Another "What is it?"

-

Here is another "What is it?" challenge. It is something I am currently working on and something some of you could use. You are free to ask for clues but not answers. In other words you need to specify the nature of the clue you are looking for.

-

Does it have anything to do with photography?

-

No, there is some shared technology and thinking, but we can safely say there are no cameras directly involved with this device.

-

I could blurt something out here based on previous dialogue.

-

Iphone5?

-

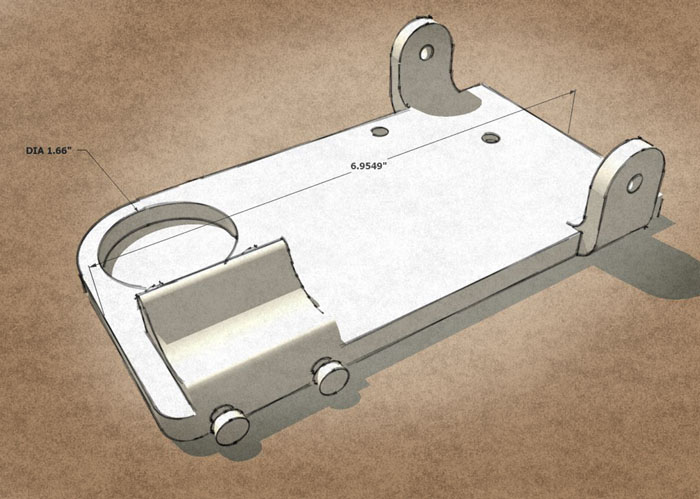

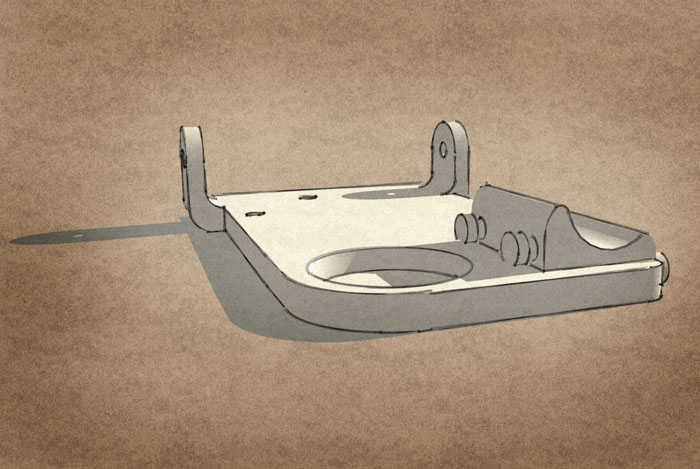

Another viewMitcorb, before blurting, describe the function of every design element.

-

Cup holder for a Hummer?

-

-

Is the saddle block(?) adjustable? Does it travel? What about the studs, do they advance/ recede? Do you intend this as a casting? But the spindle tabs suggest not.

-

-

@mitcorb said:

Is the saddle block(?) adjustable? Does it travel? What about the studs, do they advance/ recede? Do you intend this as a casting? But the spindle tabs suggest not.

Good beginning on the analysis. I think you would get me soon if you have not figured it out already.

The saddle block only travels if I have it in my car, but in relation to the rest of the gadget it does not travel. A small monocular sits in the saddle block. The studs are static. They serve as "hitching posts" for an elastomeric fastener (rubber band or one of those things that girls gather their hair with). The rubber-band-like thing wraps around the posts and over the monocular to keep it snug in the saddle block. The circular depression seats a round bubble level. The leftmost vertical hole in the front accepts a threaded nob that passes through the plate and into the bottom of a Bosch distance meter. The hole just to the right of that is for attaching the device to a tripod.The spindle tabs might be a bit over the top for what I want to achieve. However, they are there to accept a gimbal mount that positions its rotational axis so the laser beam would pass right through the center of rotation. I think they could be cast if they were solid and the spindle holes were drilled out in a separate operation. For now the object will be 3D printed as a one-off bespoke item.

Is there production demand for such an item? Something in the back of my mind says maybe/possibly but far from certain. Because of computers and other new technologies, I see a shift to decentralization and a shift to generalists over specialists. I think that the lowering price of electronics could put cheap but sophisticated measuring devices in the hands of people that could not afford accurate surveying equipment previously. I also see this kind of equipment lowering the costs of surveying and measuring while ensuring accuracy and speeding project completion. On the other hand surveying is an old and conservative profession that is licensed and often unionized so there is great resistance to change. However as low cost tools are accepted by estimators, renderers, archaeologists, some constructors we might see more people doing their own measuring and estimating work. For me, I get tired of trying to render from poorly measured and poorly conceived estimating sketches. As a renderer I spend too much time making things work and filling design gaps from rough conceptual drawing. In other words, the designer wants concept sketches when he or she is just throwing something at the client to see if they can get the project. That forces me to actually make up details that were not on the sketch from the back of the envelope. So I design without getting paid to design as opposed to working from real specifications. So I am at the point where it is more practical to take my own photos, visit sites, measure important details etc, so I am not guessing at everything. This is why this gadget is for me as a one off gizmo. Still I can see others with the need for version 2 or even version 200 of the same gadget.

Anyhow drawing to follow will demonstrate what I am up to.

-

This is more of a test bed than a production unit.

-

-

Hi, Roger:

I like your concept. I often catch myself analyzing products and seeing how to improve them. One of the things that tick me off in the area of product design is the fairly common misunderstanding of material properties. You buy some appliance made mostly out of plastic and some prominence or other is subjected in normal use to stresses that only steel or aluminum can really handle. On another note, after the wimpy supports and wheels on my Weber Kettle barbecue pit gave up, I took a burned out Sumbeam gas grill cart and married the two. In an over the top tour de force, I applied lawn mower wheels to the unit and scavenged some heavy duty casters from a moveable store display unit. The kettle was mounted to the cart with scraps of 16 ga. steel framing track. I call it Frankenstein. It's getting old. This was done two years before Weber came out with their own cart. Needless to say, I am not wealthy.

-

Another improvement I was thinking of was to replace the 1 milliwatt laser with a 10 Gigawatt laser. You would no longer have any problem knowing if the laser was properly targeted on sunny days. The smoke, fire and sparks would instantly let you know when you are on target.

-

I like your thinking on the laser upgrade

-

Mitcorb, (?German for I'm "Mit Corbusier?)I find it hard to believe there are any architects who are not wealthy.

-

Nothing so exotic on the name, just a differentiation. While I slept, Weber pushed my "necessity" into production.

-

So the monocular is just to check the aim of the laser? I have a Leica Disto D5. I have not used the red glasses much. The D5 has a digital viewer if you need it and that fits most situations. You can magnify the surface you are aiming at quite a bit, It has cross hairs etc. It also finds angles. It just takes a lot of practice to use the more complex measuring methods smoothly.

What I find challenging is finding grades, without going out and buying a transit of some sort or even a good level laser (capable of outdoor use). I have sometimes compelled my contractor friend to help me with his transit. The Disto isn't really suited. It tells you the angle you are tilting it but doesn't shoot an automatic level. The other trick to figure out is making and attaching targets for corners of buildings etc.

I too often need to get some designing done where a survey is not an option, but screwing up on grades and other measurements can cause problems or waste time.

-

@PBACOT

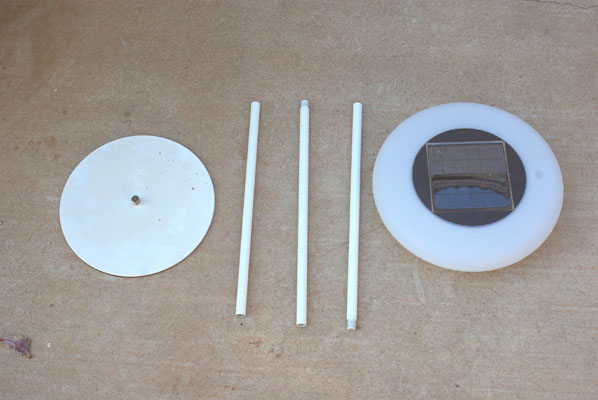

I was measuring the width of my house and here is what I used.

This is my magnetic target attached clinging to the upright of a solar lamp purchased from IKEA

Here is a close up so you can better see the laser dot. In real life the brightness range the eye accepts is much greater than what the camera accepts. So that laser dot is only slightly less bright than the spark from an arc welder.

Here is how the IKEA lampkit breaks down for travel. You can take along the lamp part or leave it at the office. In you have to work after dark or have an emercency it could come in handy.

See the second page of this post (http://forums.sketchucation.com/viewtopic.php?f=72&t=39083) to see how the laser target is assembled from neodymium magnets, foam tape, reflective tape, and a steel strip.

Advertisement