Lining things up

-

Alright, so this was quick. I just made up the parts out of my head and I did this all between my last post and this one.

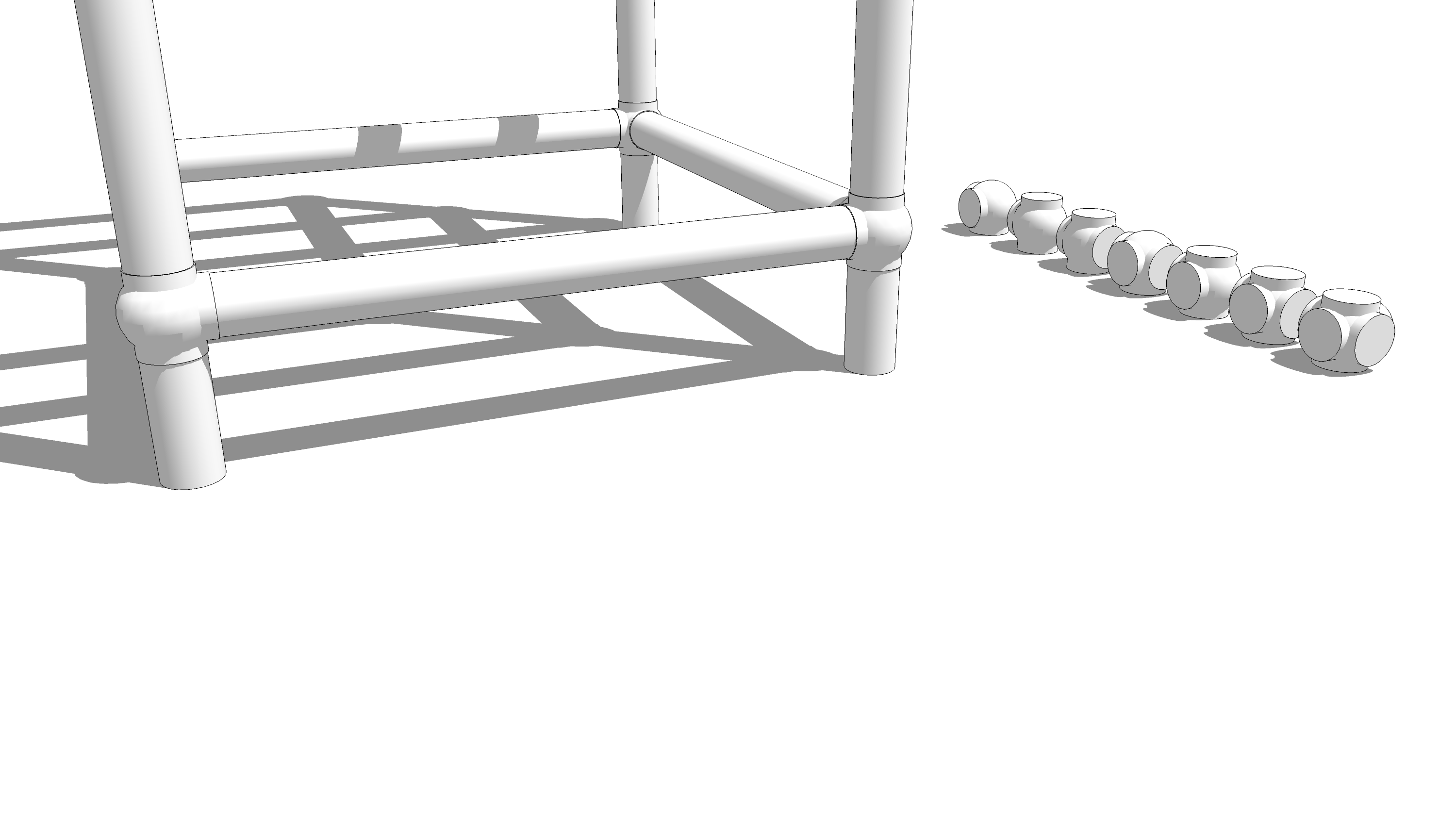

Here are some joint units. Each is a component. I probably missed some combinations, too.

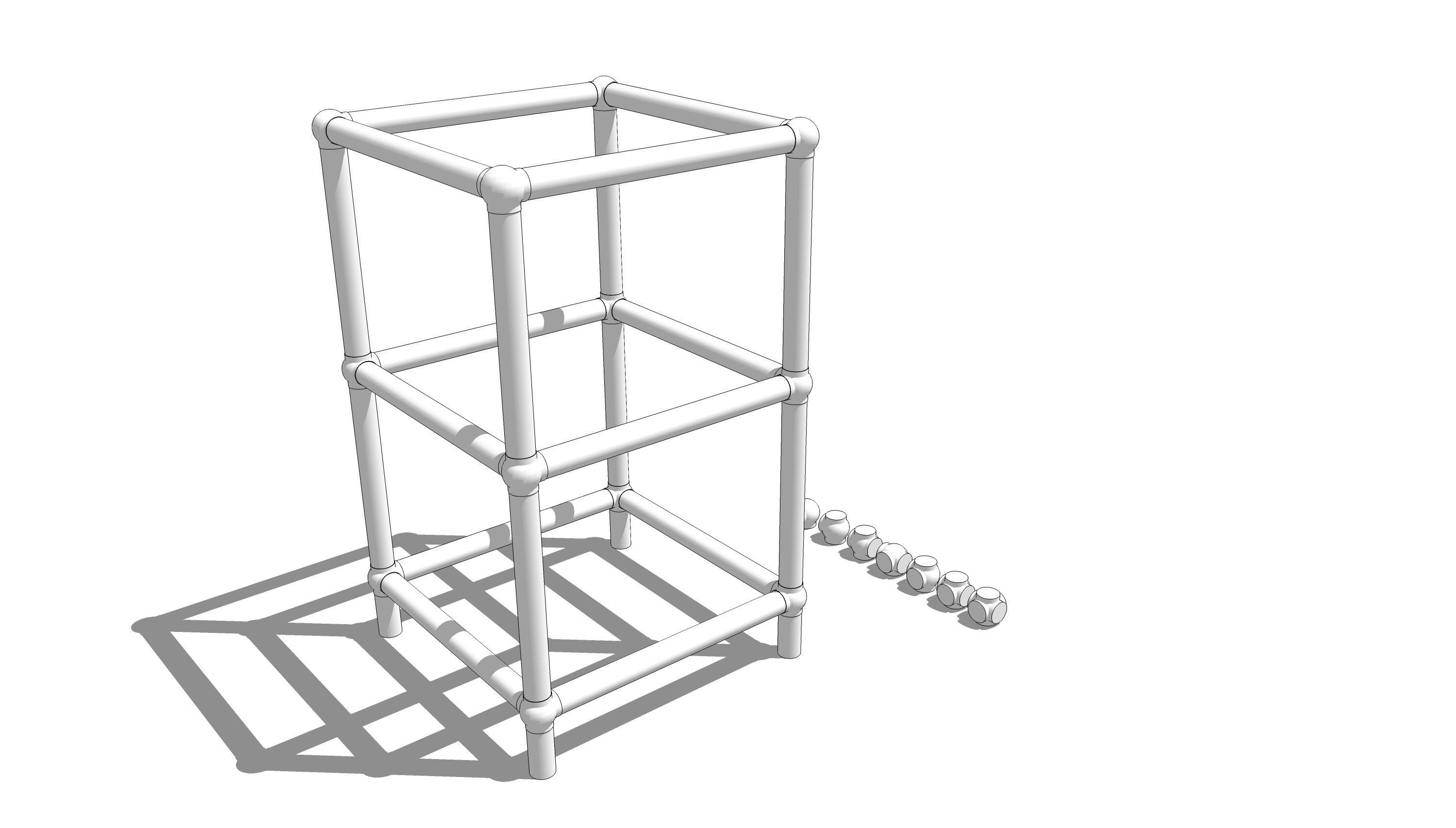

Here's a quick frame. All the tubes are the same except the feet. By the way, the tubes I drew are really cylinders. If you won't see the insides of the tubes there's no reason to have inside walls and the associated file bloat.

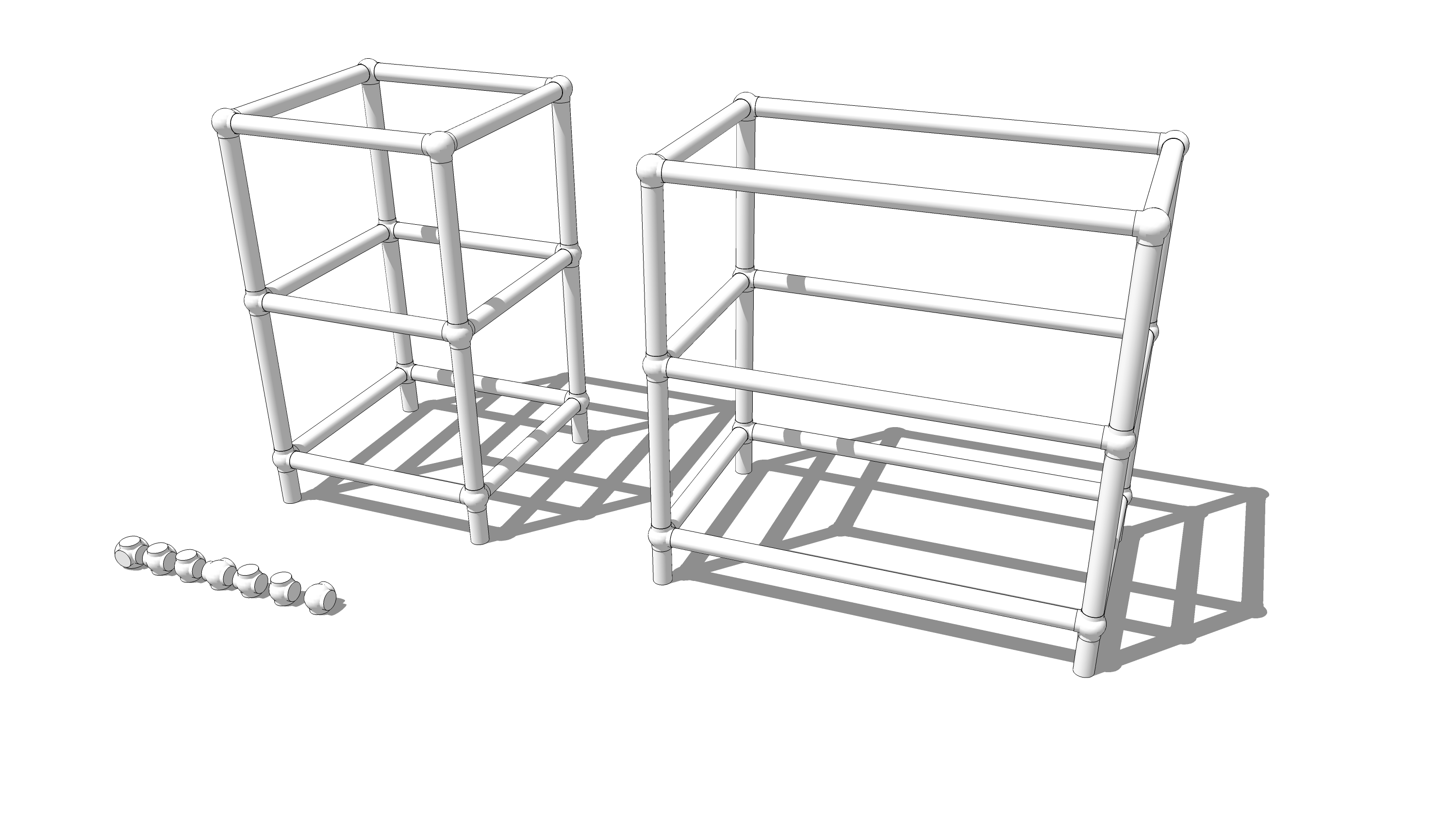

And here I've made a longer version of the frame. I simply moved the right end frame work over 6 inches and then extended the length of the front and back tubes. they are all copies of the same component so I only needed to change the length of one of them to have that carry through.Although the joints are nested components, the frames aren't nested in this case and they were easy to handle, you could do something like make a nested component of an end frame, copy and flip it to make the opposite end. Note flipping is NOT rotating. You won't want to rotate the copy of the end for this sort of thing.

I feel a bit sheepish sending you to another tutorial I did but take a look at this link. there's a video demonstrating how I converted a little fern stand into a hall bench.

By the way, I didn't use any plugins in the making of the example for these images here.

-

Great model there Dave! Well done,

Chris

-

Thank you sir.

-

Thanks Dave, this is really helpful. I will reserve any further questions until I check out all of the recommended tutorials and try to replicate your experiment. I really appreciate the effort.

-

You're welcome. If you want something to play with, here's the model I made. It's quick and dirty.

-

In general the alignment will require a translation and two rotations. You have speciacl case with the way the two axies are aligned ( and their circular symmetry) and where the components axis are place . Slelect the short tube start move and type [0,0,0]. That will move it to the 0,0,0 global axis location installed as Dave shows shows above

Advertisement