Ichiban Azumaya!

-

again a wonderful work !! - what will happen to the other half?

again a wonderful work !! - what will happen to the other half? -

Well I get the cedar in end of next week and they're ready to go asap.

I love working this beautiful material and we give it the respect it deserves. This is the full stack of lumber for the main roof structure, 2x8, 2x10 and 2x12, all vertical grain

Some pieces have 30 to 50+ growth rings per inch. It comes from it's home range in Vancouver Island BC.

Some pieces have 30 to 50+ growth rings per inch. It comes from it's home range in Vancouver Island BC.

Beautiful top grade clear cedar timbers in the rough for the 6x8 posts, 4x8 beams and 4x6 knee braces. Bottom left, those are two 20' 6x8 we'll cut in half to get two pairs of matching color / grain posts. You'll never see finer timbers

We use such a High Grade because of it's Beauty, Strength and Stability, Especially Important with these Draped and Curved Roof Designs when cutting big curves in the Rafters out of wide 2x12" boards, you want stock that won't warp, twist and crack after cutting.

You know, for these ‘draped’ roofs, I get the precise shape of each rafter with SUp. I create the draped, compound curved roof plane first, then intersect the rafter tops with it, create dxf of each and then have them cnc cut. You can see that so perfectly in the 4th image I posted, how the underside of the sheathing planes in perfectly with the downhill edge of the rafter tops. Each piece is cut perfectly so the roof almost clicks in to place and the compound curved roof planes fare in so well

Not like the old days when I figured it all out by mind and a couple of books and scribbled it down on paper, then cutting it by hand, then worry all night that it would all fit the next day!

-

Wonderful to see! Thanks for sharing. Best of luck with the work!

-

Completely brilliant and inspiring, your usual standard then. Slightly off topic, how are Cedar stocks and are they realistically sustainable harvest wise? I saw something a while ago about heat and pressure treated Pine that made it as good as hardwoods for example.

-

Joe, my two passions 3d modeling and woodworking

. Great project.

. Great project.John

-

Nice to see SketchUp models being created in real life!

-

Wow! Excellent. Thanks for the shop pictures as well!

-

Well here's another shot of us working in the shop Bryan

-

Awesome shot of the shop!

-

Beautiful work!! Thanks for sharing the pics and the process.

-

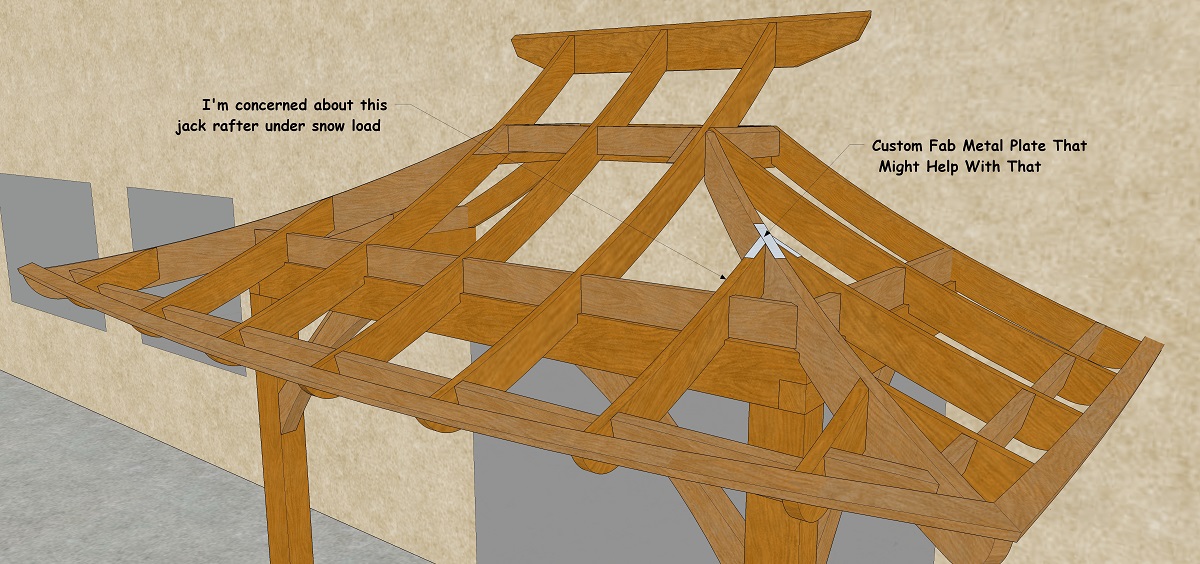

I'd like to run this by you, open to other ideas, but this is going to Pa., snow country! I'm a So Cal boy and know nuthing about snow loads and didn't design this for that. I'm actually getting a liability release from them for any damage / failure due to snow loading

I've come up with this metal plate idea,

-

@joe wood said:

I'd like to run this by you, open to other ideas, but this is going to Pa., snow country! I'm a So Cal boy and know nuthing about snow loads and didn't design this for that. I'm actually getting a liability release from them for any damage / failure due to snow loading

[attachment=0:31eagaw1]<!-- ia0 -->Metal Plate 1.jpg<!-- ia0 -->[/attachment:31eagaw1]

I've come up with this metal plate idea,

Hello Joe,

I am a native Pennsylvanian. That metal plate would fail because its relying on its shear strength rather than its tensile strength. I would recommend using a Simpson H1 hurricane tie and place it flush behind the main beam and attach under the jack.

-

That's a good idea Steven! I've put them on outside of beam but never inside, I can see where it would help a lot! I'm going to look for other ties that could be run up and over the jack rafter.

-

Yeah this is a unique moment in the structure that would require the tie to be located in the back to counter balance. Nonetheless, can't wait to see the final product, it'll look beautiful.

-

So the Ichiban Azumaya! is going up! You need to shout that like a samurai

I give them good installation Info and like I said the CNC cut roof parts almost click together, look at how nice that first skip sheathing fares in

that's a beautiful curve.

that's a beautiful curve.

it's looking real nice! All the skip sheathing is clear vertical grain too.

-

Wow! Looking fine! Looks like they had no trouble putting it up either!

Advertisement