Is this even possible using just one plugin???

-

Peter,

RE:"But I sense the request is as much about working with solids as a particular project". Indeed, you are correct

Bob

-

sketchup could use a WireCut tool as found in rhino (whose 'solids' are similar to SU solids)

on a basic level, it's like zorro except it will split one solid group into two solid groups..

(other wirecut options include depth of cut, which half to delete, keep both halves, probably other things that I'm not thinking of right now.. but even the no frills version would be good in sketchup)

-

@unknownuser said:

sketchup could use a WireCut tool as found in rhino (whose 'solids' are similar to SU solids)

on a basic level, it's like zorro except it will split one solid group into two solid groups..

(other wirecut options include depth of cut, which half to delete, keep both halves, probably other things that I'm not thinking of right now.. but even the no frills version would be good in sketchup)

Perhaps try my two solid-tools additions - 'Cut_to_plane' [splits it and keeps one part to one side of plane [3pt-pick determines plane's normal and what is kept]] and 'Split_to_plane' [splits it into two parts at a plane, from 3pt-pick] ? Their new group[s] keep[s] the original's materials, layers, naming etc...

-

With TIG's tool, you set instead a face. Rotate on one axis then the second. It's pretty similar to having a dialog and more hands-on as you set the blade where you want it. Even with a miter saw I am constantly checking "right-hand?... or is it left-hand?", heh.

Perhaps I don't understand the overhead wire cutting, but once you go beyond vertical cuts it seems it's a lot easier to manipulate a face than your camera view.

I like most using Profile Builder and Dave's component building method after, if you desire to get pieces for the building take off. There is one big drawback--the miters do not receive an edge on horizontal surfaces, so Zorro2 steps in.

-

@tig said:

Perhaps try my two solid-tools additions - 'Cut_to_plane' [splits it and keeps one part to one side of plane [3pt-pick determines plane's normal and what is kept]] and 'Split_to_plane' [splits it into two parts at a plane, from 3pt-pick] ? Their new group[s] keep[s] the original's materials, layers, naming etc...

[eDit]- all of the following RE: Split_to_plane.. i'll try Cut a little later..

uh.. wow.. missed that one

very nice TIG! that's exactly what i was thinking of in my earlier post..

(actually, i like the way you did it better than what i was thinking of )

)

@bsintzel said:

Upon second review, I found it to be satisfactory in that I didn't have to create a separate 'cutting' plane, then a 3pt-pick.

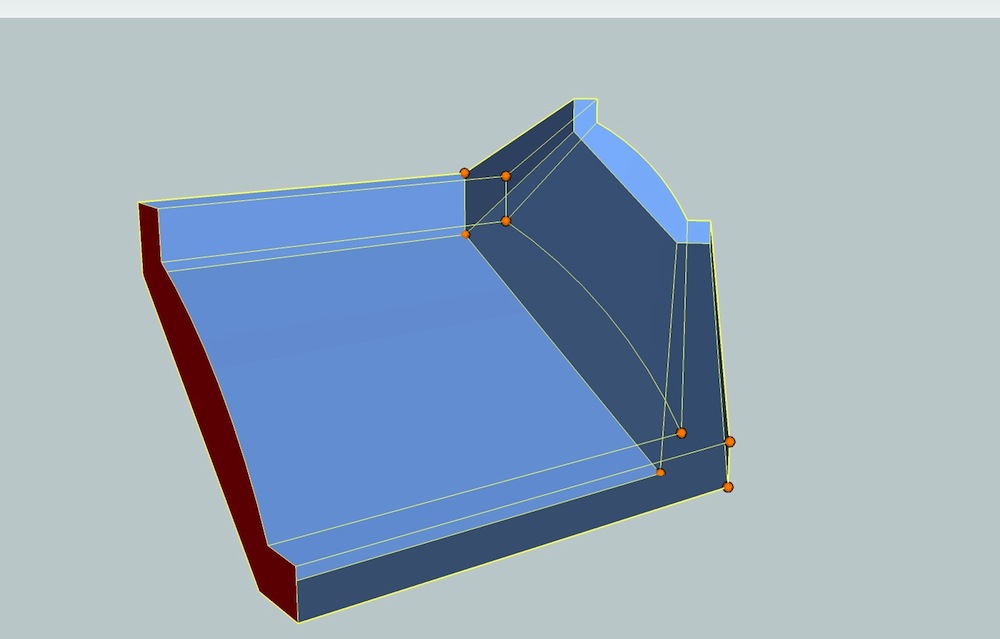

right.. any 3 of these orange dots will define the plane you need.. (and that's not even counting the vertices of the curved section..

@bsintzel said:

I just wish that, like cutting a cove molding with a compound miter saw, I could 'set' the angle and normal of the cut 'before cutting, I'd have it all in one plugin.

maybe think that through a bit more.. when using a compound miter saw, setting the angles are a process.. albeit not a hard or complicated process but definitely more work than making the cut.. in sketchup, the angle knobs/dials/guides etc are already there in the vanilla tools.. i don't really see what TIG could add to this plugin which would make the cut any faster..

(in fact, i think adding more to the tool would clutter it up and possibly slow down the process.. especially if dialog boxes and what not start popping up when all you want is the 3pt click) -

@pbacot said:

Also looking at your top post... I wouldn't be using this for crown molding anyway. I would use the follow me or profile builder to run molding.

you would still use follow me in this scenario.. then cut it into individual pieces using TIG's plugin..

the extrusion will also give you all the layout points needed to make the cut (or-- that example img i posted up there ^ was the red profile follow-me'd along a line with a 45º kink.) -

@unknownuser said:

maybe think that through a bit more.. when using a compound miter saw, setting the angles are a process.. albeit not a hard or complicated process but definitely more work than making the cut.. in sketchup, the angle knobs/dials/guides etc are already there in the vanilla tools.. i don't really see what TIG could add to this plugin which would make the cut any faster..

(in fact, i think adding more to the tool would clutter it up and possibly slow down the process.. especially if dialog boxes and what not start popping up when all you want is the 3pt click)ok.. so a faster way for this to work would be.. (ha!)

the plugin would work exactly like follow-me except anytime the line kinks, the extrusion is split & grouped separately.. if parts of the line are welded then the split/group doesn't happen (similar to what follow-me does with hard_or_soft lines depending on if the path is a SUcurve or collection of segments)

[EdiT]- but this is an entirely different thing than the Split_to_plane.. that one should stay as is

-

@bsintzel said:

Hi Jeff,

I think that TIG's cut-to-plane will work for me. As Peter said,"you set instead a face. Rotate on one axis then the second" is pretty much what I'd do on a miter saw. Thank you all for your input.

Warm regards

Bob

right..that's definitely one way to use it (and how i foresee myself using it with my own stuff).. just seems in the case of molding, it would be better to extrude as one then cut it up with split_to_plane.. no need to move/rotate a separate plane around because key intersections have already been made..

(but then again, i'm just assuming what you're trying to accomplish so this idea might not be so good in your scenario.. ) -

Hi Jeff,

RE:"i don't really see what TIG could add to this plugin which would make the cut any faster..

(in fact, i think adding more to the tool would clutter it up and possibly slow down the process.. especially if dialog boxes and what not start popping up when all you want is the 3pt click)"I typically use the follow-me tool to place crown moldings on my models. It works very well except that when I want to move one section of the molding (for illustration purposes), I could not do so easily i.e., there was just one solid. After a few messages back and forth with TIG, he came up with an elegant solution...a hot-wire-like mod to his split_to_plane plugin. It now allows me to cut out a section from the solid by simply drawing a construction line across the solid group, pick two points along the cutting line on either side of the solid group then hit the 'enter' key. It's simple, fast and works just like a miter saw in real life. I think any woodworker (like myself) will want this new mod

Bob

-

TIG,

Well, I had another look at your split-to-plane plugin. Upon second review, I found it to be satisfactory in that I didn't have to create a separate 'cutting' plane, then a 3pt-pick. The fact that the 3pt-pick determines plane's normal, as well as the placement of the cut makes it quite usable...so expect payment.

I just wish that, like cutting a cove molding with a compound miter saw, I could 'set' the angle and normal of the cut 'before cutting, I'd have it all in one plugin.

warm regards

Bob

-

Hi Jeff,

I think that TIG's split-to-plane will work for me. As Peter said,"you set instead a face. Rotate on one axis then the second" is pretty much what I'd do on a miter saw. Thank you all for your input.

Warm regards

Bob

-

@bsintzel said:

. I think any woodworker (like myself) will want this new mod

yeah, i saw that. good stuff!

-

Ok Gents, I give up. Wondering if this post addresses my challenge on Compound Mitered Cuts. Have a Trim-Moulding running paralel to a set of stairs. Problem comes when stairs walls make a 45 deg turn and Follow-Me rotates the extrusion along the Z axis.

Tried couple of scripts. Could not find the right one.

Model attached. Any help will be appreciated.

Regards

Nino

-

Ninomayda have you tried "follow me and keep"?

-

@box said:

Ninomayda have you tried "follow me and keep"?

FM & Keep . . . . Have not tried it, is it a PlugIn? I'll look.

-

FAK...

-

That's the ticket! Superb Solution. Thanks a bunch to Wikii ! Great Job.

Thanks to all . . . . again.

Nino

Advertisement