3D Truss Models

-

given the differing sizes used (just referencing what is available in South Africa, not to mention globally), it's possibly best to create options for how many laminates and give the sizing for it...

-

The way I'm setting it up is the first menu takes you to an html web dialog (menu) that allows one to select from standard sizes from drop down menus. Then it automatically drops those values into the regular geometry UI were you can manually edit the depth, width and ply thickness of the glulam so the possibilities are infinite and complete customizable.

I like the ability to offer a prompt that gives standard sizes since I feel that is where some of the value comes in my plugin. It saves the designer having to go to the books to look up an actual available size, its all right there at the click of a mouse.

-

Version 1.1.9 - 12.10.2015

- Added Gable Rafter Roof with Glulam Beam (all advanced options enabled).

-

If anyone can give me links to resources documenting standard sizes for Glulam Beams (metric or imperial) I can work at getting those added into plugin and available for use.

Currently I have the following glulam beam standards available:

[Imperial Units]

- AWC 2012 NDS Supplement Table 1C (Western Species) and 1D (Southern Pine).

[Metric Units]

- AWC 2012 NDS Supplement Table 1C (Western Species) and 1D (Southern Pine).

With metric input the inch units of the NDS glulam selection is converted to mm. This is merely a stop gap until I can get some standardized tables entered for metric sizes.

-

After doing a bit of digging around on the internet I'm not sure standardized metric sizes will be something that is achievable.

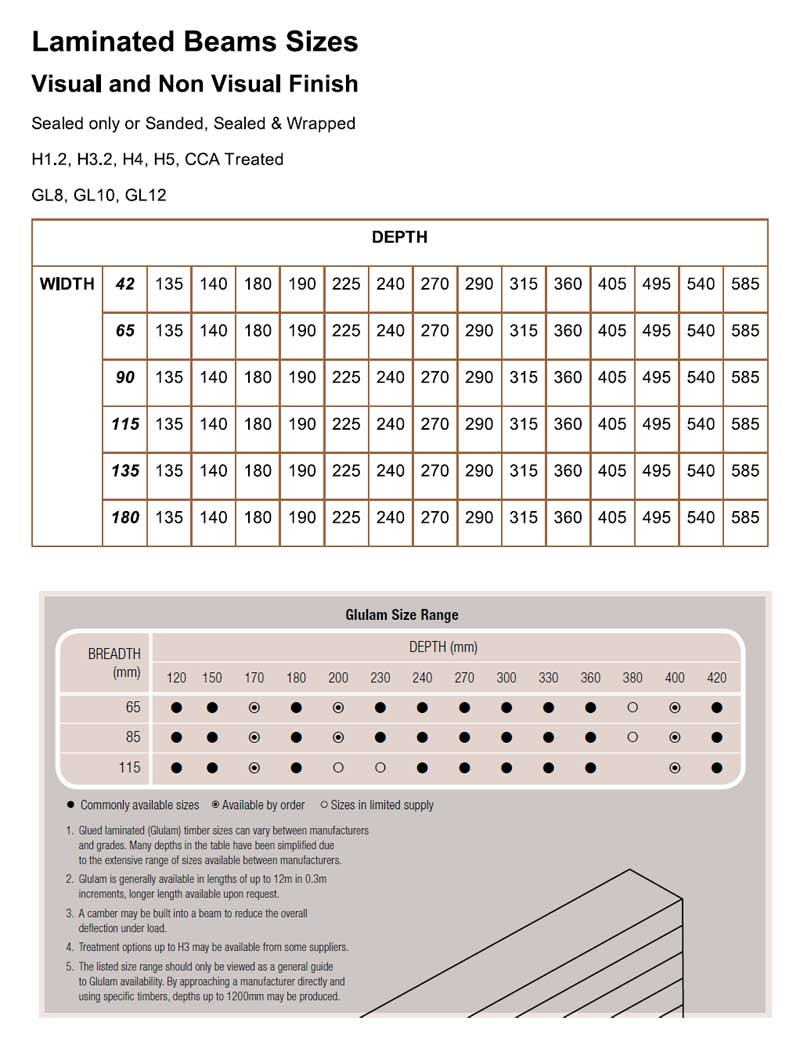

For example two different size tables for glulam beams from two different manufacturers in New Zealand (both conform to the AS/NZS 1328 Standard):

The various widths and depths are all over the board. Is there even a standardized ply thickness? Looking at these tables I cannot tell.

Perhaps other countries in Europe, Asia and Africa have more standardized methods like the United States.

-

In Victoria Australia there are several sources that should be the

same as NZ.One Example is noted below,

Refer to p 10 - p 13 in the pdf document:

http://www.wpv.org.au/docs/STPG.pdfWood Products Victoria (WPV)

The goal of Wood Products Victoria (WPV) is to ensure that sustainable timber and wood products grown, harvested, processed, manufactured or sold within Victoria or by Victorian-based businesses are supported by:› informed research

› credible technical publications

› comprehensive customer information, and

› positive product and market development.

Wood Products Victoria Ltd was established in June 2006.The Board of Directors includes representatives of timber growers, manufacturers, distributors and retailers who wish to ensure the ongoing viability of this sustainable, natural building resource.

For further information about WPV and its activities please email info@wpv.org.au or

call (61 3) 9611 9042.Refer to p 10 - p 13 in the pdf document:

http://www.wpv.org.au/docs/STPG.pdf -

South Africa is a bit different, the two predominant laminated beam types appear to be Pine and Saligna.

Pine laminated beams seem to be very standardized and straight forward.

Widths: 27, 40, 65, 97, 135, 165.

Depths range from 99 to 695

with a 33mm ply thickness.Saligna beams are a bit more interesting.

Widths: 25, 38, 50, 63, 89, 114, 140, 165

Depths: 67, 89, 111, 133, 156, 178, 200, 222, 244, 267, 289, 311, 333, 356, 378, 400, 422, 444, 467, 489, 511, 533, 556, 578, 600...

Ply thickness appears to be 22mm but you will notice it doesn't divide evenly into any of the depths. The actual ply thickness appears to be approximlately 7/8 inches or 22.225mm.Of course I did find some manufacturers whose widths and depths varied from these numbers but most manufacturers complying with SANS1460 generally follow the sizes above.

-

I may have spoken too soon on Australia and New Zealand. There is an interesting table at this link:

Which gives some standard sizes based on Grade. It states that these are the nominal beam widths and depths, I'm not sure if that is the actual size but I will assume so for now.

Some of these depths would suggest that the typical ply thickness is 30mm however there are also quite a few depths where this 30mm does not work. Either there is a different ply thickness for these other depths or they are planing down the larger beams to get to this size.

For example within GL18 the following depths exist: 270, 280, 300, 315, 330. 270, 300, and 330 fit nicely with a 30mm ply thickness, how is the 280 and 315 constructed?

-

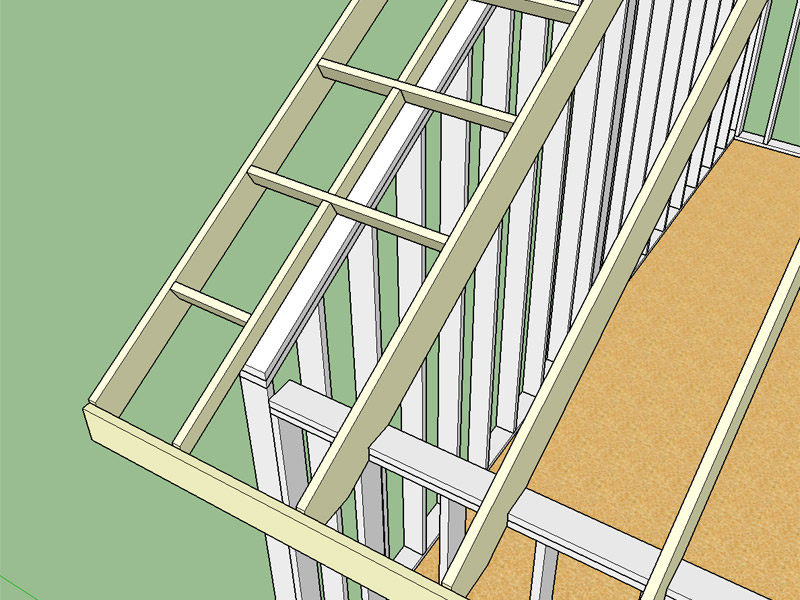

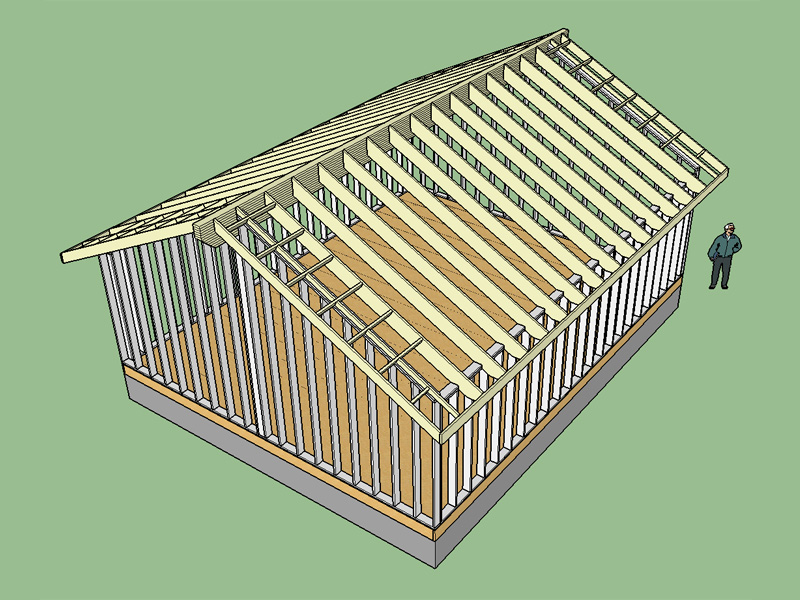

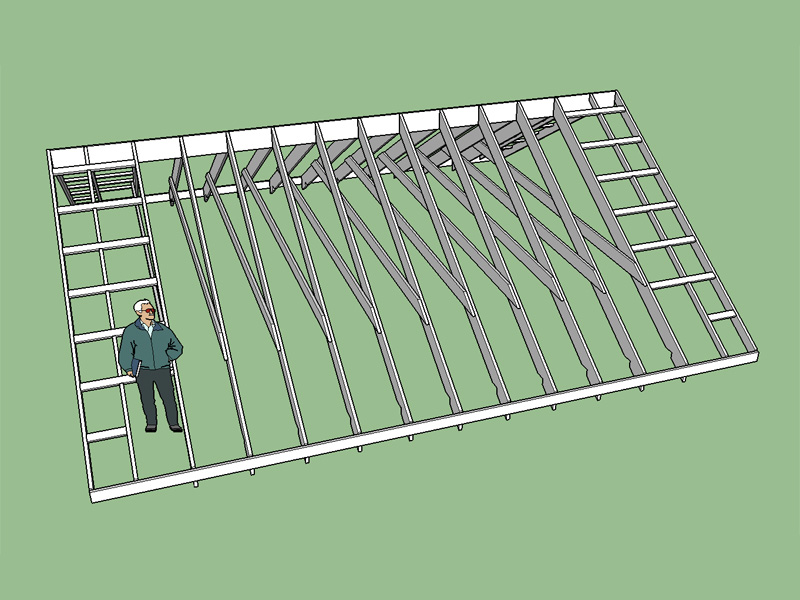

Here is quick model of the wall framing associated with a gable roof with a glulam beam:

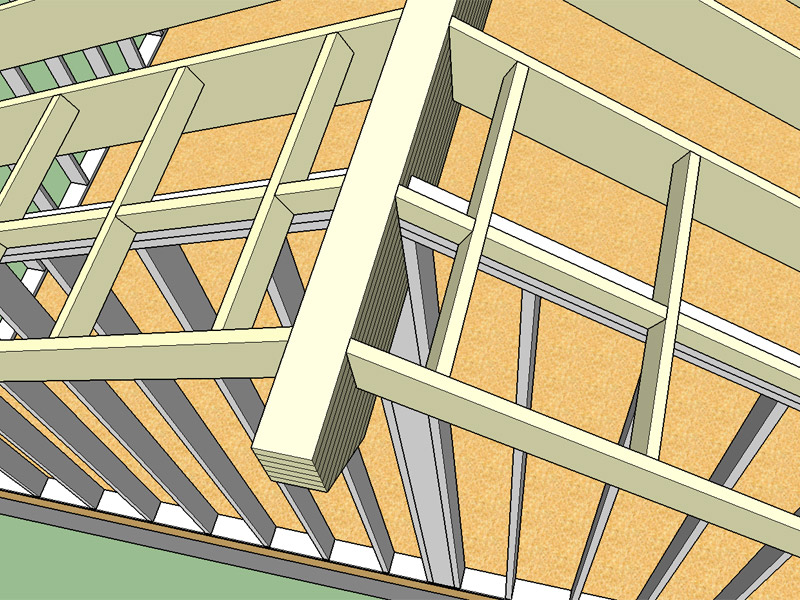

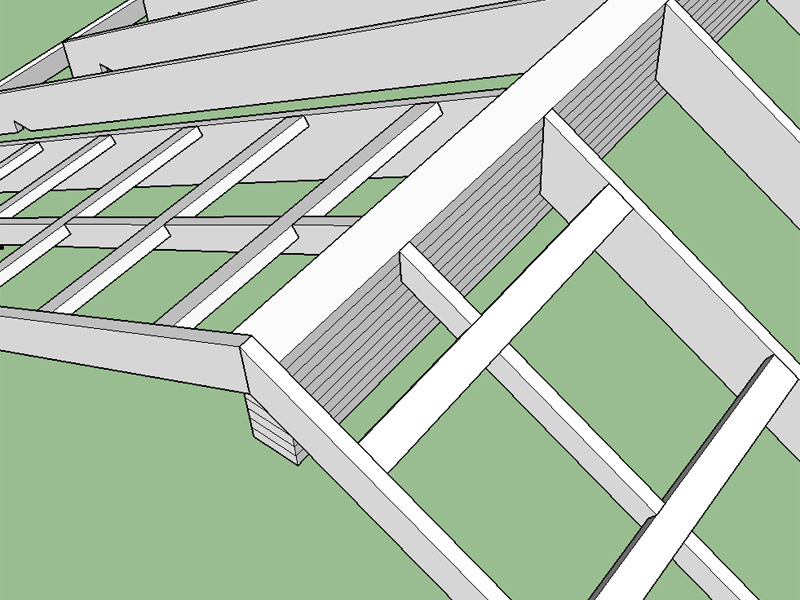

Beam Pocket with 6x6 post:

Gable wall and eave wall intersection:

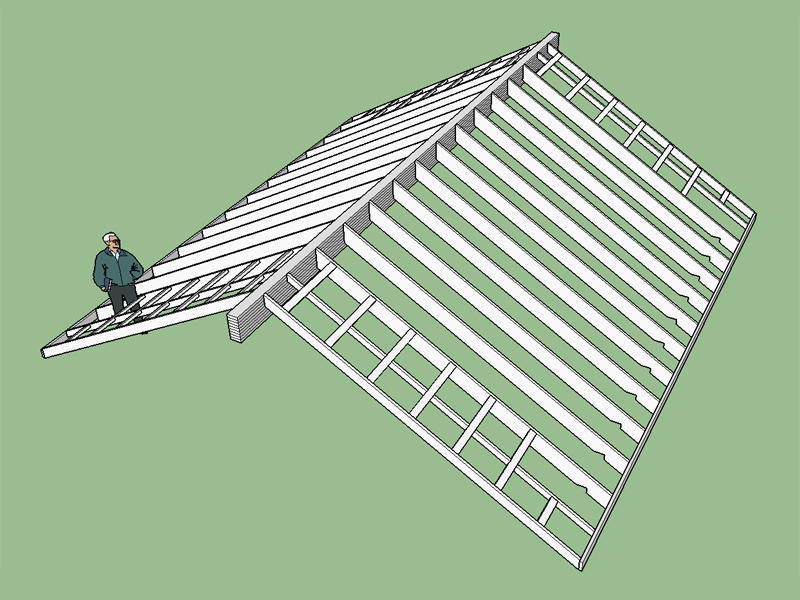

Overview of Model:

-

I've added an extra input for the beam which allows ones to specify the overhang of the beam from the outside of the wall. With zero overhang the beam will be flush with the wall framing and not exposed. If the beam overhang is less than the gable overhang, the fly will be as shown below (up to the roof peak). If the beam overhang is greater than the gable overhang it will project past and the fly will adjust accordingly. The beam overhang is not restricted in any manner.

-

I remember a few years back when I was in college and working a side job as a construction laborer we framed up a roof similar to this. The rafters were large I-Joists (TJI 560 equiv.) and were hangered from the glulam beam. The beam was probably almost 2 feet deep. I just remember I was glad I was cutting the blocking on the miter saw and not the one at the peak of the roof setting the rafters into the hangers.

With that being said I am wondering how often I-Joists are used in this type of application versus common lumber. I can probably add in an option to use them instead of common lumber. One question I have though is what to do at the other end, where they bear at the wall. I would need to study this further.

-

The I-joists are used often here in northern California--I couldn't say HOW often. Not a great deal. I know that on the last project we tried to use them, due to the inability to cut them for various conditions, and the special requirements for bearing, and relative strength, we changed the design to microlams. They are also not as easy in fire rated assemblies.

You are making quite a huge extension! Are various members produced in components for modification afterwards? For example one were to modify all tails. I say this because, obviously you are getting close to realistic representation, but if one is seriously using this to show an actual structures, they will want to add modifications, which occur in every building and can't be put into a plugin.

-

@pbacot said:

You are making quite a huge extension! Are various members produced in components for modification afterwards? For example one were to modify all tails. I say this because, obviously you are getting close to realistic representation, but if one is seriously using this to show an actual structures, they will want to add modifications, which occur in every building and can't be put into a plugin.

Fortunately, someone pointed this out to me fairly early on so I have made it a point to make certain elements components and groups in a sensible fashion.

Common trusses and rafters are always components so that modifying tails etc... can be done quickly and easily. Other items such as fascia, outlookers, sheathing, beams etc... are not components but groups (solids).

Also now that I think about it the outlookers should also be components rather than just groups, added to the "todo" list.

-

Glulam beams in the UK seems to be fairly standardized:

Standard Widths: 90, 115, 140

Depths: 225, 270, 315,360, 405, 450, 495Ply: 45mm

-

All of the pertinent details for I-Joists can be found here:

http://www.woodbywy.com/document/tj-4000/

All have to think about this one. The problem with I-joists is the bevel cuts are more difficult since it requires more operations to model. The outlookers at the gable ends would need to notch around the top flange of the I-joist. A double or single bearing plate is required at the ridge or hangers from the beam, notching at the high end of the roof joist is not allowed. Birdsmouth cut at the low end of the joist is allowed but requires web stiffeners on both sides of the joist.

If I can figure out a good method of making the beveled cuts of complicated profiles that would greatly facilitate things.

Update:

I think if I actually model the I-Joist as three groups, make all the necessary cuts and then union them together I may be able to stick with my simple modeling method points -> face -> pushpull

-

With I-joist roofs don't think I would model in any of the web stiffeners, otherwise the model gets too heavy, same goes for small fasteners and hangers.

I haven't even considered the option yet with the rafters resting on top of the beam (dropped ridge). The I-joist manufacturers do not allow notching at the top end and therefore a beveled bearing plate or strip is required with web stiffeners on both sides of the I-joist. Their detail shows a strap across the tops of the I-joists tying them together across the beam, I'm pretty familiar with this detail from some local jobs I've done recently. However, I'm also wondering about the beveled strip on top of the ridge beam, how is it made, thickness at the butt etc...

With common sawn rafters how would you typically handle a dropped beam? Would you use a beveled strip or would you apply a birdsmouth cut at the ridge? I think I've seen both details but what is the preferred method if there is one.

The problem is I'm not out in the field enough so I never get to see this stuff actually go together very often.

-

When the plugin is loaded in a metric template it will now utilize a web dialog with metric sizes for glulam beams. The menu and glulam beam sizes are currently listed at the following link:

I probably don't list every combination possible or manufactured in each respective country or jurisdiction but hopefully I list the most common sizes. So far I have entered in data for the United Kingdom (Great Britain), South Africa, and Australia (and New Zealand).

I can enter in more countries if provided the data (width, depth, locale name and ply thickness). Now that I have the web dialogs and html files setup it is not a big deal to add more entries.

When the plugin is loaded in inches or feet then the US sizes or AWC NDS tables are loaded. So far I have only found one country that still uses the old units.

-

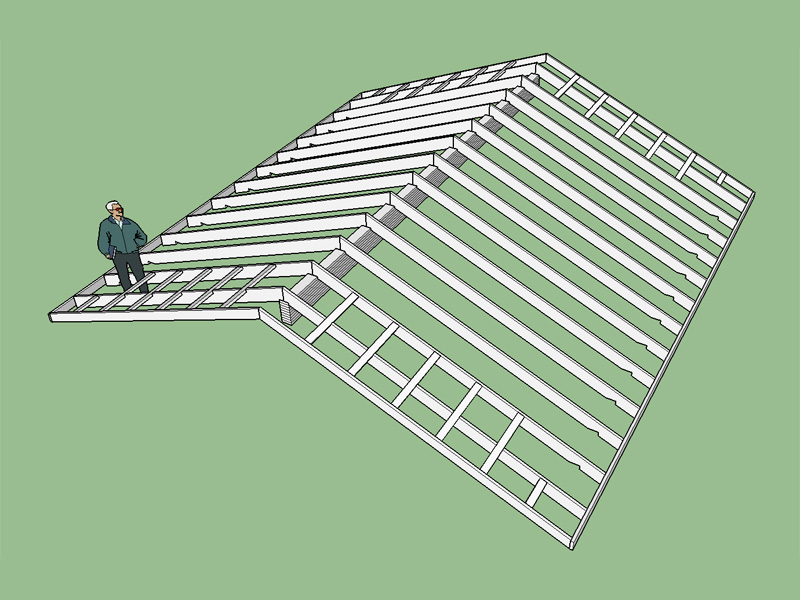

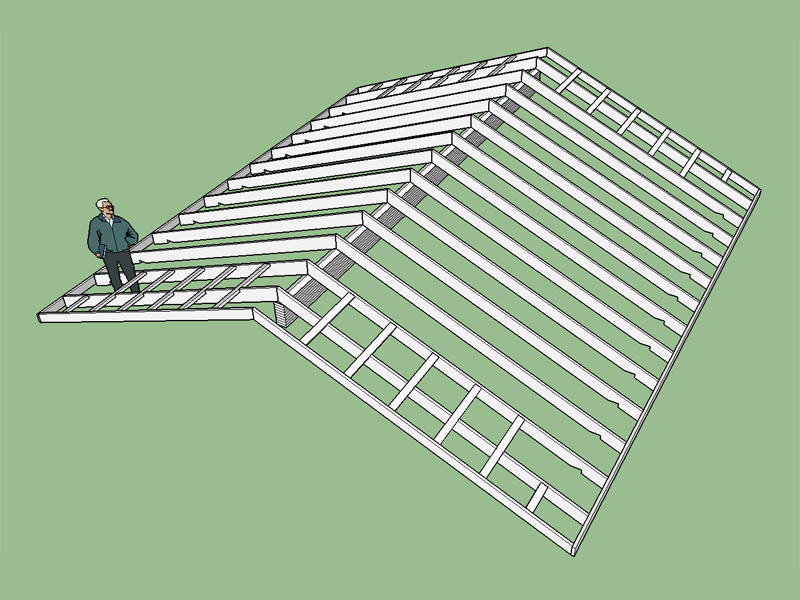

Added dropped beam options for Gable Rafter Roof with Glulam Beam: Notched rafter and Bevelled plate.

-

Version 1.2.0 - 12.13.2015

- Added ceiling joist option for Gable Rafter Roof.

Note: In the image shown I have raised the ceiling joist 24", the default is zero, or resting on the top plate of the wall.

-

With regards to outlookers and I-joist roofs I also noticed in the TJ-4000 (Detail O) they only show the outlookers in a vertical orientation. Are we allowed to do a horizontal orientation (outlookers laid flat)? And if so how do we make that attachment?

Advertisement