[Plugin]Hole on Solid tool v1.6.3 upadate Jan 09, 2012

-

@guanjin said:

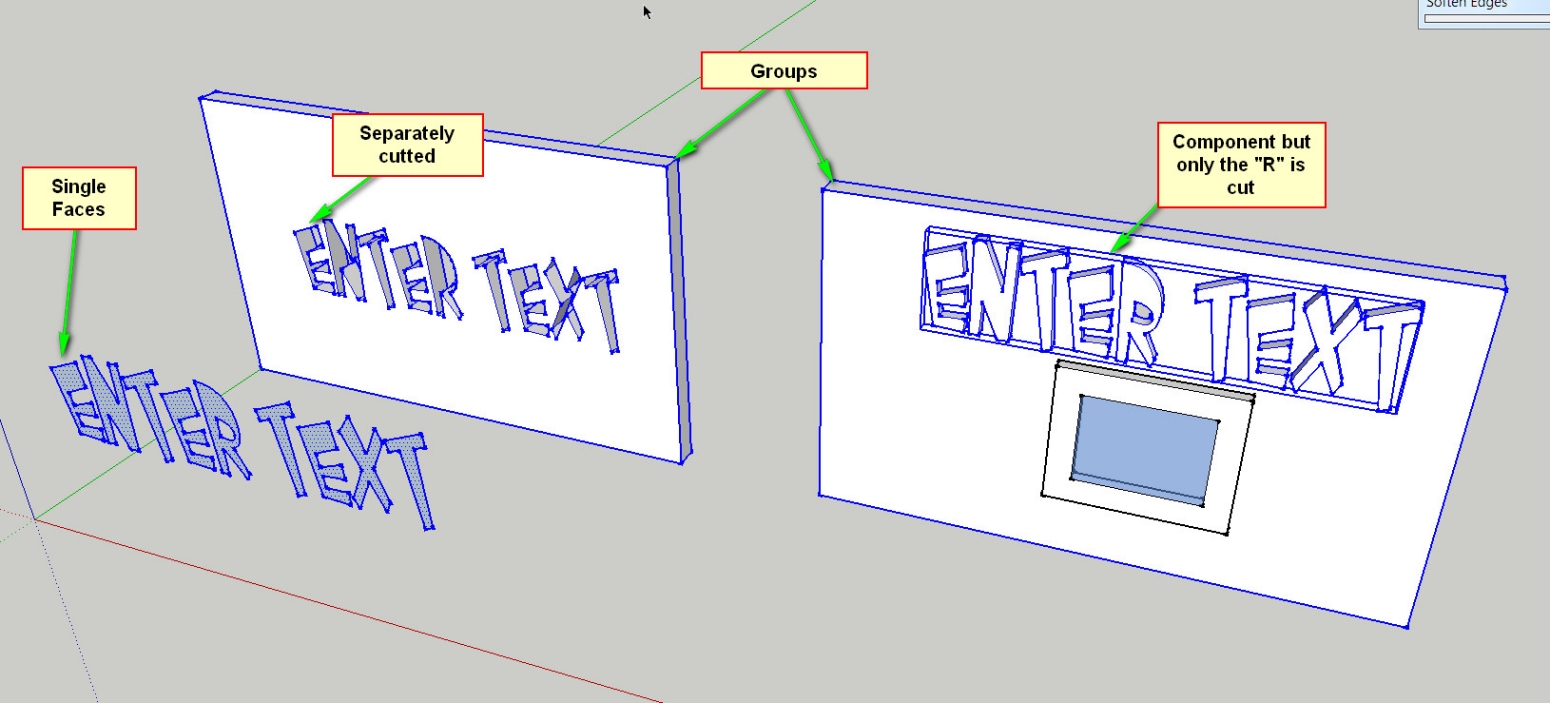

Creating the Component Selection cutting openings, holes can not be achieved? ? ?

[attachment=1:1jixhd7j]<!-- ia1 -->rrrrrrrr.gif<!-- ia1 -->[/attachment:1jixhd7j]Hi,XIAOLONG.

Outline for cut openning must be drawn on X-Y Plane( Red and Green axis).

When the component is already existed,You rotate axis in that component.

And outline must be placed in the root of that component.

[attachment=0:1jixhd7j]<!-- ia0 -->outline_must_be_on_xyplane.jpg<!-- ia0 -->[/attachment:1jixhd7j]

Watch for reference to create cut openning option.

http://youtu.be/0g6irIj---w

[flash=640,480:1jixhd7j]http://www.youtube.com/v/0g6irIj---w[/flash:1jixhd7j]Thanks.

-

@tak2hata said:

@guanjin said:

Creating the Component Selection cutting openings, holes can not be achieved? ? ?

[attachment=2:24c8pe63]<!-- ia2 -->rrrrrrrr.gif<!-- ia2 -->[/attachment:24c8pe63]Hi,XIAOLONG.

Outline for cut openning must be drawn on X-Y Plane( Red and Green axis).

When the component is already existed,You rotate axis in that component.

And outline must be placed in the root of that component.

[attachment=1:24c8pe63]<!-- ia1 -->outline_must_be_on_xyplane.jpg<!-- ia1 -->[/attachment:24c8pe63]

Watch for reference to create cut openning option.

http://youtu.be/0g6irIj---w

Thanks.Thank you! Have learned to see demo:

[attachment=0:24c8pe63]<!-- ia0 -->LLLLL.gif<!-- ia0 -->[/attachment:24c8pe63]

-

Hello tak2hata,

Your tool is impressive. I've done some experiments with it. It works really well. One question I have is it possible a component that contains some single solids to cut completely into the wall.

Charly

-

Hi,everyone.

I update in jan 09,2012.

Its version is 1.63.Bug fix.The hole from polygon mades smoothed side faces. it's improved.

I found from dave's post,and irwanwr's message.

Thanks. Dave and irwanwr.Hi,Charly2008.

That problem is not solved yet.

I will improve it,when I find the solution in future.

Thanks. -

hi tak2hata,

thank you thank you very much for your generosity

thank you thank you very much for your generosity -

@tak2hata said:

Hi,Charly2008.

That problem is not solved yet.

I will improve it,when I find the solution in future.

Thanks.thank you very much for your answer

Charly

-

Thank you. Excellency update.

Only a small error.

It does not work the command "Ctrl + Z". deleted one by one holes -

Great plug in

an option to set the depth of the hole would be great...

-

-

@jorge2011 said:

tak2hata

See litle fix.you can fix that?

Thank you very muchjorge2011.....

I try your model.

And I move the face for hole to very small distance.It succeed.The hidden line in the curved face is intersected with the hole on touch.

I will inquire about it.

Thanks. -

Hi-

I've installed the 1.6.3 plugin, but when I first re-opened SU the little Hole on Solid toolbox was "in my way" so I closed it -- now I can't figure out how to get it back. I can choose the plugin from the Plugin menu and it works to make single holes, but I've no menu access to the Multi-Hole variant of the tool, and no obvious way to re-open the toolbox...

Any ideas?

Thanks, -carl-

(SU8 amateur, MacOS 10.5.8)

-

Menu > View > Toolbars > the_Tool's_Name

On a MAC it might be called something like'Tool-Palettes'? -

@tig said:

Menu > View > Toolbars > the_Tool's_Name

On a MAC it might be called something like'Tool-Palettes'?Doh!

View>Tool Palettes

And there's your 2D tools palette as well.

Thanks, -carl-

-

@tak2hata said:

The face and solid must be in same Group or Component or Model.

And ComponentInstance for hole must have hole option.

It is rule of this plugin.Sorry newbie question - It took me a few hours (OK I'm really slow) to realize that the face could NOT be part of the solid. I'm having a couple of problems (1) creating the face - every-time I attempt to create the face it becomes part of the solid (2) I copied in a test object for the face but I cannot get it accurately positioned. Example I'm drawing a woodworking object and I need to have the hold precisely positioned and sized.

I've got to study a bit more to fully understand your statement in the above quote. If you have a reference video to explain what you have in the quote, for me that would be super helpful.

The concept is super and in the example file I downloaded it works GREAT! I'm using SU 8.

-

Could you post a screen shot of your model? Or better, the SKP file? It would be more helpful to explain how to position the hole where you want it and to sort out why the face becomes part of the solid.

-

Just discovered this plugin. Installed it and tested it with faces and components including multiple selections and it works like a charm. Thanks! It will come in very handy for window openings.

-

Very nice! It´s going to be amazingly useful

-

Once I click on the Hole on solid button I cannot selet the items. The selection arrow is shown but nothing gets highlighted or selected upon clicking. SU version Im using is 8.1.16.

-

@cjc0306 said:

Once I click on the Hole on solid button I cannot selet the items. The selection arrow is shown but nothing gets highlighted or selected upon clicking. SU version Im using is 8.1.16.

Hi,cjc0306.

That flow of tool is like this.

Start this tool.

Click Group/Component.

Click face for hole.

I think you selected face first?Thanks.

-

excellent tool tak2hata! I will be using this ALL the time

Advertisement