From SketchUp to Reality

-

But the nice thing about being able to model is that you can keep refining the design process as you do the grunt work. So, we were busy working out what the kitchen was going to be like.

So back to SketchUp.

and over to Thea for some visuals.

-

Dale,

Following this great thread as it is very interesting and informative. My favorite part is the two pictures of the Juncos! Most would not bother, but you chose to be a steward of your environment and friend of nature. Great to see this!

Dean

-

Dale:

In one of your early posts you mention that the ICFs are 4" of foam on one side, 2" on the other, which would give a reasonably insulated wall. (My pet peeve is the extremism of some folks in massively insulating walls/roofs, where they have long reached the point of diminishing returns compared to improving windows or some other system in the design.) Looking at the picture of the cat nearly hitting your wall, the inside and outside foam layers look the same thickness. Is this an illusion, or are both the inner and outer layers at this point 2" (or 4")?Compared to your situation, we didn't hit a single rock excavating for our house. We're on a mesa (I'm in New Mexico) whose what I'm told is called Aeolian - it's very dense sand deposited over a long period of time by the wind. It's very stable - you can dig a five foot deep trench with straight walls and it requires no shoring. (That's a practical statement, not a matter of safety practice. ) In digging our foundations (42" deep, 3' wide), we didn't encounter a single rock!

-

Dale, this is getting more interesting with each episode you post and turning into a Master Class. We are all following. BTW, did you model the bird house in SketchUp .... you will now have to keep us updated on the fledglings progress also.

-

@llaves said:

Dale:

In one of your early posts you mention that the ICFs are 4" of foam on one side, 2" on the other, which would give a reasonably insulated wall. (My pet peeve is the extremism of some folks in massively insulating walls/roofs, where they have long reached the point of diminishing returns compared to improving windows or some other system in the design.) Looking at the picture of the cat nearly hitting your wall, the inside and outside foam layers look the same thickness. Is this an illusion, or are both the inner and outer layers at this point 2" (or 4")?Compared to your situation, we didn't hit a single rock excavating for our house. We're on a mesa (I'm in New Mexico) whose what I'm told is called Aeolian - it's very dense sand deposited over a long period of time by the wind. It's very stable - you can dig a five foot deep trench with straight walls and it requires no shoring. (That's a practical statement, not a matter of safety practice. ) In digging our foundations (42" deep, 3' wide), we didn't encounter a single rock!

llaves.

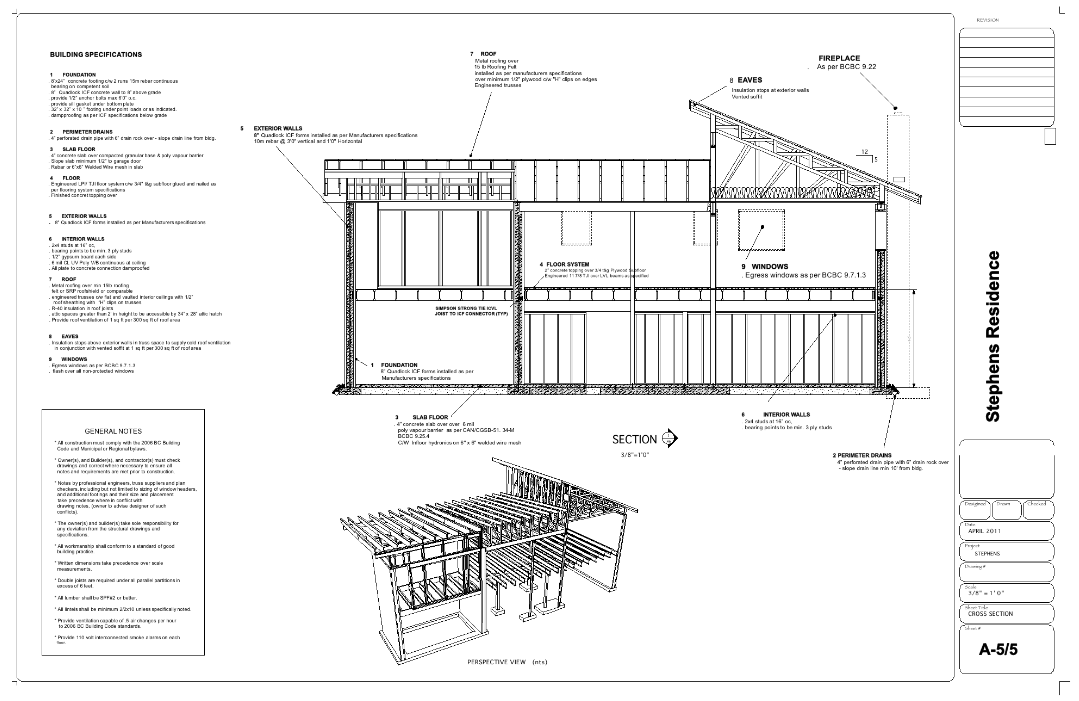

Ours is 2" and 2" styrofoam with 8" concrete. I probably should have found that particular visual, as I just quickly pulled this one off the Quadlock website.

Although we get some extreme temperatures here (-40 F ) they seldom last for long.

When we did the heat loss calculations I did as you said, and looked at a cost/performance comparison. I also had a long talk with my contact at Quadlock, who is kind of a roving teacher, technician, and he advised that he uses the 4" combinations only when the temperatures get down really low for extended periods.

I have used 4"/8"/4" combination on the community hall in town here. On that building we were originally going for a Leed Standard, and the heating system is employing waste heat from the Ice Arena next door to it so we wanted to have really high insulation standards.

They are just completing the Ice arena connection now, so it will be interesting to get to see how it performs.

As for windows, I totally agree.We have gone with Low E, argon filled with superspacer. Again we opted out of triple glaze, as the cost performance projection just didn't seem worth it.I envy your rock situation. We have some the size of volkswagens.

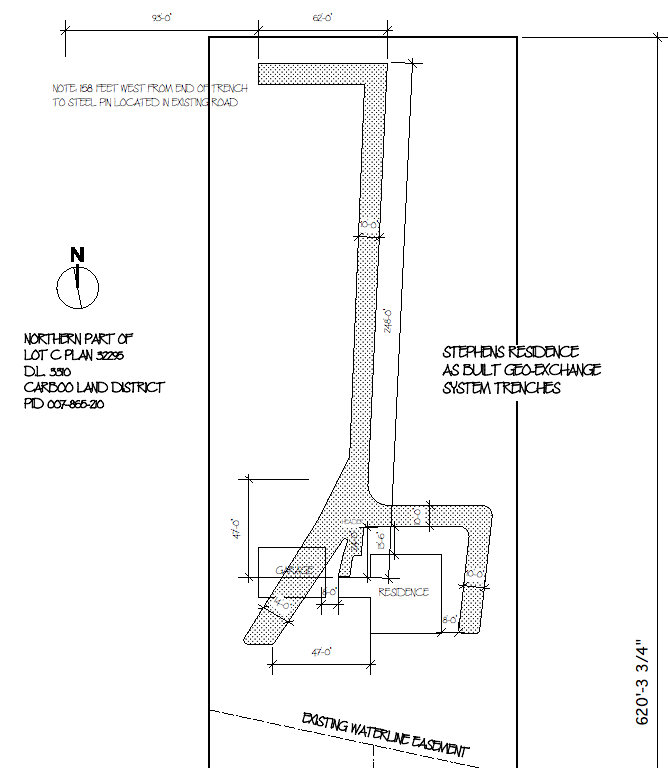

When the fellow who owns the property next to ours saw our geo-exchange ground loops, he decided to go with it as well. When he dug he hit all clay, and in 1600 feet of trench hit 3 rocks. -

@mike lucey said:

Dale, this is getting more interesting with each episode you post and turning into a Master Class. We are all following. BTW, did you model the bird house in SketchUp .... you will now have to keep us updated on the fledglings progress also.

Mike

As I said I am a little behind on posting this as in reality we are just finishing framing, so I can tell you the Juncos were a real riot.

When they fledged, they moved in under a pallet of peel and stick roofing underlay, and since they are seed eater, kind of ground birds, they were constantly darting around the jobsite. -

In reality, I can't wait to get to the cabinetmaking part of the project, as this is my favourite thing in all the building process, but....

There is in fact the real "reality" .....

So the underground servicing goes in so that we can insulate the slab for infloor hydronics.

This is code here to have a minimum of R-12 under a heated slab. We have 2" foam which gives us R-14 mostly because R-12 is hard to get.

We also used this as a vapour barrier, and Judy tuck taped all the joints with connection to the Quadlock.

Then we added the 6X6 (152.4 X 152.4 mm )welded wire mesh, and were ready to pour.

-

There is a community of Mennonites here, all of which are meticulous hard workers.

We subbed the concrete placement and finishing out to them.

The last photo shows the hydronic pipes tied to the 6x6 mesh. The Geo-exchange system requires shorter loops, an maximum of 200'(61 m), and a 6" centre from pipe to pipe.

This is apparently because the system is more efficient if the water is returned at a slightly higher temperature.

We have done many water based Geo-exchange system, but this is my first ground based system, so I'm asking lots of questions, and generally being a pest.

-

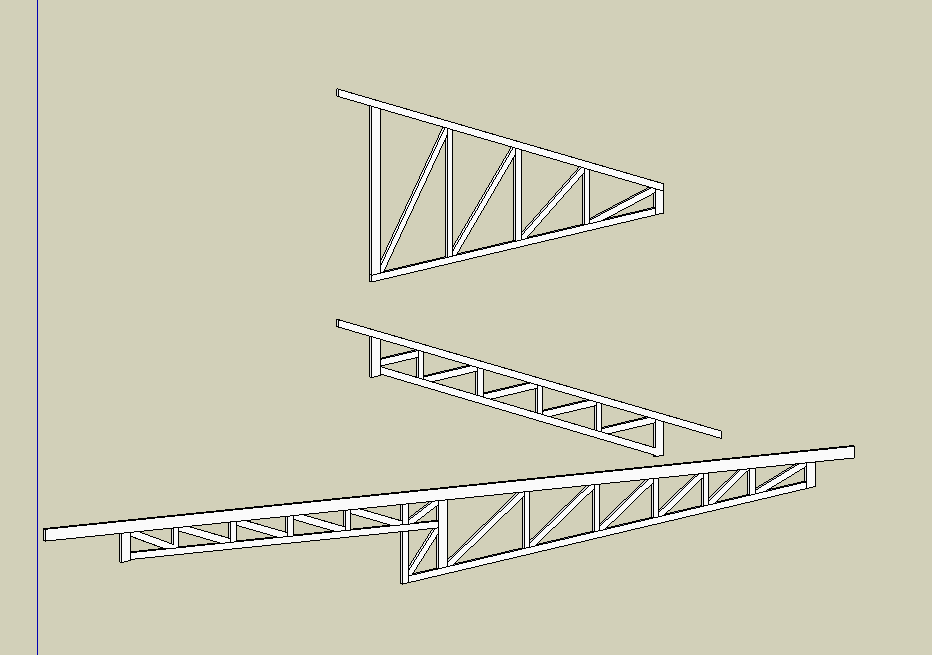

Then on to trusses.

I was pretty specific about the style of trusses I wanted, as we had a few details we wanted to include, like extending overhangs of the lower chord so that it would act as a valance for potlights, and just internal ceiling shapes and heights.

Again SketchUp is just so easy to get your communications across.

I even convinced the tech to down load the free version so he could pull measurements, and walked him through the basics. Needless to say he was pretty impressed.

Living room trusses on LVL Beam

Framing the lookouts.

-

very tidy and clean all the process

huge job -

Juan

Thank you a very appreciated comment from you.Dale

-

Great stuff Dale.

Some complex trusses there especially the sloping one over the ??? room. I imagine the void will be useful for services.

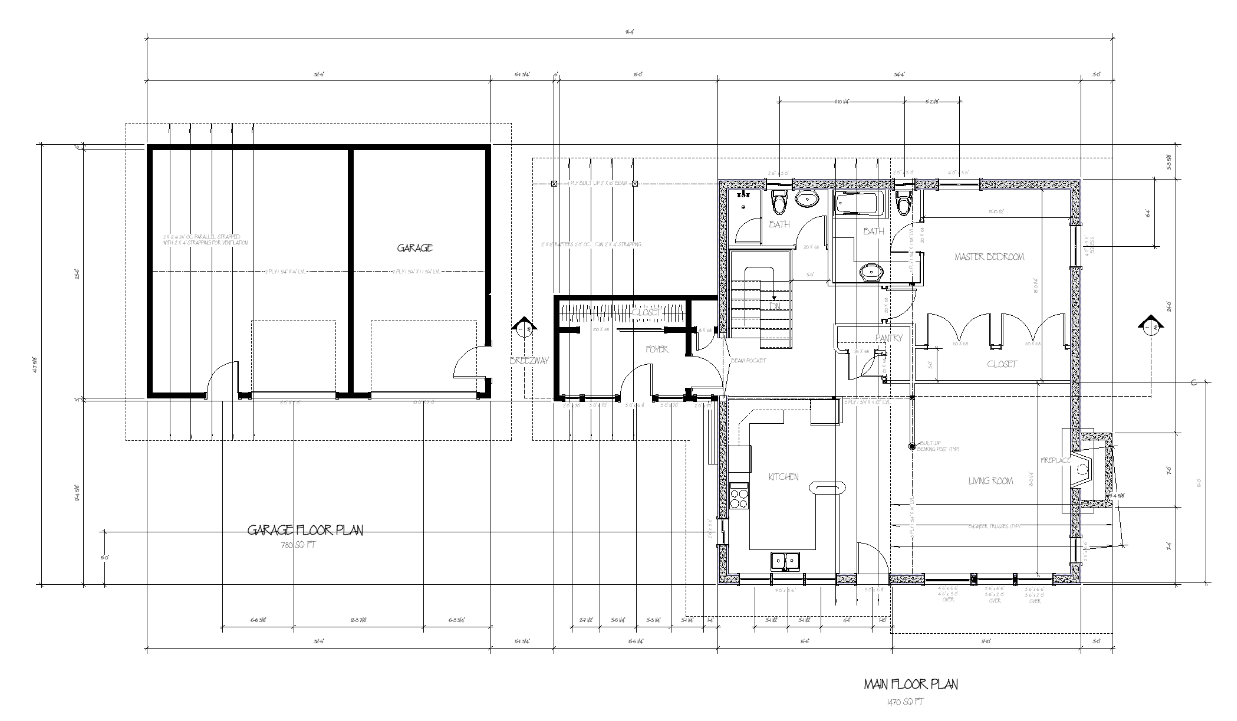

Is there any chance we could have a look at the plan layout so we can get a good overview?

Mike

-

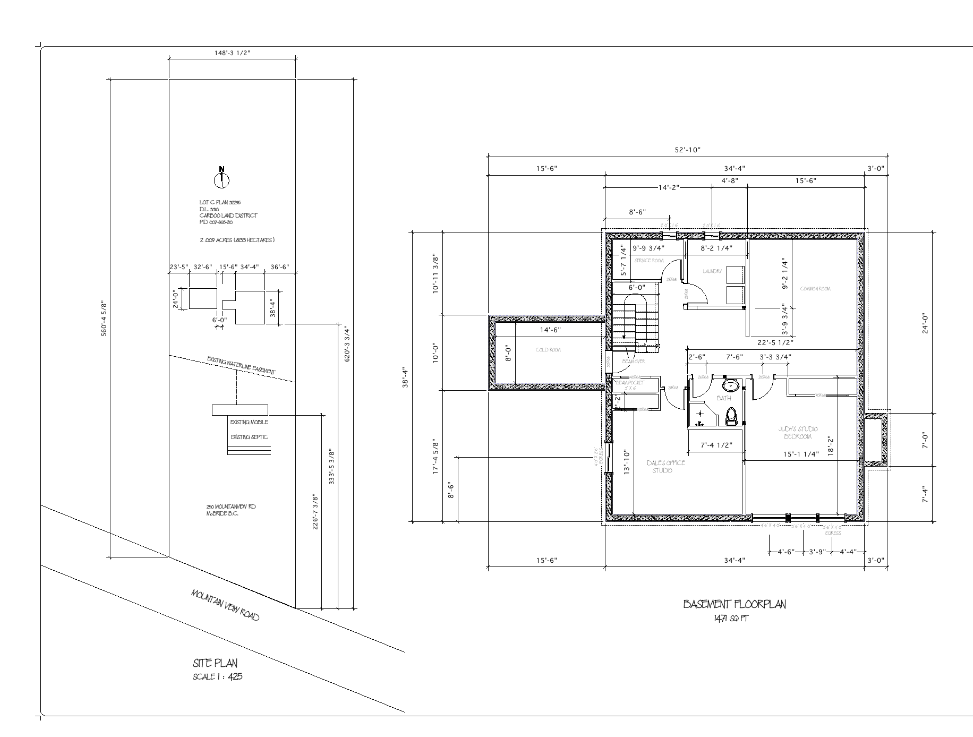

Hi Mike

Here are the floor plans for the main and the lower floor and a section.

Really crazy here right now so I will post some more shortly.

Cheers

Dale

-

This is a hijack your own post notification:

As an aside to my own house project, another project on the books just had a grand opening.

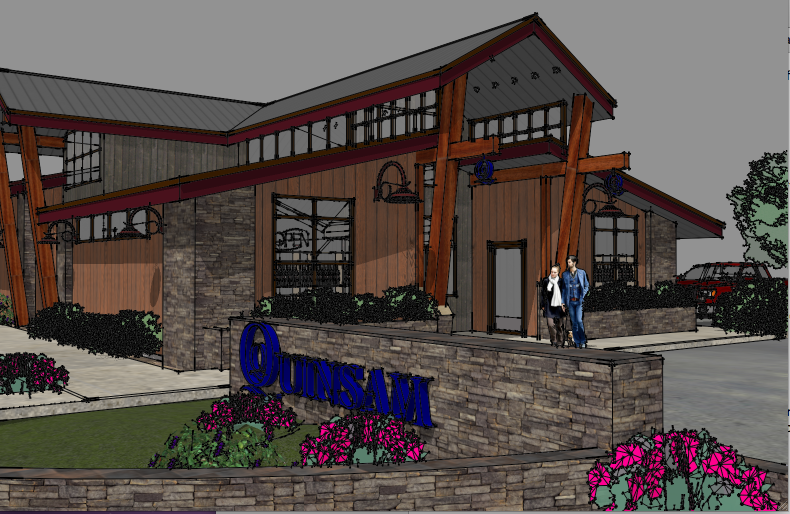

This to was a from SketchUp to reality project, so I decided to include it as an aside.the SketchUp model:

The rendering:

Reality:

Opening ceremonies ribbon in place:

Interior Clerestory

-

Thanks for posting your house plans Dale. The layout works well. The house looks to be designed for two to three residents? BTW, I will be using your semi-circle direction line (on half landing) in my stairs plan in future

-

Yes Mike it is built for Judy and I, and the studios double as guest rooms. The design is very personal combining things we have liked about our previous residences.

I think it is harder in a way to design your own project.

We have also made it so that we can live entirely on the main floor should the time come that we have problems with stairs by doing things like roughing in plumbing in the little pantry area. -

The ground source Geo-exchange system was a big project.

We put in 1800 lineal feet (548 m) which required us to dig trenches about 6'(1.8 m) deep x 10'(3 m)

The headers were fused chemically fused to the pipes for the two trenches. When we buried them they were separated by about 2'.

-

Hey Dale, Do you guys sweep the ground before taking the pictures? Everything is so neat and tidy

I'm very interested in learning how the geothermal system works out. I have never (yet) been involved in an install.

I have a similar layout in my humble abode. We (Pauline and I) could live on one floor if the need arose. However I would have to do a major tidy up of all my bits and pieces

Mike

-

Hi Mike

This is the first Geo-exchange system that I have owned, so I am very interested in how it performs.

At work we have had several projects with water based Geo-exchange systems and all of the owners are quite happy with them.

This system is based on a three ton unit, with 4 ton of capacity of buried pipe.

I have had quite a few discussions with their engineer, and he said the main thing in the hydronic system is to go with shorter loops, and return the water at a slightly higher temperature, which in turn raises the efficiency of the system.

In the above picture we are carrying in the supplementary storage tank which has a 4.5 Kw capacity to assist the system if it is taxed.

We can get down to -40 here, but it usually doesn't last for long, and this house is built around mass, but we are designed to supply both heat and hot water.

As for the cleanliness, it sure doesn't seem like that to us.

It feels like chaos. -

I just across this post. I have been looking at house planning for a while. I thought I did a good job on the house I am currently in. However, I found out I was terribly wrong. About 8 years I awoke to a slight twitch in my right cheek. I eventually found out I have a rare neurological disease. I am now confined to a powerchair. Looking at my house today it would have been easy to make it handicap friendly. I could have added a role in shower for almost no cost difference. I could have put 6' x 6' closets on the first and second floor that line up. This way installing an elevator would be simple. I could have made all internal doors 36". There are lots of other items I could have done to make my life easier. It is not something you want to plan for but it is something to consider.

Advertisement