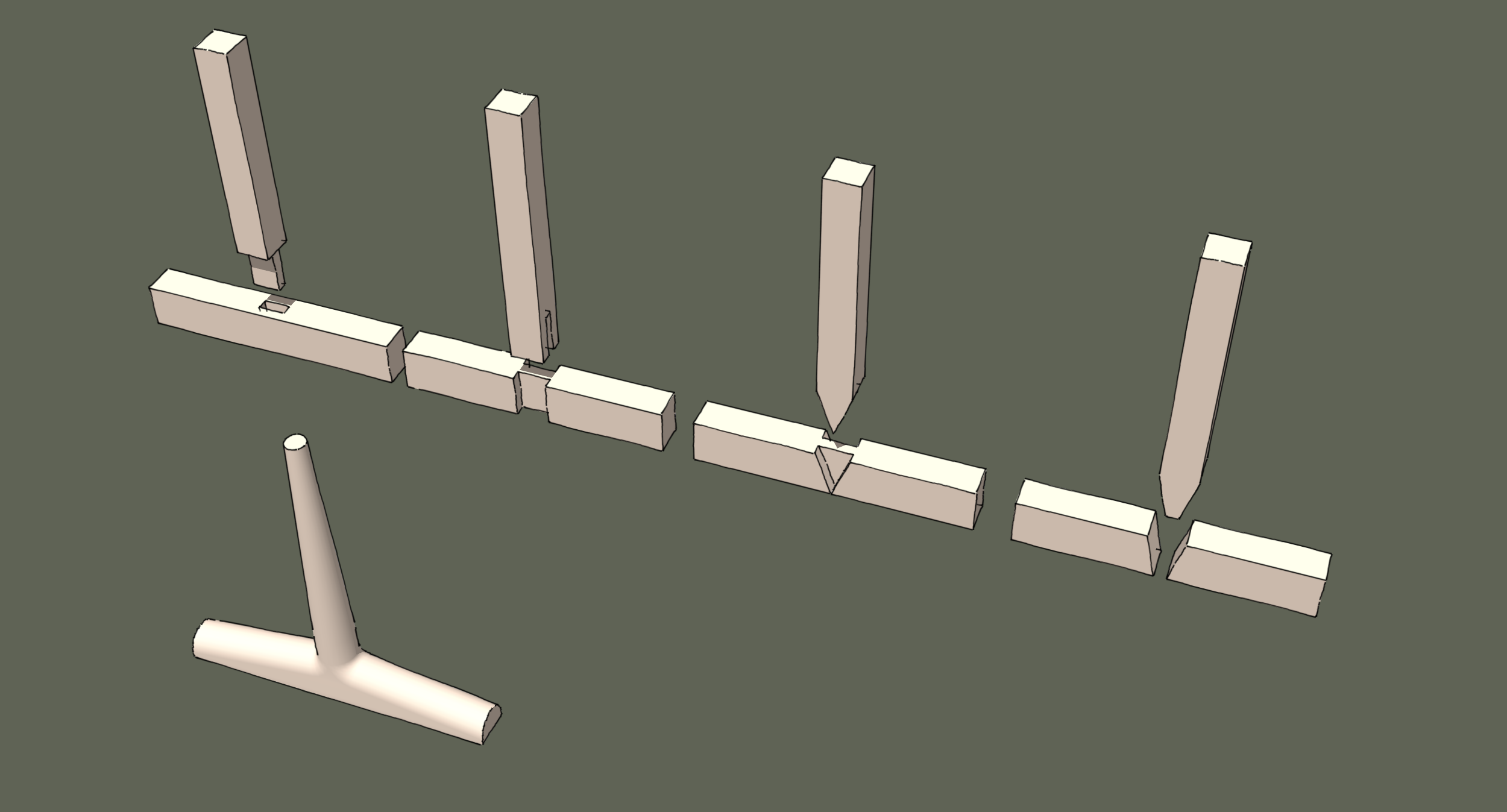

Chris, here are a few examples. There are other possibilities. In any case the blanks are larger than the final leg. As you can imagine you would end up with a different look with each of them due to the way the crossing grain meets. There are other ways, too.

From left to right, Mortise and tenon, bridle, modified bridle, a sort of mitered butt joint. In the last you might use loose tenons or dowels.

On that last one you might have a sort of tongue and groove joint which would make the leg stronger than the dowels of loose tenon.

-

And then how do they get the final tapered shape? A lot of sandpaper?

-

Well-trained termites.

You'd probably rough out the pieces--turn most of the vertical piece on a lathe, maybe--before assembly. Then after assembly finish the shaping. Of course if this was being made in a factory they would be cutting them with a CNC machine. In a home shop you would probably bandsaw the horizontal piece roughly to shape and use a large router bit or shaper to round over the edges. If you notice, I left a straight, untapered section on the vertical piece. This would allow that to be shaped along with the horizontal piece while the tapered section could be turned on the lathe before assembly.

then lots of sandpaper.

-

You can also try to find in the nature a crossing brunch of tree!

it's was like that for some pieces of boat!

here for a sternpost

-

Good knees are hard to find these days, Pilou. and finding four that are T-shaped and the right size even harder.

Advertisement