ENDLESS, fractal workarounds: circles with wrong radii??

-

I don't know what to tell you but I am almost always drawing highly detailed models and I don't have any of the problems you seem to be having. Perhaps our approaches are different. It does sound to me as if you're working too hard to get those holes in your wheel. It would be helpful to see the wheel, though. The way I would do it wouldn't require any plugins at all and I think it would be completed in pretty short order. Again, seeing the SKP file would help.

As to the crashing, I don't know. SketchUp has been very stable for me. Chris Fullmer offered a suggestion. Did you follow that up?

-

I know I must be reading this wrong, and I don't have a correct visual representation of your project. However, from what I understand this sounds like a 10 minute modeling project. So if you could show an image, I would like to see what I am missing or give you a hand.

I model pipe flanges all the time, 6 to 24 holes, 3" to 48" diameter. Takes all of 10 good minutes to model. And your description sounds similar to a pipe flange with the holes near the center instead of next to the rim.

Would like to give some help.

Ken

-

cast alum wheel - 1 of 8 holes made.skp

@unknownuser said:I know I must be reading this wrong, and I don't have a correct visual representation of your project. However, from what I understand this sounds like a 10 minute modeling project. So if you could show an image, I would like to see what I am missing or give you a hand.

I model pipe flanges all the time, 6 to 24 holes, 3" to 48" diameter. Takes all of 10 good minutes to model. And your description sounds similar to a pipe flange with the holes near the center instead of next to the rim.

Would like to give some help.

Ken

Ken,

I'll attach the file from where I last crashed ad nauseum (with one hole made, seven remaining.) Yep, should be very simple. This isn't an important project for me, but I got into it partly to see what I could learn about Sketchup, so the appearance that doing something this simple can lead me down so many dead-ends seems a major warning-sign.

It would indeed be similar to your pipe-flanges (but couldn't you just use the vast engineeringtoolbox.com plugins for just about any such component?) The wheel itself was a pretty simple profile that I extruded circumferentially using the follow-me tool along a circle of the right diameter. Biggest problem for me during that process was convincing SU to draw circles in the plane I wanted (shift key only seems to work sometimes...as often, I would sure like to see some hints in the text-bar for tool modifiers, rather than me having to look up or guess as to whether it might be shift, alt, ctrl, etc) SU also often seems absolutely boneheaded in not being able to find/snap to the origin as a center for a new circle - leaving me to resort to drawing construction lines to help to clue it in.

Also attached a test attempt at the point where I gave up - when SU wouldn't draw a circle of my specified diameter. This problem doesn't reproduce now, for some reason. I suspect that various problems may result from the "hole on solid" plugin, but without that and the bizarre lack of a built-in tool for such purposes...what's a guy to do?

Thanks for your interest and offer to help.

-

What diameters do you want. The diameter/radius of a circle is measure to the vertices, not the flats. How far out from the center are your holes supposed to be? As they are positioned now they won't hit the larger circle at all.

I said before and I'll repeat, there's no need for a plugin to put holes in your wheel.

-

@dave r said:

What diameters do you want. The diameter/radius of a circle is measure to the vertices, not the flats. How far out from the center are your holes supposed to be? As they are positioned now they won't hit the larger circle at all.

I said before and I'll repeat, there's no need for a plugin to put holes in your wheel.

My 1/2" would-be-holes, all eight of them, are on a 9" diameter - 4.5" radius - as shown in the files I attached, assuming they posted OK. The circles you're prolly looking at were my aborted attempt to diagnose the problem: while attempting to recreate the same conditions, SU apparently decided it would no longer draw a 10" circle, whether by mouse-click or data entry, as I complained initially, though that problem seems only to occur on odd days of the week. The other (working) drawing I attached, with the wheel and one of eight holes punched, has a disc of 10" diameter.

If there is a way to punch such holes, well...what is it? If there is a simple method, it seems to be well-hidden from Google searches. If there IS an easy way, why would users like tak2hata be writing plugins to try to come up with a way to do this - in active forums, I note? - see http://sketchucation.com/forums/posting.php?mode=quote&f=323&p=479539

-

You seem to be convinced I'm lying to you about not need any plugins. I assure you I'm not.

Not one plugin was used to create this.

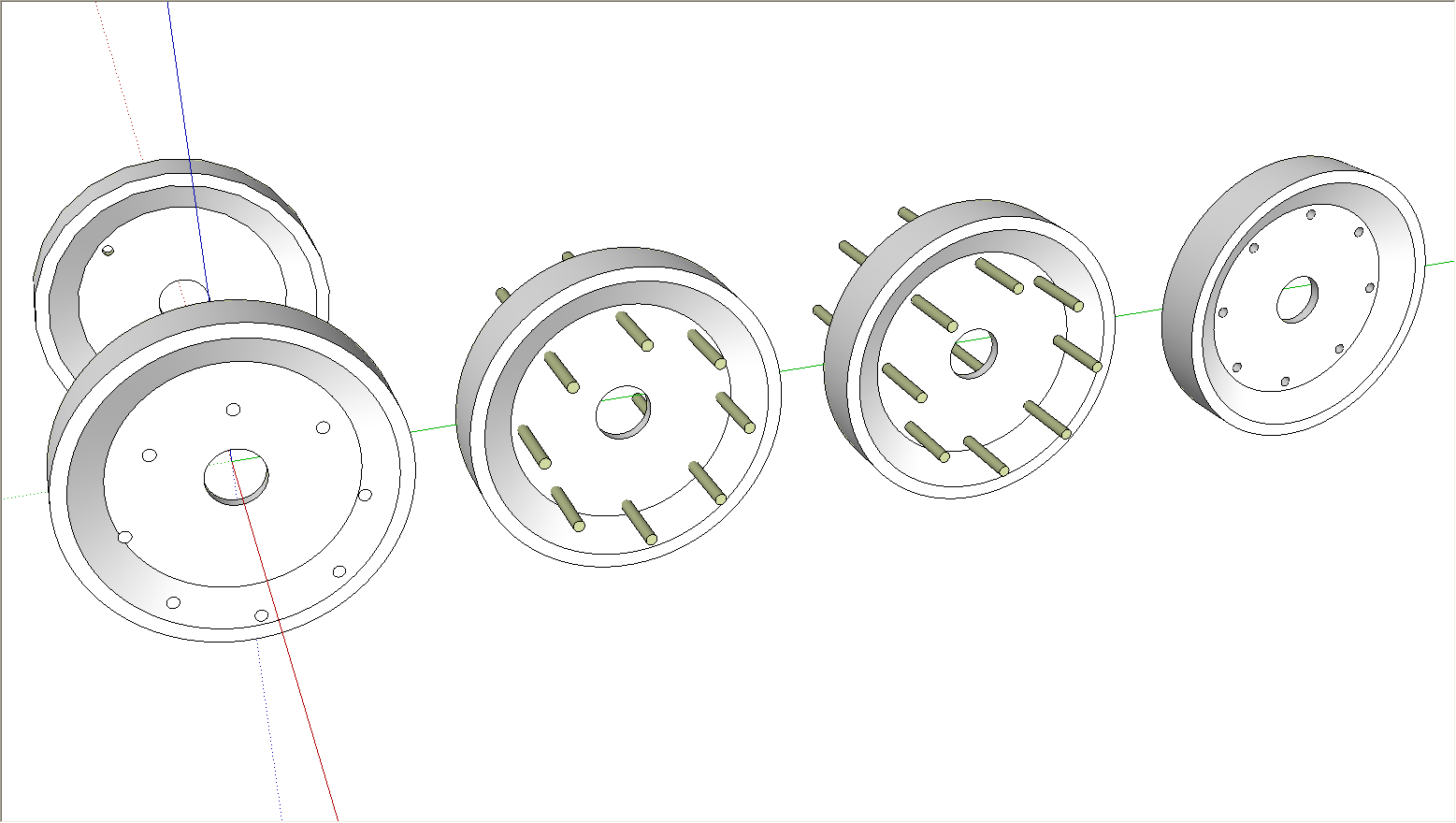

I took the liberty of drawing your wheel so it looks round. Yours has a lot of bad geometry on the opposite side and most of it had reversed faces. So starting from the left.

- The wheel with the circles you drew for punching the holes. The wheel and the holes have to be in the same context. Since you had made the wheel a component you should have put your circles for the holes inside the component, too. In the attached SKP, I just didn't bother making the component until after I finished.

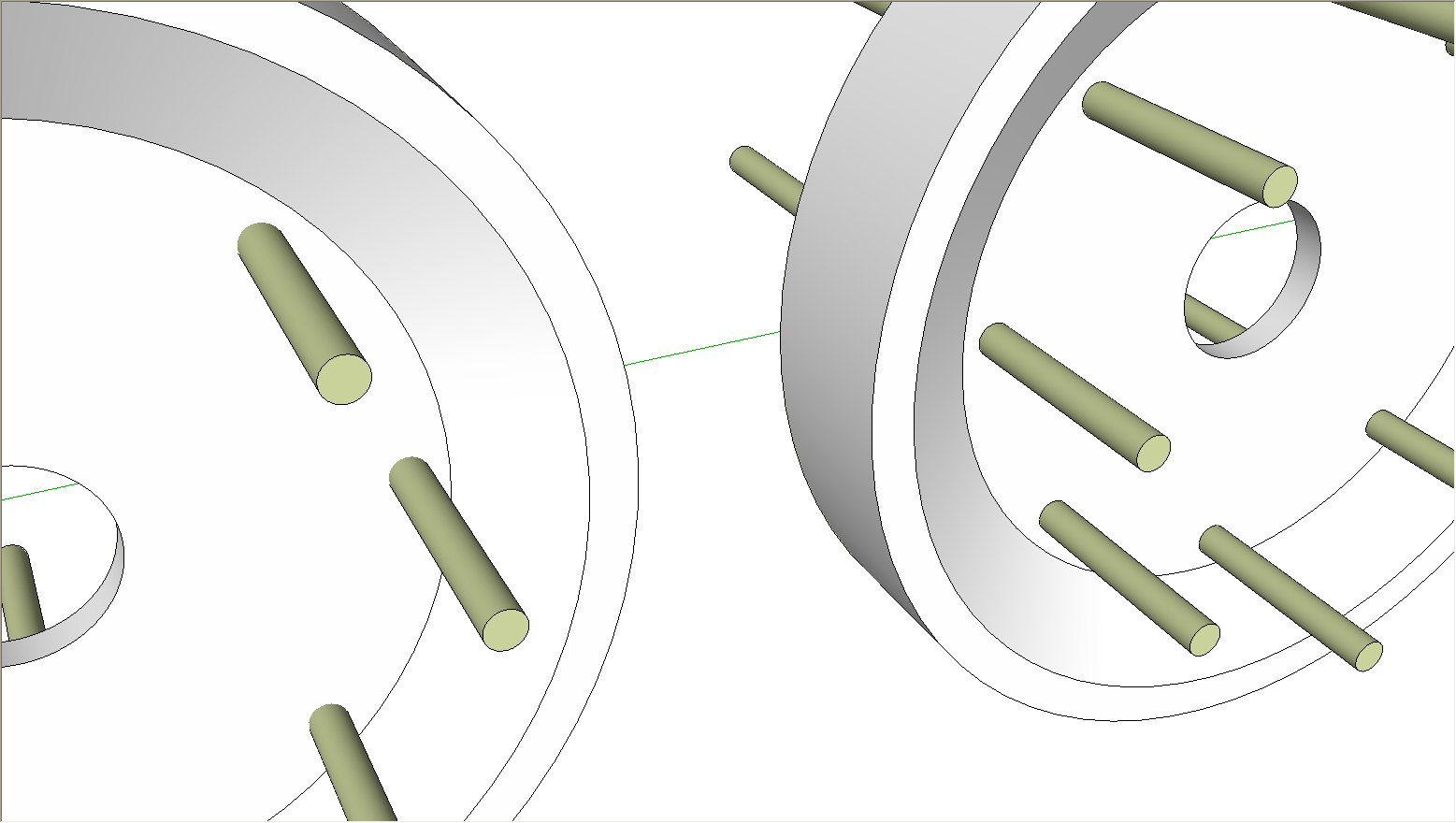

- Push/Pull the circles into cylinders through the wheel. I've reversed the faces on the cylinders because when we get finished with the holes, the front faces will be on the inside of the holes. Notice where the cylinders pass through the wheel there is no edge. There is no intersection between the faces. Here's a close up view.

- I selected all of the geometry of the cylinders and the faces of the wheel. I right clicked on them and chose Intersect Faces>With Selection. Intersections are created where the cylinders pass through the wheel.

- After deleting everything that isn't the wheel we have a wheel with holes in it. A right to left selection box around the ends of the cylinders and a press of the Delete key get rid of most of the waste. Select the faces skinning the holes and delete them. Make the thing a component and you're finished.

It takes longer to read this than it does to do it.

-

With a Pro 8 version (that I have not) it's better to make a boolean Difference or not ?

-

Hole on solid works fine as far as the component IS solid.

-

Thanks for attaching your file. Attached is my solution. I am using native tools in my solution. However, in real life I use one of two plugins, either TIG's "Extrude Edges by Lath" or Trogluddite, "Quick Lathe".

I use Trogluddite, "Quick Lathe" when making object from ACAD files.

Hope this helps.

Ken

-

Ken, that's good. I worked from Dave's starting point with his "holes" not drawn on the surface but drawing them on the surface of the wheel would have made punching the holes easier because it would simply be a Push/Pull operation through to the opposite face. No erasing/deleting to do.

-

Here's a simpler way if the circles for the holes are drawn on the web of the wheel directly. For something like this I wouldn't worry about grouping the wheel until the holes are completed. Then I'd make it a component, not a group.

Again, no plugins used. Using a plugin for this one would be like driving a map pin with a sledge hammer.

-

Good morning Dave

A quick question, what video screen capture do you use? I haven't found one that I like.

And on another note, at the next base camp, I see "the hat" is going to be required in the dress code. A thomthom-hat or for short its called a "that", another trend setting apparel.

Ken

-

Ken, I did this on my XP machine and used Snagit 10 for the capture. I've been testing Captiva on my Win 7 machine. It'll do higher res video and has a video editor built in. Snagit has done a decent job, though. I tried a number of freeware and very low cost screen capture apps but they had problems keeping video and audio synchronized.

I think I'll have to find my own "that" for the next Basecamp. That's a great idea.

Advertisement