Follow-Me tool problem

-

Hey forum, quick question:

Has anybody experienced this before?

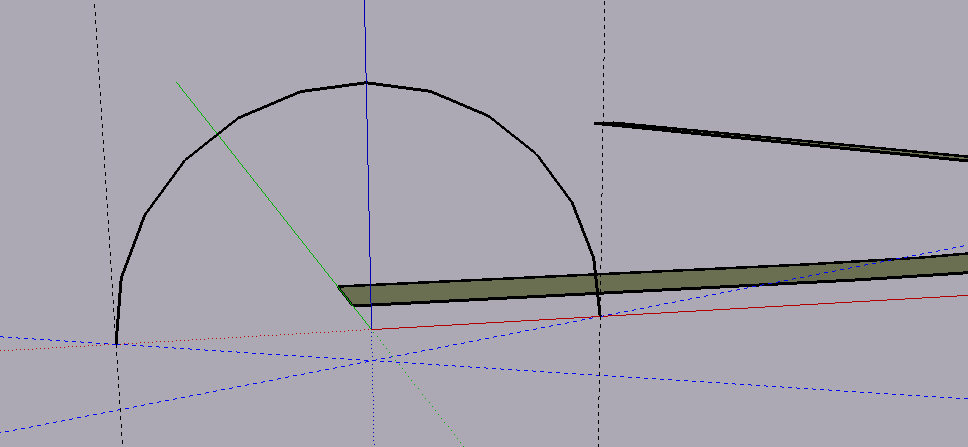

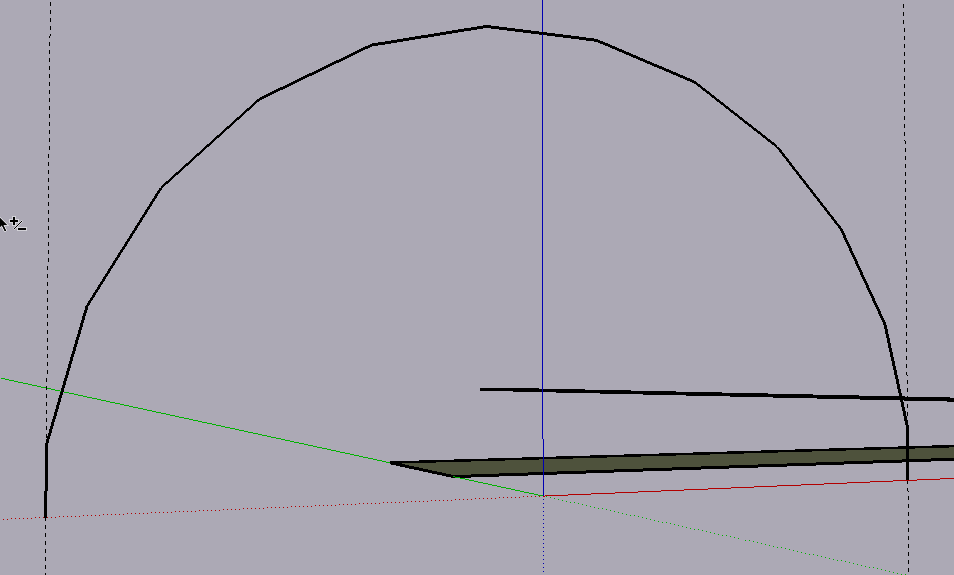

I create a shape, a circle, cut the circle in half and use the follow-me tool to guide the shape around the half circle. Perfectly routine stuff, when suddenly:

What the hell, Sketchup?

I can't believe I'm being held up for so long by something that seems so simple, yet I can't seem to find whatever is causing this... I'm sure I must be missing something really obvious

Does anybody have an idea as to what could be causing this? Here's the file: Heatshield.skp

Thanks in advance,

Kevin

-

-

@unknownuser said:

.

@bunnyack said:

I'm sure I must be missing something really obvious

nope.. you're not

Thanks, Jeff. Instantly soved my problem.

-

-

Lathe might solve this specific problem for you but I think it is important to understand what is happening and how to avoid it. There are cases where you won't be able to use Lathe to do what you are trying to accomplish and you should to know how to solve it without a plugin. This isn't a problem with Follow Me. It's a problem with the way it is being used.

It is important to understand that Follow Me extrudes a profile that starts out perpendicular to the first segment in the path and ends the extrusion with the profile perpendicular to the last segment in the path. If you don't place the profile perpendicularly to the first segment, SketchUp will rotate before starting the extrusion. Actually it is a projection and that deforms the profile although it is often not that noticeable unless the angle between the profile and start of the path is great.

In your example you have the above situation. You drew an arc for the path for Follow Me. The first and last segments of the path are not perpendicular to the ground plane. As you found, SketchUp did what I described above and so the profile at the beginning and end are perpendicular to those first and last segments.

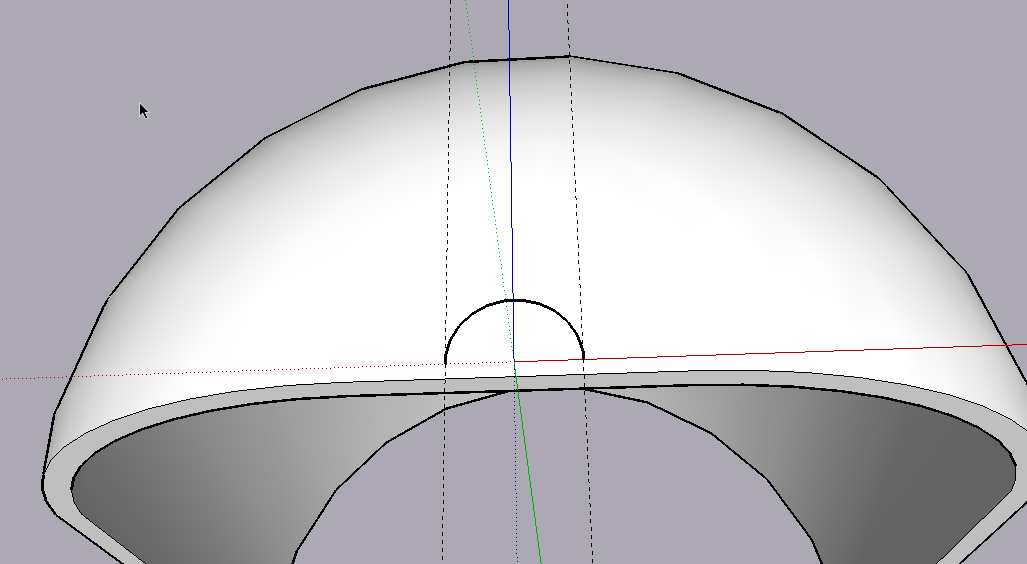

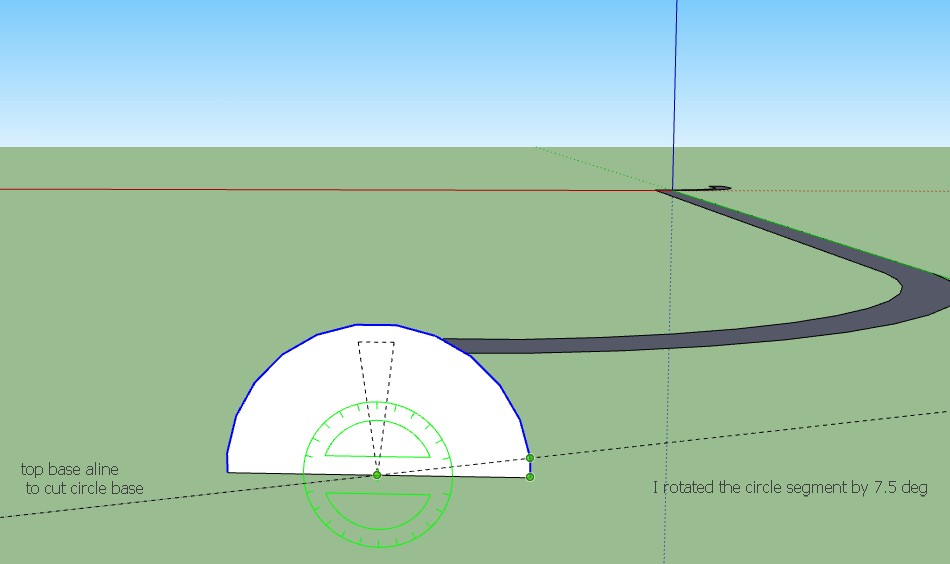

Here I've set up the path so the first and last segments are perpendicular to the ground plane. I did that by using a circle instead of the Arc tool. I drew the circle with the radius dragged out along an axis line and then I rotated the circle half the angle between vertices. I used a default 24 sided circle so I rotated the circle 7.5 degrees. I drew a line along the red axis to to split the circle in half and deleted the bottom half as well as that diameter line.

So after running Follow Me using that path, i get exactly what you were expecting.

Lathe will work fine if you would have drawn a circular path but suppose the curve is just part of it. For example, to draw the chamfers on these stretchers for a hayrake table, I had to make sure I started my profile perpendicular to the first segment in the path. In that case I wound up drawing the paths longer than the chamfers so the extrusion started before and ended after the stretcher. I did a blog post on how I did those if you're interested.

-

@unknownuser said:

Dave is the Ruby coder killer!

Why this mysterious 7.5° my dear Holmes?

24 * 7.5° = 180°

Elementary my dear Watson!

Exactly! As I said, half the angle between vertices.

Pilou, I think only you would use 32 segments for a circle. I got in the habit long ago to use segment counts that are factors of 360 for circles and arcs. There are a few instances where I wouldn't but not very many.

-

Dave is the Ruby coder killer!

Why this mysterious 7.5° my dear Holmes?

24 * 7.5° = 180°

Elementary my dear Watson!

Careful with 32 segments that will be 5.63° with 2 decimal points

but 32 * 5.63 = 180.16°

So take 5.625° !

32 * 5.625 = 180°

etc... -

"I rotated the circle half the angle between vertices. I used a default 24 sided circle so I rotated the circle 7.5 degrees. I drew a line along the red axis to to split the circle in half and deleted the bottom half as well as that diameter line."- Dave

Dave your right

Bunnyack here the fix segment

Heatshield_dj.skp

-

@dukejazz said:

"I rotated the circle half the angle between vertices. I used a default 24 sided circle so I rotated the circle 7.5 degrees. I drew a line along the red axis to to split the circle in half and deleted the bottom half as well as that diameter line."- Dave

Dave your right

Bunnyack here the fix segment

[attachment=1:1mbh0vnp]<!-- ia1 -->Heatshield_dj.skp<!-- ia1 -->[/attachment:1mbh0vnp]

[attachment=0:1mbh0vnp]<!-- ia0 -->pic_0125.jpg<!-- ia0 -->[/attachment:1mbh0vnp]Thanks, pal

In this case, lathe worked fine for me, though. And thanks for the explanation, Dave.

In this case, lathe worked fine for me, though. And thanks for the explanation, Dave. -

Hi folks.

I such case it is probably faster to lathe a full circle and then delete the unwanted half.

Just ideas.

-

yes but you have an half chance to take end-end segments / against middle-middle of segments and even end-middle!

Advertisement