There is a plugin wich can do it?

-

@dave r said:

Let me get this straight. You want a plugin that will change the name of a component based upon what components are next to it and how many there are?

Can you write the logic statement for that?

It seems to me that with a little bit of organization of properly made components you would have a pretty simple time of making up a model and getting a list of required parts with quantities.

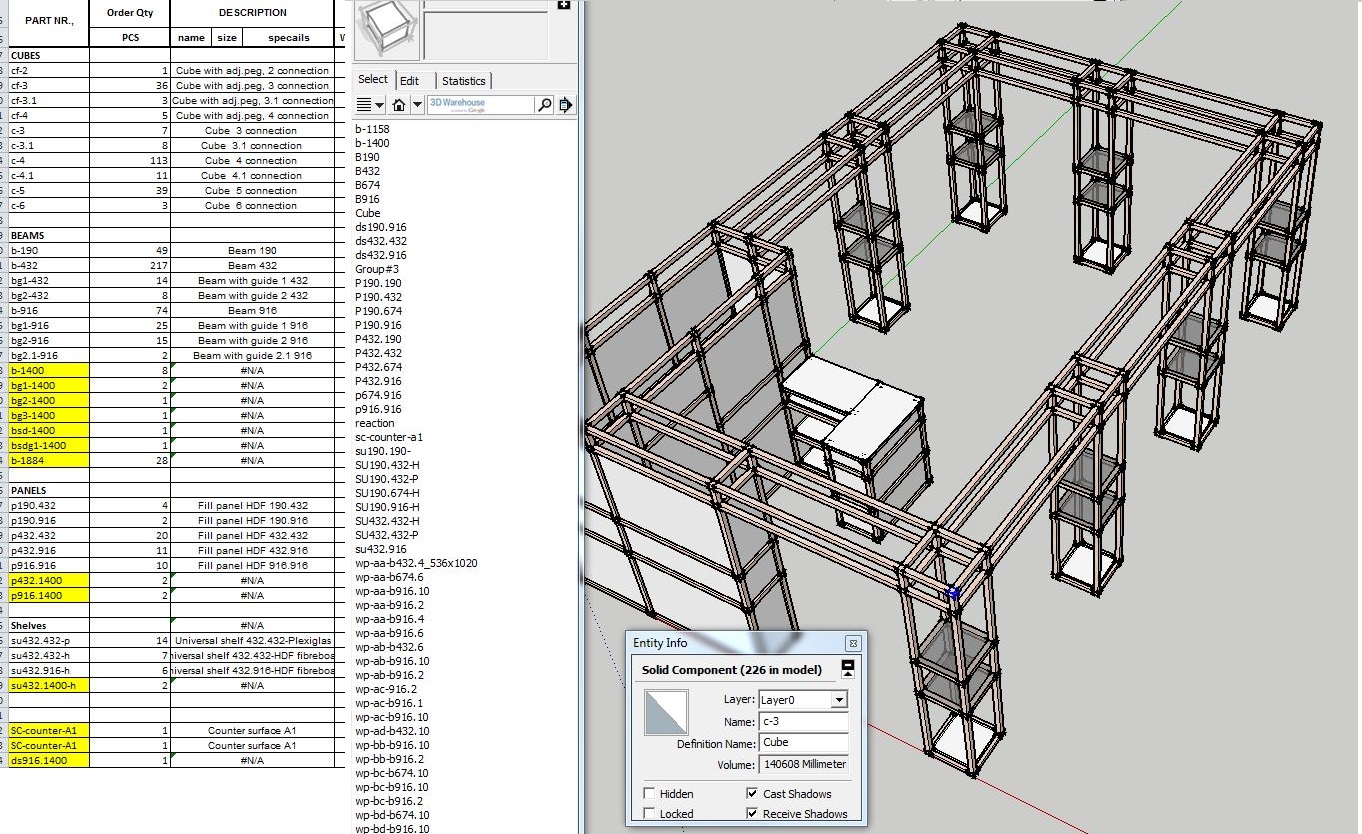

Yes, you understand me right. Maybe plugin can define some places on components and if some component attaches to them then the name changes. See in the picture, about in that way. See on the floor cubes have foot (legs/stand), so they are CF-3 or CF-4, number depending on connections or versions how it connects, as you see C-3 and C-3.1. In the picture there are different beams too, as b-190 and bg1-190, b-190 is simply that long beam, but bg1-190 is beam with groove for panel. There are many more options.

If you know way to do it, please, say.

-

I don't know of a plugin that will do what you want but if you can write the logic statements even in English, someone might be able to make it work.

My approach, which you've already turned down, would be to make the different connectors as components. You could make your beams as components, too. For the beams it sounds like you could manage with two; one without a groove and another with. Just edit the lengths as needed to make the various members. You could then generate a "cutlist" CSV file and in a spreadsheet take the lengths of the beams and use them to create the part numbers and counts for each beam length needed. The cut list would also be able to give you a count of each type of connector.

-

You need to have as many arm components as the system requires...

You need to have just 9 'cube-shaped' connector components.

All the same size and varying just in their in reference, depending on how many connections they will have, and if they are straight-through, right-angles, 2d, 3d etc...

Rotating an instance of a connector will allow it to be used in many arrangements in 3d...Suggested Naming etc:

c1 = single connection - stop-end for 1 arm.

c2 = double connection - 2 arms arranged straight-through

c2x = double connection - 2 arms arranged at right-angles

c3 = triple connection - 3 arms flat in a 2d plane

c3x = triple connection - 3 arms arranged in 3d

c4 = four-way connection - 4 arms flat in 2d

c4x = four-way connection - 4 arms, 1 arranged in 3d

c5 = five-way connection - 5 arms flat and 1 arm is in 3d

c6 = six-way connection - 6 arms in all possible 3d directionsNote: if you have a base level connection, say for 3 arms, and it needs a 'foot', then it's actually a c4/c4x type, NOT a c3/c3x - because it needs to take a 'foot' insert in its base...

But then this is 'your design'...You will need to place these connectors as needed as you assemble the 'arms'...

You do realize the complexity of trying to code something to find the ends of arms and deciding which connector type is to be used, and its transformation into place...You can easily schedule these to CSV using a 'component-reporter' - there are several available ?

To help you visualize what you are doing why not make the nine connectors as different colored cubes, so you can see what's currently where... Perhaps cool to hot shades are they get more and more arms ?

You can have the connector made from two nested groups, one color-coded on layerX and the other default-colored on another layerY - then simply toggle on/off those layers so you can see the color-coded ones OR the 'simple' connector... These nine connectors are actually all physically the same - it's just their names that vary.You can quickly model the various arms, initially using the simplest of the connectors [c1] between them and then later, with all nine connector types loaded into the model, it's easy to use 'replace selected' on some of them to change them to be the appropriate connector; also you can swap them in this way as you adjust arms positions etc and a connector is no longer valid in that configuration.

Remember that you are the designer and these are tools to help you, the tools don't do the designing...

-

@dave r said:

I don't know of a plugin that will do what you want but if you can write the logic statements even in English, someone might be able to make it work.

My approach, which you've already turned down, would be to make the different connectors as components. You could make your beams as components, too. For the beams it sounds like you could manage with two; one without a groove and another with. Just edit the lengths as needed to make the various members. You could then generate a "cutlist" CSV file and in a spreadsheet take the lengths of the beams and use them to create the part numbers and counts for each beam length needed. The cut list would also be able to give you a count of each type of connector.

Sorry for my bad English (My third language)

For me ComponentReporter++ is better then Cut List, because it gives names too, because i name them manually for now. If i make different components then see picture how various i need them. I have grooves for panels and sliding doors or metal plate is glued to beams, and there can be mixed panels, doors and metals on each side, with various combinations and that is with lot of mistakes to do.

Maybe you know plugin that gives out name of component in SU when you drawing or looking around object (name is written on it or some bolt shows that it is there), because with entity info it is too slow - i need to click every component in single if they are not even. I could then just look around and check with eyes.

-

With these arms flat and 3d that is interesting. I think that i need program that could export data with how many arms cube needs, somehow to define these arms.

How much it would cost to make that kind of plugin/program? I'm not programist, but i think that for specialist it is simply. I know that there is some kind of face count + ComponentReporter + defined hands for details + data changer >> I think it is answer!

With those color changed beams i tried for about week, but then i needed 33 colors, and there were real mess and my goal is to make counting automatic with as small number of components i can.

-

I don't understand your logic, of how you model the assemblies, or how you then want to extract information from the model...

There are 9 potential connectors, assuming 90 degree arm arrangements.

There are as many arms [aka 'beams'] as you decide there will be.They all connect to a connector at each end, but their lengths and cross-sectional details can vary - e.g. simple square cross-section arms, cross-section 'slotted' to take a panel - this can be on 1/2/3/4 sides - and in combination with the other variants/lengths increases the possibilities exponentially... Your catalog-illustration has even more possibilities - like double-slots for holding sliding-doors, three sided arms for recessed lights, all in permutations with other detailing...

Let's make a 'thought-experiment'...

You have 9 connector components and a set of simple square cross-section arm components, in three standard lengths = 1/2/3 'units'

With these you can make assemblies in many ways.

Now you can make three more arms [of the same lengths], this time with a slot in each face.

These can be swapped with the existing ones using 'replace selected' tool for components...

Next you make a set of double-slotted arm variants to use with sliding-doors etc, this way you build up your 'kit-of-parts'...

You cannot expect a 'program' to make decisions for you, you are the designer and decide what goes were... If you name your connectors and arms [beams] sensibly then scheduling out quantities is the easy bit... To help yourself see what you are doing I already suggested the idea of color coding the connectors using layers within the components to let you toggle between the colored and plain versions: you can do that with the arms/beams too - there are probably fewer permutations for these because different lengths of the same cross-section can be the same color, you ought to be able to 'see' that an arm doesn't stretch between two connector 'nodes' ?? -

@tig said:

I don't understand your logic, of how you model the assemblies, or how you then want to extract information from the model...

suggested the idea of color coding the connectors using layers within the components to let you toggle between the colored and plain versions: you can do that with the arms/beams too - there are probably fewer permutations for these because different lengths of the same cross-section can be the same color, you ought to be able to 'see' that an arm doesn't stretch between two connector 'nodes' ??My logic is simple - i want just draw with one cube and different lenghts of beams, panels, wall panels etc. and all details counts automatically. If i connect specific detail in specific place then it renames to needed. There is nothing unlogical. I don't know if such program exsist, but also think that with the right approach it could help to many estimators. When i design i don't think about details, but later i need to count and mistakes happen or i change later something and didn't rename one detail and manufacturer has wrong count of details. I'm just looking solution for mankind mistakes with scientific calculation.

This plugin could be revolution too, because it would show if something is embed in detail if it is in right place where it needs it, for example, drillhole, bolts, grooves or something else and you get it written by codes you know. And if you know that you defined all correctly, then you can trust program and just draw with universal components and get report automaticaly.

-

But putting your programmer's hat on for moment, and assuming we only have one kind/length arm/beam [to at least remove the complexities of multiple lengths and cross-section types etc!] and you use a single 'blank' connector-cube 'node'...

How are the arm/beams going to automatically 'snap' correctly onto these 'nodes'?

Or conversely the node auto-snap onto an end of an arm/beam?

How is your new wonder program going to establish where everything is relative to everything else, how it is oriented and so on - let alone what it's 'connected' to ?

Assuming all of the arm/beams are snapped onto nodes then how does each node 'know' what is connected onto it?

Assuming it can do this and it does update itself to have the correct 'code' for that configuration of arm/beams etc... then if you were to add or remove an arm/beam how does a node 'know' this and then update its own reference etc...I'm sure all this is possible, BUT it would require a very very complex set of components with inter-related attributes, change-observers etc to make a solution to even the simplest of 'kits'...

I think you underestimate the difficulty of making a tool to do this, by a factor of several orders of magnitude. -

I don't understand where can be an isolated cube except in the box packaging?

Seems on your building structures examples all pieces are connected ?

Maybe p190.190 ? But it's not structure! -

@tig said:

But putting your programmer's hat on for moment, and assuming we only have one kind/length arm/beam [to at least remove the complexities of multiple lengths and cross-section types etc!] and you use a single 'blank' connector-cube 'node'...

I think you underestimate the difficulty of making a tool to do this, by a factor of several orders of magnitude.

If i could define some points on beam that could give answer what component connects it or in how big precisely area on beam there is connection and with IF functions it could be programed.

If all sides of cube where defined with codes and no matter how i change its dimensions then it could be done.

Maybe some electrical program could answer, because it feels if there is electrical current.

See and read on pictures..

-

@unknownuser said:

I don't understand where can be an isolated cube except in the box packaging?

Seems on your building structures examples all pieces are connected ?

Maybe p190.190 ? But it's not structure!I don't understand the first.

Yes, they are connected. p190.190 is panel 190x190x3. It is too conected between beams with groove. I only need defined faces and to know what connects them..TIG, I see thet you made ComponentReporter in 2007, but there isn't something new - more complex? It gives out good information and is better then CutList for me, thanks, but if it only could gives out connected details too and there would be defined sides...

See picture! Sides meaning faces. If there is 8 faces then 8, i have cube,i need only six. If it gives out this information, then with excel i could make some algorithm.

If I tried to write plugin, then i can write it in notepad? If i read program i can understand something, but don't understand how it is linked to work, i don't know key words too.

Advertisement