From SketchUp to Reality

-

Hello Simon

It is always a pleasure to have your input.

You make some very good points, and one, about why walls aren't done completely with ICF is one of those choices that you make on a building.

The reason I chose this route is that it there are two complications with any of the walls that rise above the roof on this building. The first is there are lots of windows in them, and because of the groupings of windows particularly the front Living room (steeper pitch) section it ends up mostly windows. In a situation like this it is really important to get the concrete to completely flow around and encase the window. In some of the small spaces that I had to deal with this would hve been next to impossible.

The second is concrete lintels. These are the "beams" that run over the windows. Again given their size, and the amount of reinforcing steel required, as they are holding the roof loads, it makes them very difficult to do.

Having said that in retrospect, I would most probably have brought the wall at the front of the Kitchen up, if I were to do it again, as there would have been enough room around the windows to have done this, and it would have saved some complex framing.

The pipes within the floor are run at 6" intervals in most of the house, and 12 in areas that we didn't want a lot of heat.

There is well over 3000 lineal ft (914 m) of pipes in the floor.(at about 70 cents per foot)

This is recommended when using the geoexchange system, because the warmer the water returns to the machine, the more efficient the machine is. Given the efficiency of the machine, and the cost of electricity, I expect to recover the difference in cost over the system I would have put in in 4 years.

The fireplace actually has a layer of 2" styrofoam which connects to the exterior Quadlock, and encases the fireplace between the rough in concrete blocks and the finished stone.

WE had to argue quite hard to be allowed to do this as code does not allow combustible material within 1" (2.5cm) of the fireplace. At the closest point the styrofoam is 2' (.61m) away from the firebox, so I don't think this would burn. I won't deny though that having the full masonry in the house would have been better. Although we look at several different interior locations, in the end this worked better for us.

We tried several different placements of the fireplace, but in the end.

I am currently designing a house for a client that will be Quadlock (#21 Quadlock house I believe)

and I will be adjusting things from what I learned from this one.We are awaiting the drywallers, and I can say this thread will get quite active at that point, as I will move my woodshop into the house and start building the doors, cabinets, and millwork.

That in my mind is truly where the fun begins.Cheers Simon and Pilou and thanks for the kind thoughts.

PS Simon... Been to any good concerts lately?

-

Dear Dale,

So nice to meet you again

Thank you for your precise explanations. They help to participate to your project (you are a bit too far to lend you my arms )

)

The reasons you had made the upper floors in wood are very instructive ++ Can we say that the concept of passive house(Passivhaus in German) is maintained by this way?This is something I like deeply in my inside to understand and ear explanations about architectural (and mechanical) choices. May be in another life I would had been an architect!! This probably come from my family consisting of a line of building engineers.

The most famous of them was my great-grandfather from my father side, Armand Considère which was one of the inventors and great promoter of reinforced concrete construction...here are some links dedicated to him:

Armand Considère

http://en.structurae.de/photos/index.cfm?JD=62

http://www.planete-tp.com/article.php3?id_article=1282

[url]http://fr.wikipedia.org/wiki/Armand_Considère[/url]And here is a beautiful family picture which shows him accompanied with his daughters (one is my grand mother

)

)

[url=http://i274.photobucket.com/albums/jj245/Spendauballet/generalPicts/MretMellesConsidere_enbateau.jpg:19p3sf3o]

[/url:19p3sf3o]@unknownuser said:

PS Simon... Been to any good concerts lately?

Here is my last one, dedicated to you

[url=http://i274.photobucket.com/albums/jj245/Spendauballet/generalPicts/2011-11-21_201358.jpg:19p3sf3o]

[/url:19p3sf3o]

[url:19p3sf3o]http://forums.sketchucation.com/viewtopic.php?f=179&t=21899&p=367194#p367194[/url:19p3sf3o]++ simon

-

Well, after buttoning of the poly vapour barrier, and sealing all the seams with Tuck Tape, (actually the nice tapework is Judy's, I did the 'Frankentape').

Windows are time consuming.

But the nice thing about building your own place, is you can at least have some nice ambience

Well the truth is the plants have been living on the downstairs windowsill, and Jude moved them up to clear the way for the drywallers.

This picture does show the fireplace stonework after Judy cleaned it with muratic acid, and put a finish on, which really brings out the character of the stone. -

But at last.... The drywallers, (Todd and Tim) are on the roll

This is a really small town in the mountains, 2 hours from the nearest major centre, so having a real drywall tradesman like Todd is just pure luck.

They are a really heads down, nose to the grindstone team.

-

Meanwhile, upstairs on the main floor Jude and I are laying the stone floor.

First we prepped the bathroom by laying down a skim coat of concrete to the top of the hydronic pipes, unfortunately I forgot to take a picture of this.

Then we lay down a rubber shower pan which clamps directly into the drain. WE put a pan throughout the whole room, as we don't want a curb at the shower entrance, just a level walk-in.

Then place aluminum expanded metal lath on the pan to help reinforce the mortar.

The start the stonework.

The stone is a silver mica, about 1/2" (1.3 cm) thick. I have already burnt out one diamond blade that I use to cut it because it is so extremely hard. The full floor depth is 2"(5.1 cm)

Then when it has set overnight Judy cleans it with muratic acid to get the excess mortar off, and washes it down.

-

The stonework will be in the small guest bath (with the shower), the master ensuite, and the kitchen.

Each floor has a thermocoupler sensor that connects to a programable thermostat which will allow us to set the temperature of the floor.

In the areas other than the shower, there is no rubber pan, so the lath is place over the hydronic pipe, and the stones laid directly.

Me laying stone.

And if I go out to make another mix of mortar, Judy just keeps going.

Each of the bathrooms took a full day, with cleaning the next morning, and the kitchen will take about 3 days.

So it's back to work on the kitchen.

Cheers

(Oh and yes that is a laundry chute in the top right of the last photo) -

Dear Dale and Judy,

Things are really going on!!

Each step is carried out with great attention to detail, in a spirit of perfection. It's so pleasant to watch

I continue to be amazed by all the techniques that you implement..

-I didnd't know we could revive the stones with Muriatic acid (Historically called muriatic acid, and spirits of salt, hydrochloric acid was produced from vitriol (sulfuric acid) and common salt. The earliest suggested discovery of hydrochloric acid is attributed to the alchemist Jabir ibn Hayyan (c. 800 AD).- "we lay down a rubber shower pan which clamps directly into the drain."

- "Then place aluminum expanded metal lath on the pan to help reinforce the mortar."

- "Each floor has a thermocoupler sensor that connects to a programable thermostat which will allow us to set the temperature of the floor."

nice..

nice.. - "(Oh and yes that is a laundry chute in the top right of the last photo)" that is top

Oh! and now that's it: The cold is arrived

Have you win the race, or does some works are lost under snow for this season?

Cheers,

Simon. - "we lay down a rubber shower pan which clamps directly into the drain."

-

Hey Simon

Fickle weather here.

Last week we dipped to minus -19(C), yesterday was +6 (C) and rained a lot of the snow away, and the went to below 0, and snowed like crazy.

But winter can be sooo beautiful.

I will still do some exterior work, even in the cold, but we plan on a mixed set of siding which will include stone and stucco, so that will not be until spring.

By the way I really appreciate all the links you post that take me on interesting paths, and a real vote of thanks to your Great Grandfather. Structural concrete has allowed some of the great beauties of architecture to be built, and I'm sure in his time it was scoffed at by the Status Quo. -

@unknownuser said:

By the way I really appreciate all the links you post that take me on interesting paths, and a real vote of thanks to your Great Grandfather

Dear Dale, I'm so pleased you appreciate (and sorry for bumping this way your thread). Searching to find more in order to give some powder to this reply, I have found very interesting things (and especially a book written by my great grandfather which I didn't know). I have found also that the real big men around reinforced concrete at this time were Eugène Freyssinet and Albert Caquot. So would you please let me bump a little more and for the last time your thread with these last links, mostly in french. ( no comment: just in the case people be interested)

PELNARD-CONSIDERE-CAQUOT 1994 035

http://www.archivesnationales.culture.gouv.fr/camt/fr/egf/donnees_efg/1994_035+2007_048/1994_035_INV.pdf

Experimental Researches on Reinforced Concrete (1906) by Armand Considère

http://www.archive.org/details/experimentalres01consgoog

Albert Caquot portrait: [url=http://sabix.org/bulletin/:27vfjpjp]bulletin[/url:27vfjpjp] de l'école polytechnique ([url=http://sabix.org/:27vfjpjp]Sabix[/url:27vfjpjp])

[url:27vfjpjp]http://sabix.org/bulletin/b28/28.html[/url:27vfjpjp]

[url:27vfjpjp]http://sabix.revues.org/370?lang=en[/url:27vfjpjp]

Les chocolats Menier, le pont Hardi et Armand Considère

[url:27vfjpjp]http://pone.lateb.pagesperso-orange.fr/pont hardi.htm[/url:27vfjpjp]

http://pone.lateb.pagesperso-orange.fr/armand%20considere.htmCintre du pont la Caille sur le ravin des Usses, en Haute-Savoie (1928).

Le pont de la Caille sur le ravin des Usses (1928), record mondial à l’époque

end of the bump

++simon -

Hey Dale, isn't it fun doing the inside 'details'? I've been doing trim on my self-build timber frame for what seems like forever and it still has a want to go. I think the trick is to make sure you make some progress every day and just keep at it.

I have a build blog athttp://www.rowledge.org/tim/building/building/blog.html for anyone interested - including full SU and LO files.

-

Simon

What a beautiful structure! As usual you have snet me on a really interesting exploration.Tim

Thanks for the link to your blog.

What a beautiful house, and I really admire your attention to detail, but given your background in computers and code, I'm sure detail is second nature.

We seem to have a lot of similar taste ( ICF, Douglas Fir )and influences (Tedd Benson, Sarah Susanka) plus a love of woodworking (and tools) and time in the hallways of Colleges of Art. Not to mention the "From SketchUp to Reality" path of house building.

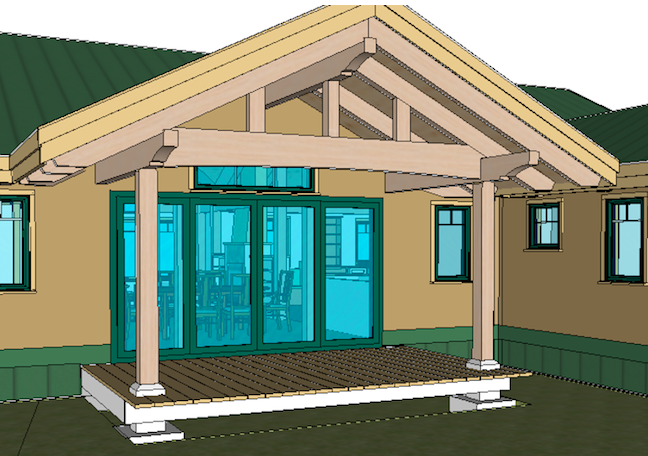

I hope you don't mind... I poached one of your Illustrations in SketchUp to encourage people to visit your website and blog. Well worth the visit and really inspiring.

Here is the link againhttp://www.rowledge.org/tim/building/building/blog.htmlKeep on trimming!

Oh and I still consult for a Nanaimo Company, and do make it down to the Island from time to time.

Maybe we can meet sometime, and I can buy you a beer.

Cheers -

Fantastic! We are considering building our own slipform-style stone small home in the woods ourselves. Nice to see we aren't the only crazy ones out there with the idea. Thanks for the progress shots.

-

Dale, have you considered a submission to here?

http://sketchupdate.blogspot.com/2011/11/how-do-you-make-ideas-real-with.htmlI think it would be very a interesting read for many.

-

@gaieus said:

Dale, have you considered a submission to here?

http://sketchupdate.blogspot.com/2011/11/how-do-you-make-ideas-real-with.htmlI think it would be very a interesting read for many.

Thanks for this Gaieus, I wasn't aware of this. There are some quite interesting projects shown.

I will have to give it a go. -

Meanwhile, things are plodding along.

We finished the stone floors, well all except my thermostat floor probes haven't arrived yet, so I had to leave out an area where we can insert those.

The Stone is a silver mica, and came out a beautiful grey blue when we put the finish on it.

The drywallers are hard at it, just one more coat of mud on the basement to go, and they have all the upper floor ceilings hung. Here's a picture of Todd, I'm sure cursing my skylite chute

-

So with the drywallers inside, I went outside and started soffits.

Weather is hovering right around the freezing mark, so it's not unpleasant at all.

The soffits angle back down to the wall from the fascia, and have miters on the corners. So the old compound miter head scratching.

The soffits are pine 1x6 tongue and groove, and of course require venting, so I let the vents in to the pine.

And with the pine started.

So it's back up the scaffold I go.

Cheers! -

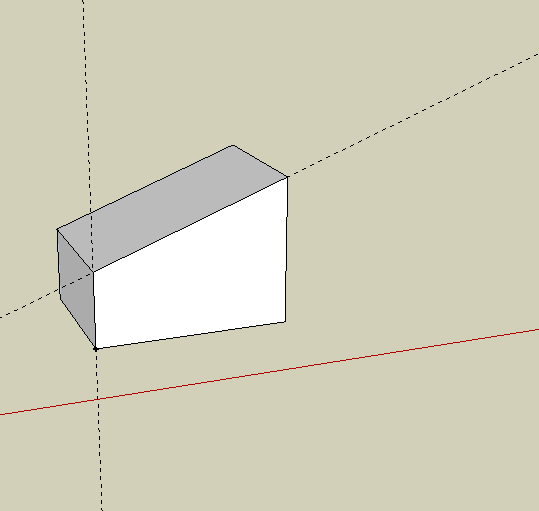

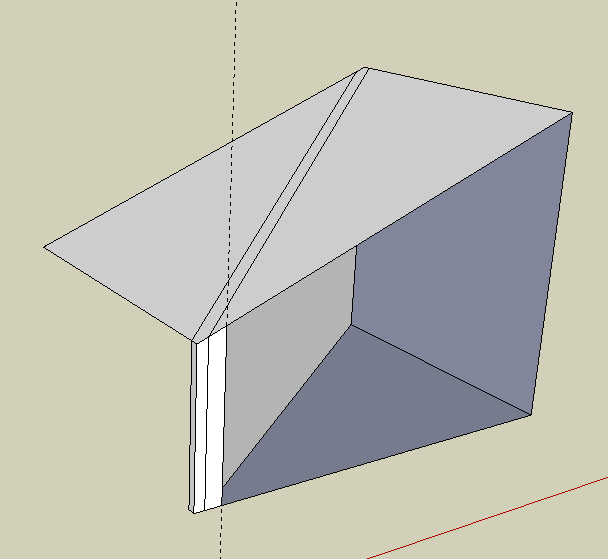

Oh and since this is a SketchUp related thread.

Since I haven't been on the tools for 7 years or so, I got lazy and figured out the compound miters in Skp.

The soffits have a 5' (1.52m) overhang on the front and 3'(.91m) on the sides

-

@dale said:

What a beautiful house, and I really admire your attention to detail, but given your background in computers and code, I'm sure detail is second nature.

That and being borderline sociopath/obsessive-compulsive…

For anyone else contemplating their own build I'd reiterate that obsession with detail thing; so many contractors are happy to let precision slip because it's just a job to them, day in, day out. If you show them the potential for making something nicer than they usually get to do, take part in the process and the work, turn up with enthusiasm every day, then it is amazing how much harder most of them will try. Details matter during the build, after the build as you live there and later when you want to change things.

It's also good to live on the Fine Homebuilding website for a year or two to learn (at least) the words and phrases that communicate some knowledge of what you're up to. Better yet, you're likely to know something new in the field that might interest your subcontractors.

@dale said:

Oh and I still consult for a Nanaimo Company, and do make it down to the Island from time to time.

Maybe we can meet sometime, and I can buy you a beer.

CheersNice idea Dale. Sounds like a plan…

Oh, and

@dale said:

Since I haven't been on the tools for 7 years or so, I got lazy and figured out the compound miters in Skp.

I can't count the number of special printouts I did from the SU model to illustrate a detail of the roof decking angles, or rafter tenons, or electrical layout or, or, or. Invaluable.

Advertisement