Japanese type joinery

-

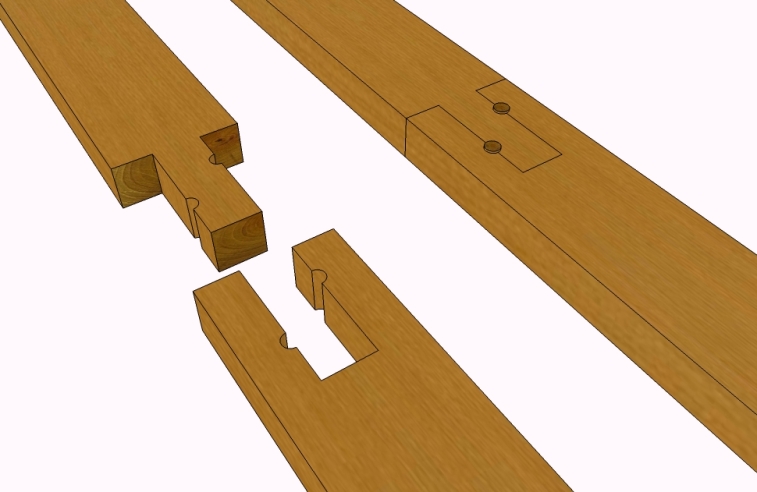

This is a very simple yet ellegent and efficient joint I've used on occaision.

No gluing is needed. Removing the dowels enables you to pull the pieces apart.

-

Quite some time back I stumbled onto a website of a collection of Japanese woodworking joints. One of the things I noticed was that, unlike western style joinery which has a very limited number of joints for making two short peices of wood into one long one, Japanese joinery had a large selection for performing this task. Japanese joinery also depended a lot more on mechanical holding power as opposed to glue surfaces which are prevalent in western joinery. And even so, the few western joints that used more mechanical means in the past have been simplified in the last 100 years or so to become more dependent on glue and less on mechanics. No real reason for posting this other than I found the differences interesting.

-

@sawduster said:

No real reason for posting this other than I found the differences interesting.

I think that's a pretty good reason right there.

-

-

That's very interesting. I think I'll have to have a little google session on Japanese joinery.

-

Gidon, do you hand cut those joints? Have an elaborate machine set up or is it more simple than I am imagining?

Thanks.

-

Very cool. Love wedges.

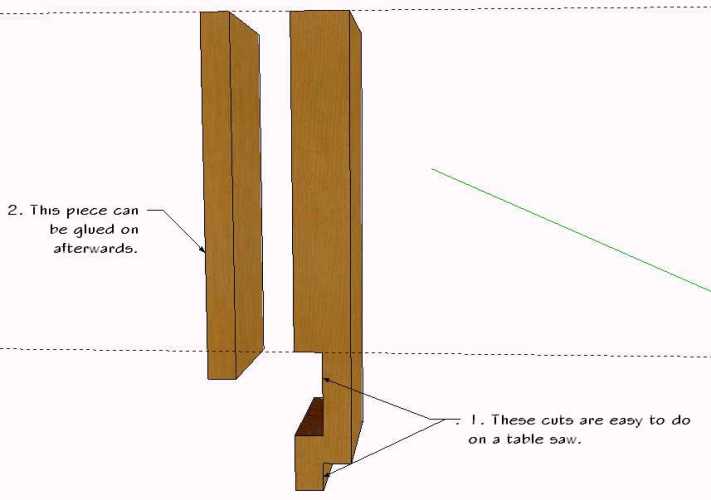

A couple router bits and the right proportions would make pretty quick work of those. When you look at the pieces individually, the joint is fairly straight forward. Cutting by hand, as they were in the past, could be a little problematic depending on the size of the work pieces. Especially the part in the picture below.

I suppose some chisel work could do the job, but . . .

-

Actually, there's an easy cheat. If you don't mind a bit of 'cut and paste' you can make this joint on a table saw by cutting a slice off, making the bottom half of the joint and then gluing the slice back on. If done carefully, the 'cheat' is all but invisible.

-

Oh, I am all about setting it up on a machine. I have never had much success creating any type joint by hand. I can just imagine the amount of scrap I would produce doing test pieces at first

Gidon, who wants to cheat

Man I am itching to cut some wood. I have two friends who want some work done.

-

I can just imagine the amount of scrap I would produce doing test pieces at first

One of the nicest things about doing woodworking with hand tools is the lack of having to make test pieces. While there is a learning curve with hand tools, a bit of practice and you'll get there. I use a combination of power and hand tools and "claim" that I use the most efficient tool for every job. In actuality I mostly find myself deferring to hand tools even in situations where a power tool might be quicker. I do have to justify the large sums of money I have "invested" in vintage hand tools somehow.

-

This is my first post but I couldn't resist when I saw the title of this thread. As my user name suggests I am a woodworker and have been using Japanese joinery in my work for the last 30 years. Now a days I cut all my joinery by hand and can't imanage cutting these joints any other way. Here's a picture of a Kanawa tsugi I cut for what I called my tool frame. You can see more of my work at http://www.mastrowoodworking.com

-

Dang that is a tight joint. And by hand... I am in awe.

And I love the box on you home page.

Welcome and I look forward to seeing more of your work. And what you can dream up in SU.

-

@unknownuser said:

Dang that is a tight joint. And by hand... I am in awe.

And I love the box on you home page.

Welcome and I look forward to seeing more of your work. And what you can dream up in SU.

Hi Boo,

If you click on "The Work" page and click on the fourth square on the bottom row you'll see it's my "Whale Tail Stool".

There's a video of me making that stool under "The Experience" Videos.

There's a video of me making that stool under "The Experience" Videos.

Thanks for the kind words.

-

I like the simplicity of this but, I am a bit curious about the application of this type of joinery? I see that there is references to mechanical applications, are we talking about joints that have to endure stress, strain, shear, etc?

-

Yes all of those. I used this joint to join two timbers to form the bottom on the frame I made to hold my tools behind my bench. I didn't have a piece 12 ft. long so I ripped the 7 ft piece of white fir I had and when I did it came off the saw looking like a couple of bananas but they were a perfect match. I was going to use that joint anyway but decided not to try to straighten them out but use them as is. I think it make the piece.

-

@woodjoint said:

Yes all of those. I used this joint to join two timbers to form the bottom on the frame I made to hold my tools behind my bench. I didn't have a piece 12 ft. long so I ripped the 7 ft piece of white fir I had and when I did it came off the saw looking like a couple of bananas but they were a perfect match. I was going to use that joint anyway but decided not to try to straighten them out but use them as is. I think it make the piece.

That does look really nice. One of the best tool racks i have ever seen in a persons shop to be honest. Most people just slap a few 2x4 boards together and call it a rack.

-

@woodjoint said:

@unknownuser said:

Dang that is a tight joint. And by hand... I am in awe.

And I love the box on you home page.

Welcome and I look forward to seeing more of your work. And what you can dream up in SU.

Hi Boo,

If you click on "The Work" page and click on the fourth square on the bottom row you'll see it's my "Whale Tail Stool".

There's a video of me making that stool under "The Experience" Videos.

There's a video of me making that stool under "The Experience" Videos.

Thanks for the kind words.

Got it. That is beautiful!

-

@woodjoint said:

This is my first post but I couldn't resist when I saw the title of this thread.

Welcome aboard Charlie.

How come this is your first post? With work like that you should have been here ages ago!

Got any skippies to show us?By the way, you owe me a keyboard. I visited your website and just sat there drooling. Apparently, you're not supposed to immerse your keyboard in drool. But hey, I couldnt help it.

Beautiful work, Charlie. -

Thanks for thye kind words, glad you enjoyed my web site. That's true I don't have any skippies yet because I'm really a rank beginner with SU but I'll be trying my luck soon.

-

@woodjoint said:

I'm really a rank beginner with SU but I'll be trying my luck soon.

Any questions you may have don't hesitate to bring them here. You will be hard put to find a friendlier or more generous bunch than the people on this forum. Everything I know about SU I learned from them.

Looking forward to seeing more from you.

Cheers

Advertisement