Dome Model In Reality

-

This is what this code checking software warns, but I still use it often.

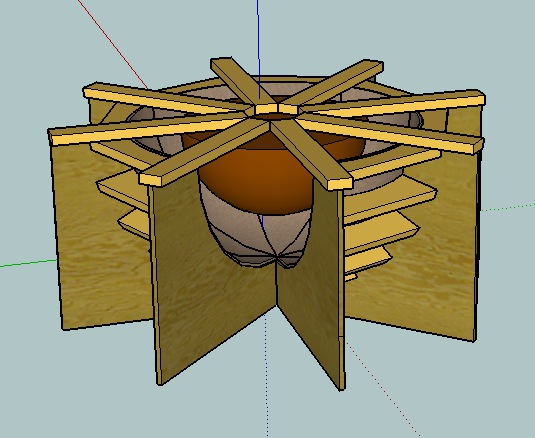

Acute angles will always be weak and prone to breaking off because the aggregate won't fit leaving just sand and cement (or equivalent). I suspect to make a bung in Sketchup, you would make a circular hole in the top of a dome where the circle on the outside was bigger than another on the inside - to get a bevel on the bung and the same on the edge - like a lid or large cork.

You might like to consider making the dome on a traditional sand mould and then cut it into segments (and bung!) before final set, if you want to transport and/or sell it like that.

-

Hi Chris

Thanks for the link. Quite helpful.

Sorry if these question may sound silly.

What do you mean by a beveled bung?

Could you explain more about acute angles?

With regards to the cast, how would you change the drawing I already have to easily make a mold that would be safe and not fall apart?I don't really have a business plan but before going to that step, I would first like to build my oven, use it, and see whether it warrants me to convert it into a business. I would hate to be optimistic and realize its not a viable option.

Thanks

Regards

D0me -

Hi Chris

Sorry, my understanding when it comes to these terminologies is poor to say the least.Never the less, I catch what you saying.

I did actually ask Gai to assist me in doing this but since we are gone so far in the model, I will attempt this when I redo the model as a means of exercise for myself.@unknownuser said:

You might like to consider making the dome on a traditional sand mould and then cut it into segments (and bung!) before final set, if you want to transport and/or sell it like that.

I understand the part about using a sand mould and then building on top and around it but how would I go about cutting it into segments and wouldn't that be time consuming compared to a mold whereby cement can be poured directly into it and I would have a ready piece of the mold. Only step left is to put the pieces together.

I'm just weighing my options against a mold.

P.S I will probably be moving this oven around alot so I would need something that would hold up to that.Gai: Chris has put my request in better words than I did. Can we incorporate what Chris suggested into our model.

Thanks

-

What I think would be good in pursuit of the caption is to make a contraption - a stick that is set in the sand mould. It has an arm for screeding the outer surface of the casting and something to cut the bung. There could also be templates for cutting doors and vent holes (needed by the way), and cutting wire for the segments.

Now I must get back to work!

-

Hi Chris

Sorry to keep you from your workI understand where you coming from.

Just out of interest, why did you set the caption "DOmes for developing countries"?Anyways, when you have some time, could you put your words into a picture. What I mean is if I see what you mean as an image or sketch, I could visualize this better and maybe will proceed further using this method.

Thanks so much for taking the time out to assist.

Sorry again for keeping you away from work.Thanks

Regards

D0me -

@d0me said:

Just out of interest, why did you set the caption "DOmes for developing countries"?

Just seeding ideas.

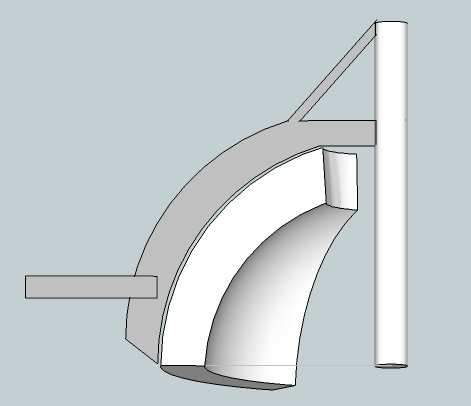

And here is a v rough sketch of a "spinner". It would need a big spigot at the base and the screeders (for sand mould, inner and outer domes) will need collars to spin around with the pipe. Another spinner would have a blade to cut the bung; another a collar with six wires to cut the segments. A circular baseboard would be needed with six slots in order to be able to cut through near the base.

Basic method:

Set up baseboard with spigot and pole.

Build up sand mould and screed.

Build up dome layers with stiff mix and screed.

Cut bunghole (sorry!).

Discard bung.

Cut segments.

Take out pole.

Fill in with sand.

Pour new bung + hand finish.or something like that.

-

Hi Chris

Thanks for that. I think we have something going here.

Sounds like a plan to me.My apologies for the questions to follow. To be honest, some of the terms are gibberish to me but I more or less understand it in context so I'll try and re-iterate what you just said in my own way and please correct me if I am wrong.

- A Spigot - My understanding of this term after googling it, is a plug for the bung hole. I tried to find some pics of it but nothing really. Do you know of any? After reading further down the page, I notice u mentioned the spigot needs to be attached to the base board, so I'm little confused here.

- Screeders - From what I've read Here, a screeder is someone who levels and removes air bubbles from wet concrete.

- Collar - What sort of collar should I ask my hardware store for?

I got a good idea of what you have in mind, just need to get more detail on finer bits.

Gai: Is it possible for us to draw whatever Chris has mentioned, basically labeling each item so I can get a much better understanding of how this puzzle fits together.

By the way Chris, your idea is brilliant. It will save me money on creating a mold, as well as time and effort in learning how molds are created. As Jeff mentioned, you need to have experience with Complex Curved Construction. Maybe if this oven is a success and I do decide to go commercial, I can look at a mold at a later stage or just stick with this method, whichever works best.

Thanks

-

@d0me said:

Gai: Is it possible for us to draw whatever Chris has mentioned, basically labeling each item so I can get a much better understanding of how this puzzle fits together.

I would say anything could be possible - first at least one of us should understand what Chris is suggesting. I am definitely nor technically oriented enough to be sure that I get the idea...

-

Hi Gai

I'm not technically orientated either but because I have been researching this oven a bit, i can grasp a little of what Chris is saying.

Hopefully Chris and the guys here can detail this a bit more in simpler terms so we can put pen to paper or should I say Mouse to SU.

Thanks

Regards

D0me -

i don't get why you want to do it in 6 parts..

isn't the thing only 3 1/2' in diameter?make it one piece and you'll save a bunch of headaches in terms of sealing/joining/leaks etc.. you're going to need machinery to move six individual pieces so you might as well use that machine to carry only one piece and not have to worry so much about assembly.

-

i looked at the other thread and yeah, make it one piece..

if the dimensions are roughly 42" outside diameter and 7" thick then it's going to weigh ~1150 lbs...

one-sixth of that is 190lbs so you're still going to need a forklift..make it solid and you'll eliminate many problems.. not to mention crushed fingers..

-

@d0me said:

- A Spigot -

@d0me said:

- Screeders - From what I've read Here, a screeder is someone who levels and removes air bubbles from wet concrete.

Yes but I used the term for creating the surface geometry for any cast-able material. These non-human screeders here are curved and they need to be moved to create the curve on another axis curve - think

followme.@d0me said:

- Collar - What sort of collar should I ask my hardware store for?

A two piece pipe bracket or holderbat that can be clamped onto the pole at predetermined positions

-

@unknownuser said:

i looked at the other thread and yeah, make it one piece..

if the dimensions are roughly 42" outside diameter and 7" thick then it's going to weigh ~1150 lbs...

one-sixth of that is 190lbs so you're still going to need a forklift..make it solid and you'll eliminate many problems.. not to mention crushed fingers..

From what I understand from Gaieus' approach it is more important to follow the brief than specify the solution (from a learning viewpoint)

-

Well, it wasn't my approach - D0me wanted to model it that way. It would've been certainly easier to do it in one piece. Maybe the "sections" are only for the moulding?

-

if you're planning on making a few of these, you might want to go in this direction.. (if you want to make a whole bunch (15+), get a legit one made out of metal).

set that on a vibrating table or use a handheld vibrator (i like this project -- so far it incorporates vibrators and bungholes

)..

)..you'll need to incorporate something to hook cables onto the oven to pick it out of the mold as well as transport it etc...

-

-

A bit of off-topic if you don't mind, guys...

Jeff, how do they keep those "basins" clean? And what happens when it rains? Aren't they filled up with water?

-

brooms/blowers for cleaning.. standard drainage techniques for keeping the water out..

most of the times we'll bring the grade up so the bowls are actually above the pre-developed land which makes drainage a lot easier.. (especially in places like florida where you can dig down a couple of feet and hit water.. the structures are basically like swimming pools and there's a possibility of empty pools floating out of the ground if they're built sub water table) -

chris' method is doable too but shotcrete is going to better because it will make it easier to fill voids..

that's how we build these domes: (as well as the one i showed on pg 1 on this thread)

form the edges and one side then screed/hand finish the other side..

-

Okay, thanks!

(I guess they would be full of mud in a bunch of other places around the world already)

Advertisement