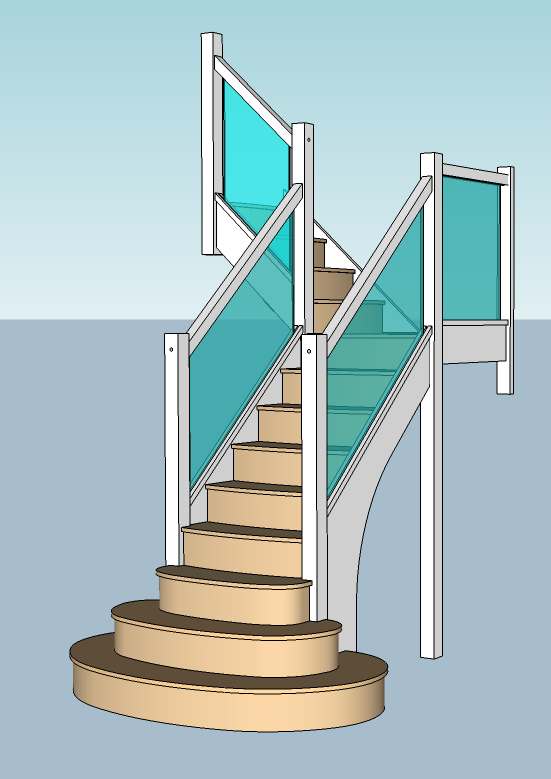

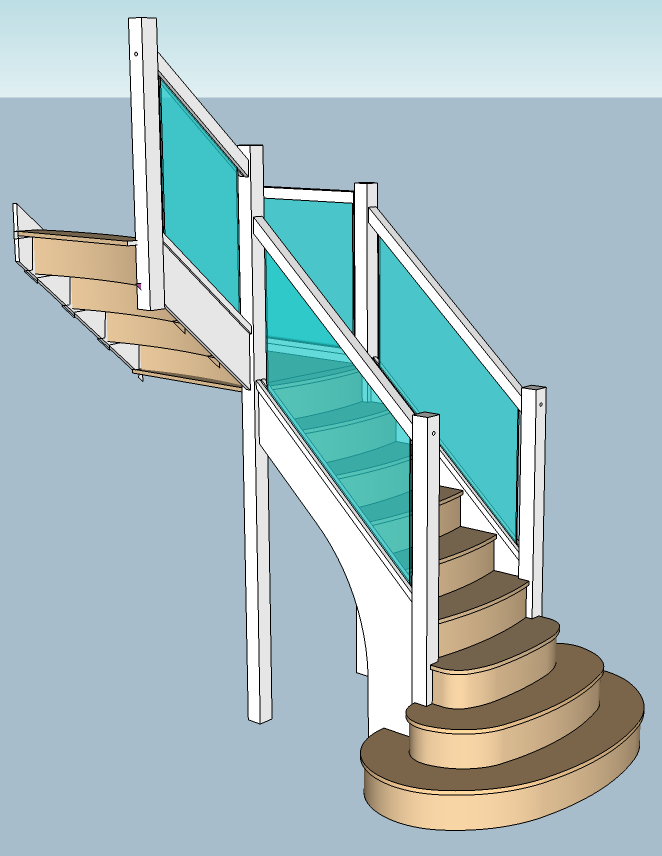

Oak Bow fronted staircase with joinery modeled.

-

Hey,

Just a quick one, I just finished a model for a staircase we are making, most of the joinery is modeled.

3d warehouse Link here http://sketchup.google.com/3dwarehouse/details?mid=dc88bcefb0c5d3be7b1616c6941a08f6

Everything will be made in american white oak, with Bow fronted treads (the bottom step is huge!) The balustrade is 10mm Toughened glass.

The staircase is currently in construction in our shop, so I will hopefully get some photos soon too!

Tom.

-

Interesting.

With the stringers be painted or will they also be oak? Will the glass be that color? How do you make the curved risers, especially for the bottom three steps?

-

The stringers will be in oak. (I just use white for some reason in my models!)

the glass will be clear.The bottom 3 steps have been manufactured, the main parts of the staircase have been manufactured, just need to assemble it now. will be sure to get some photos later today/tomorrow.

I use 10mm Oak faced MDF for the risers, with MDF formers behind. the risers have saw cuts in the back, in order to allow it to bend.

-

Do you use solely sketchup outputs for manufacturing your staircases or do you use any other software?

Realy nice pages of your firm and realy good work you are doing.

I was always wondering how do you make staircases. Can you post any photos from you workshop? -

Great little web site you got there.

I to am interested it the manufacturing process. I am assuming that you CNC every thing you can and the build what you can in the shop and then take it to be installed.

Looking forward to the pictures of the shop and install.

Cheers

S

-

^^

Agreed but if thats what the costumer wants then thats what they get.

-

If its to code then there should be no question.

-

Yep, to code, Of course you would make it shallower/bigger given enough room.

The only way that the bottom step would be a trip hazard is if there were a walkway/corridor on the right hand side of the staircase.

We have other software specific to making stairs, but for some jobs we use sketchup to get a decent visulisation of the stairs.

we cut everything we can on CNC Routers, for assembly in our shop, we do not do any site fitting work however, so we do not often see the finished product

although I'm sure we will see some photos of this in a month or so.

although I'm sure we will see some photos of this in a month or so. -

In the UK under the convoluted 'stair/guarding' regulations/standards you are allowed 600mm [old 24"] unguarded drop at the bottom of a domestic staircase [1/2/3 risers], or any other change in floor level: on other 'public' stairs the drop is limited to only 340mm [1/2 risers]... BUT there is now other legislation for 'public accessibility' which overrides this, so even that's rarely seen these days - now the bottom staircase handrail has to extend past the first step by 300mm and run horizontally at 1m above the floor [this is so semi-ambulant people - e.g. in a cast or leg-caliper - can steady themselves entering or leaving the flight] - so now there are no unguarded steps at all; also in trafficked areas at any other level change greater that a road-kerb height there needs to be a kerb-upstand/balustrade to stop wheelchairs running off etc.

-

yea the regs can be a headache

There are at least 3 pieces of software that I know of that carry the building codes for the uk - compass stair, staircon and alphastair.

-

England and Wales use 'Approved Document K' for stairs/guarding and 'M' for accessibility.

These in turn refer to a raft of BSs and CPs. You can even design the stair to the BSs and get slightly different results compared to Part K which are only 'deemed to satisfy' [e.g. for a helical/spiral flight]... -

Some pics of it in our shop... sorry about the guy posing!

Advertisement