Help Me Draw A Dome [TUTORIAL]

-

I was confused at first and now I'm more confused.

-

@chrisglasier said:

And take the mystery out of the topic? Notice I haven't asked why the d0me is in four segments. Another mystery yet to be revealed - eh!

@d0me said:

The Refractory dome will be made in 4 Pieces. Because Refractory material is a quick hardening material, and this is a first time for me, I will cast 1 piece at a time. After all 4 pieces are casted, I will join them together. Because each piece will be casted with the pipe in place, this will automatically create the bunghole in the centre. I will just fill the centre with refractory cement [concrete] to close it of thus creating the "Keystone".

Ah ha!

As the angle at the top is now 90 degrees the acute angle problem has gone away and you don't need the bunghole for that reason. I think you can screed off the sand and lower domes by eye using lines drawn on the form. So you don't need the complication of spinner and so on.

Just make another screeder for the topmost layer with a curve the same as the largest diameter and 2" longer than the quadrant base.

Set up your panel assembly (form), place and compact the sand then carefully lay up the concrete layers evenly not to disturb the substrate using the hawk and steel trowel. Hold the top screeder horizontally to rule off the surplus concrete pressing against the side pieces going from bottom to top if casting vertically *. Of course fill any depressions and rule again. Just as the concrete is beginning to set use a wood float to dress the surface. After that you can use the steel trowel but be careful not to bring too much cement/water slurry up to the surface. (Try it out on the hidden surfaces).

- You might consider making a cradle to sit your form horizontally. Then you could use a slightly wetter mix.

@racer123246 said:

I was confused at first and now I'm more confused.

Just wait for D0me to post the WIP photos. All will be clear.

-

@chrisglasier said:

@chrisglasier said:

And take the mystery out of the topic? Notice I haven't asked why the d0me is in four segments. Another mystery yet to be revealed - eh!

@d0me said:

The Refractory dome will be made in 4 Pieces. Because Refractory material is a quick hardening material, and this is a first time for me, I will cast 1 piece at a time. After all 4 pieces are casted, I will join them together. Because each piece will be casted with the pipe in place, this will automatically create the bunghole in the centre. I will just fill the centre with refractory cement [concrete] to close it of thus creating the "Keystone".

Ah ha!

As the angle at the top is now 90 degrees the acute angle problem has gone away and you don't need the bunghole for that reason. I think you can screed off the sand and lower domes by eye using lines drawn on the form. So you don't need the complication of spinner and so on.

Just make another screeder for the topmost layer with a curve the same as the largest diameter and 2" longer than the quadrant base.

Set up your panel assembly (form), place and compact the sand then carefully lay up the concrete layers evenly not to disturb the substrate using the hawk and steel trowel. Hold the top screeder horizontally to rule off the surplus concrete pressing against the side pieces going from bottom to top if casting vertically *. Of course fill any depressions and rule again. Just as the concrete is beginning to set use a wood float to dress the surface. After that you can use the steel trowel but be careful not to bring too much cement/water slurry up to the surface. (Try it out on the hidden surfaces).

- You might consider making a cradle to sit your form horizontally. Then you could use a slightly wetter mix.

@racer123246 said:

I was confused at first and now I'm more confused.

Just wait for D0me to post the WIP photos. All will be clear.

Hi Chris

I've been reading your post over and over, trying to grip the important advice you have given. I am finding it a bit confusing so I'll take a few steps back.

Firstly, you mention that the angle at the top is now 90 degrees instead of being acute. Would you mind elaborating on you've come to thing conclusion. Sorry, my understanding on architecture jargon is limited to none.

I was always under the impression that a screeder and spinner was the same thing. I was obviously mistaken. Where can I see images of how the 2 work in their own way.

I more or less understand the rest of your advice and it will become even more clearer when I get more clarity on the above points.

As for pics on WIP, most definately. This post will not be complete without them.

Thanks

Regards

D0me -

@d0me said:

Firstly, you mention that the angle at the top is now 90 degrees instead of being acute. Would you mind elaborating on you've come to thing conclusion. Sorry, my understanding on architecture jargon is limited to none.

I was always under the impression that a screeder and spinner was the same thing. I was obviously mistaken. Where can I see images of how the 2 work in their own way.

Originally you had six segments meaning the angle at the top of each segment was 60 degrees - an acute angle. Acute angles in concrete are difficult to make because the material runs out to nothing, and are therefore easy to break.

The screeder in flat work would normally be called a rule or straight-edge, which I thought might be confusing as you are working with double curves. The spinner is just a device that rotates the rule or "curved edge."

But anyway I think what I suggested in my previous post should really give a very good chance to do a good job. Let me know it any part is unclear.

And yes I agree photos are a must!

-

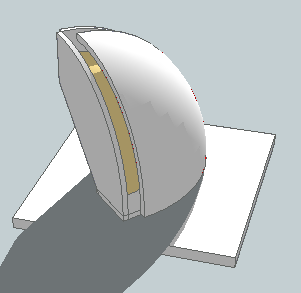

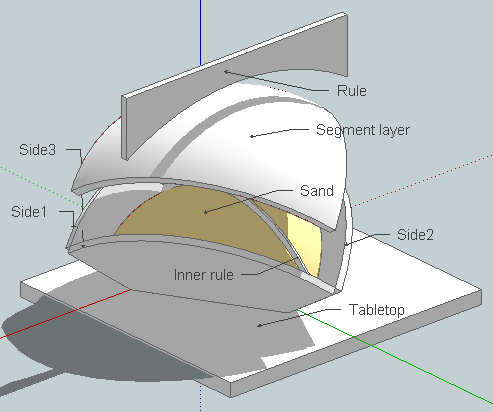

D0me, you may find this Sunday idea the basis for a good solution.

See also sketch .skp

-

Hi Chris

With regards to the spinner, I'm still curious to know what sort of contraption can be made to fit on my wood and the pipe (2" Diameter)?

This contraption should be able to stay in a stationary point on the pipe and spin.

I've thought up a few ideas but had to disgard them because if I have a contraption that will be tightened in place and at the specific height on the pipe, it won't spin if you know what I mean. And if I leave it loose it won't stay at the height on the pipe I wish for it to stay.

Any ideas?

Thanks

Regards

D0me -

Basically you need two pipes one fitting inside the other like a telescopic leg. One has the wood clamped to it and rotates; the other needs to be solidly fixed to keep vertical. The size will depend on what you can find that will work.

-

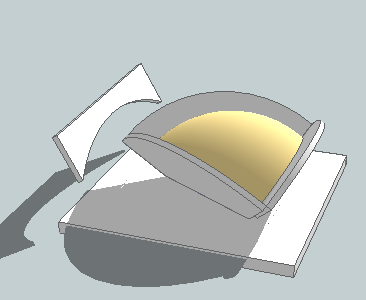

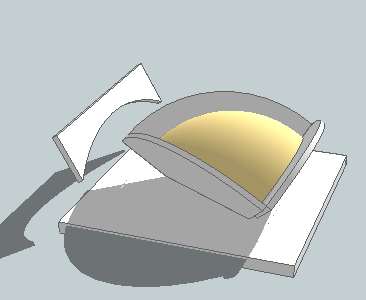

Trying to improve my analytical Sketchupping:

-

One plus one ...

-

Hi Chris

Nice sketching

Can you upload the skp of those images? Would love to get a better view of things.

Guys, I'm also starting to redo the model but I am going to use the advice Gaieus gave and start with the pipe first.

Any tips on how I should go about doing so, like e.g the domes first then pipe or the other way around???Thanks

Regards

D0me -

-

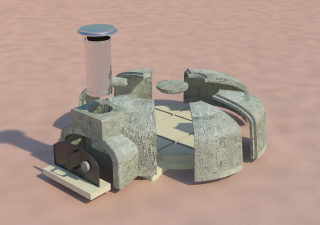

Hey D0me I just came across this:

Have you seen it before?

See the bung, the simple floor, the position of the smoke vent ...

-

Hi Chris

Nice find. Thanks for the link.

Thanks exactly what I am looking to do. One difference is I will pour in my cement to fill the bunghole rather than how they have done it by having the keystone already made.Thanks

-

Hi Gaieus

I'm starting to redo my model and was wondering if you have any tips on how to implement my pipe into the model.

Thanks

-

Did you notice the rebated joints?

You don't want to cast each segment on its back (sketch 1) and then stand it up to demould (sketch 2)?

-

@d0me said:

Hi Gaieus

I'm starting to redo my model and was wondering if you have any tips on how to implement my pipe into the model.

Thanks

Which pipe in this case? The one in the middle you will build the dome around?

-

Hi Gaieus

Yes, the middle pipe around which the dome will be built.

-

I think I should try and clear up any confusion here.

I suggested spinning a screeder around a pipe to realise the job of the

follow metool when you have a point for the apex of the d0me and a circle on the brick base. The curved rule replaces the profile that is extruded. This works fine when there is no obstruction.When you compartmentalise a segment the form sides get in the way, but the sides do provide the opportunity to draw reference curves not very far apart. You can still use a curved rule and get sufficently accurate substrate layers. Most important the last layer will be most accurate using the other curved rule in the opposite direction.

Revised skp showing the inner rule attached.

-

Hi

Chris, should there be any concern or precautions taken should I still choose to leave a bunghole and fill it later. I will require a pipe in my center to help create the bunghole?

Gaieus, I completely forgot about looking through the attachment you posted when i requested how to print my model to scale. Thanks for showing me the steps. That is exactly the way i pictured it my head. Now, just for me to add my pipe and then redo the model, print it to scale and get this "Baby" started.

Look forward to hearing from you guys

Regards

D0me -

@d0me said:

Chris, should there be any concern or precautions taken should I still choose to leave a bunghole and fill it later. I will require a pipe in my center to help create the bunghole?

Just cut a piece out of a plastic pipe if you want a round bunghole or plywood if square; wedge either into top of form. Remember to set on the splay to create a bevel; or form a rebate. But it is really not necessary now you have only four pieces.

Good luck!

Advertisement