Anchor point when pasting

-

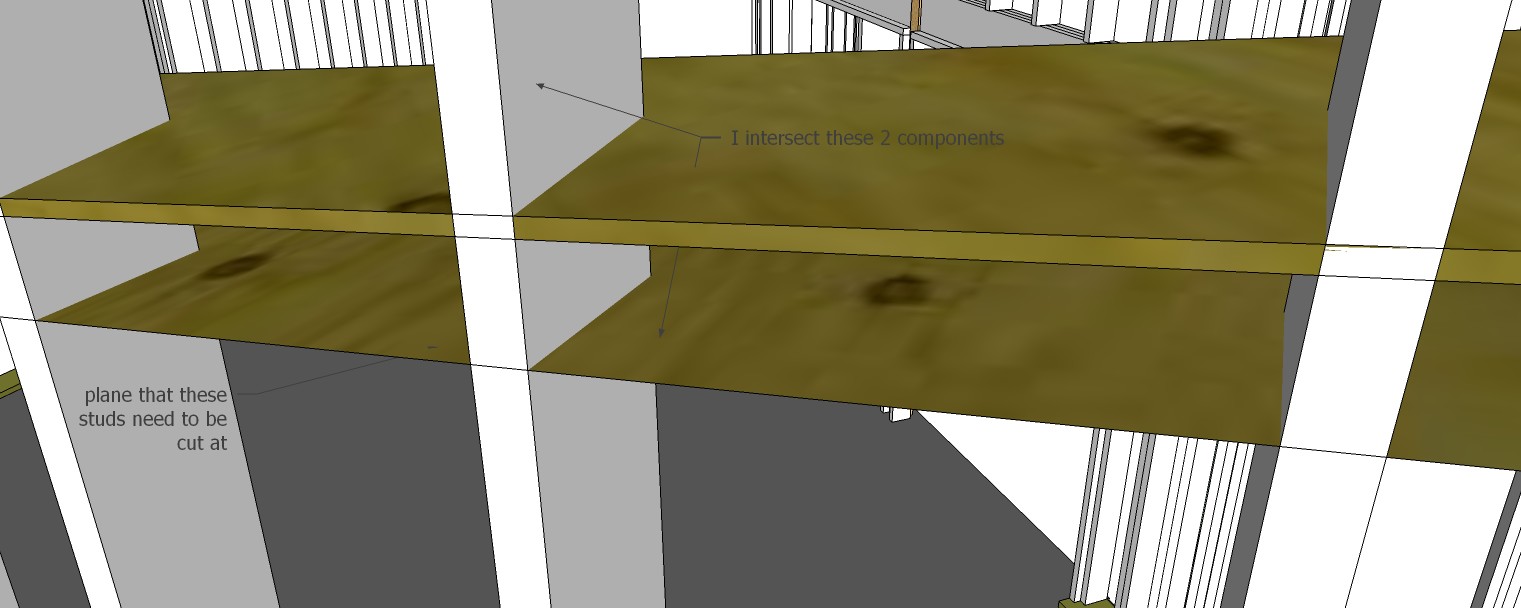

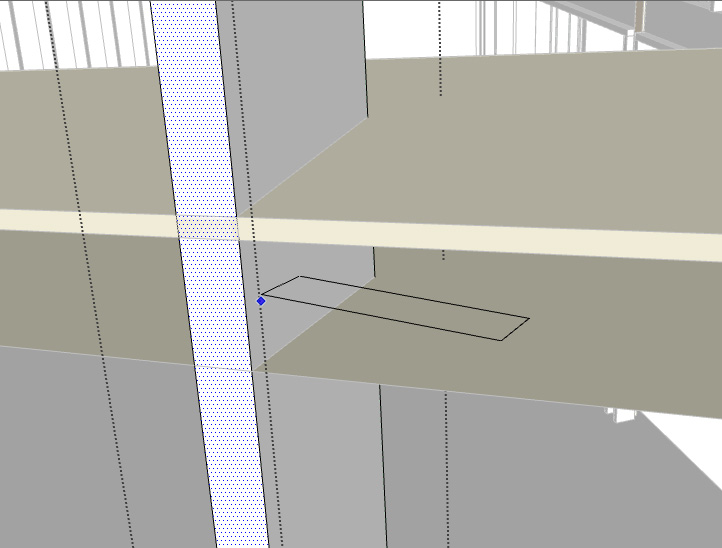

This is not exactly a step by step but shows the essence of the issue. First I intersect the 2 components, select the resulting geometry and copy it, then open up the stud component to paste and the geometry and it is oriented differently.

I do know that I can "paste in place" and it works for the first instance. But I have many of these operations to do and would like to not have to to the intersect step for each one. If I could go into each stud and hit paste then drop it where I need it would make the process faster.

-

Could you at least post the SKP of the studs and the two components with the plywood texture? I've been trying to understand what exactly the problem is but I'm still not clear on it.

-

-

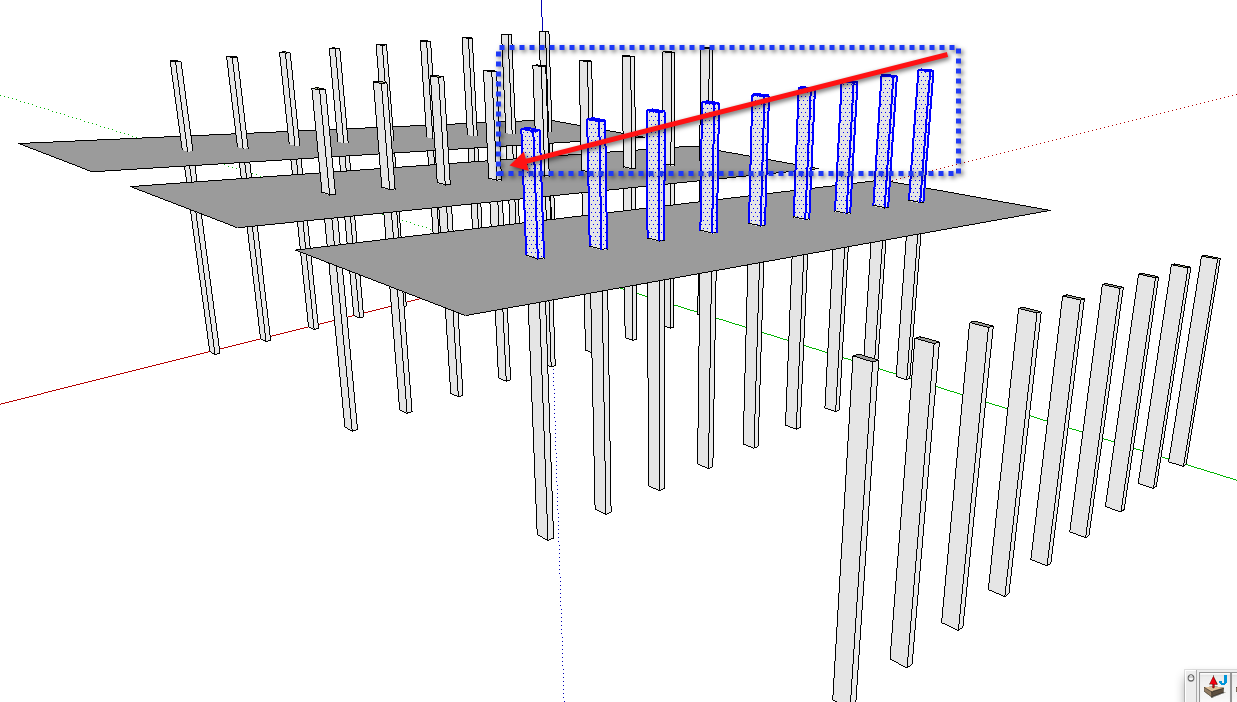

So do you just want to cut the studs off at the angle of that group painted with the plywood texture? (They aren't components, by the way.)

-

Yes, I am trying to find the most efficient way to do that. I am hoping to find a way to avoid having to intersect each stud since the angle for each wall is the same, it is just the height that changes.

I do realize that the studs are groups not components since each is unique. I was using the terms interchangeably in the beginning, sorry if that was confusing.

-

I think I would have approached it differently from the beginning. I'd cut one stud off at the right angle and then copy it to the other positions and edit each one to adjust the length as needed. Another option might be to use the Zorro plugin.

The component/group differentiation is important so I'd be careful using the terms interchangeably.

-

It's certainly not the most efficient way to model it but since you've got that far with it,

Extend the ply cutting plane out so it encompassed the whole stud, then open each stud and select all of it then intersect it.

This will give you the geometry you are after within the stud and you can select and delete the rest of the stud.

It's repetitious but you don't need to try inserting the geometry into each one. -

John's suggestion makes good sense and since you are this far in, you might as well just get to it.

-

I could see how that would also work. I think the speed would be about the same but good to think of different ways to skin a cat. Part of my asking is not just about this task but to look for a deeper understanding of how Sketchup works and how to be more efficient.

I seem to have figured out how to grab the geometry by a particular point when pasting (original question) but then saw it flipping 90 degrees when pasting inside a group which surprised me (still does).

Thank you for your input.

-

If you are looking for efficiency, your process of copying and pasting ain't it. Either John's suggestion of opening each stud group one at a time and running Intersect Faces or cutting one, copying it and adjusting the copy's length are going to be more efficient. It certainly is a good idea to sort that kind of thing out before you have to do it on another model.

An alternative for the future might be to avoid making the studs groups or components until after they've been cut. Just make sure they aren't connected to other loose geometry. Then you can do the intersecting of all of the studs at once and if you handle it correctly, you could even delete the waste ends in one go. then make each one a group or component.

-

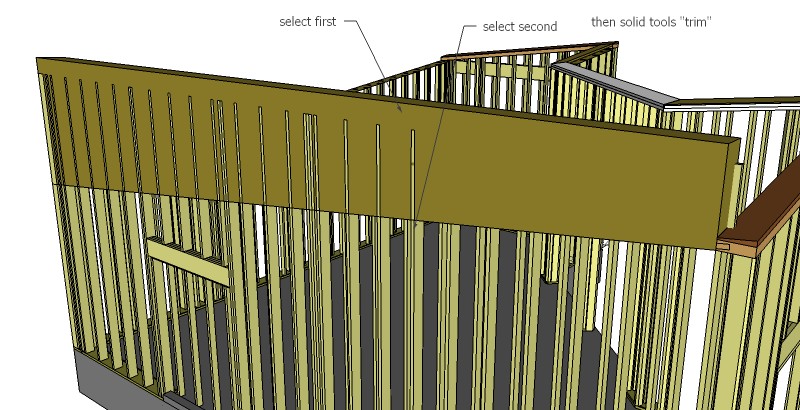

I found a nice solution to this which is very quick. Changing the group which represented the cutting plane into a solid allows the use of the new solid tools (first time I have ever used them). First selecting the group that will cut away the stud, then selecting the stud and then solid tools->Trim gives the result I was looking for. Pretty slick.

Thought I would share in case anyone else found a use for this.

-

Oh wow this is even better. First I select the cutting group then trim and it prompts me for the object to trim. Selecting the stud cuts that stud. If you wait for a second it prompts for the next object so I can just go down the line.

I will be checking out these solid tools more, this is fantastic.

-

Well, shoot! I'd have suggested using the Solid tools from the get go but your profile indicates you're using V6.

Lots of wasted time on this one.

Lots of wasted time on this one. -

Certainly sorry to have wasted anyone's time. I don't use the forums all that much and it never dawned on me to update it. I will update now.

-

It was your time that was wasted as well.

-

jeez, sorry to not be a forum regular and be aware of the proper etiquette. I set up membership a long time ago and had no idea the version I used was even in my profile. Since you pointed it out I see it and have updated it.

I am sorry you feel like you "wasted" your time. I thought this would be a good place to post a question about something I was having trouble with to people who felt like helping to whatever degree they were interested. That seemed like the case a while ago when I was using Sketchup and these forums more. I don't feel like I wasted my time, I learn from trial and error and now I know more than when I started about sketchup and this forum.

-

No wasted time that's a very good explanation of cutting a group I've forgot to up date my profile as well. I was curious why did you use groups rather than components and why did you not use sections to do that. May help me in doing that.

-

Where in New Mexico. Are you from or living.

-

@mwm: In my workflow I group/component everything that is a physically distinct object for the most part. I feel like it makes the model behave more like a real world object and is easier to edit. I do not use any geometry that is not in a group or component because it always seems to create way too many problems when I move or alter things. I use components for anything that is identical or symmetrical so I only need to modify one of them or one side of it. In this case each stud is unique so I use groups. This way if I duplicate a stud and alter one of them later they both don't change. I use layers for assemblies that are related (wall framing, roof framing, wall skin, windows and doors etc)

I use sections seldomly since SU doesn't render solids I find them to be of limited use for my work. In this case I am modeling the walls due to the complexity of the angles involved. I have a 5 man crew at the moment and If I can give them a plan with the angles and lengths called out it makes the work much quicker.

I am in Taos

Advertisement