Lifting capacity of a bolt ?

-

Sorry if I missed this in the discussion and/or it is missing from the drawing detail, but how do you plan on preventing the bolt from turning as you tighten the nut?

It's possible this may not be a problem using the impact driver, but if it is you may need to have another wrench to keep the bolt from turning. There appears to be 2" clearance, which should be just enough room to get a wrench on it.

(edit - probably stating the obvious.)

-

@jim said:

Sorry if I missed this in the discussion and/or it is missing from the drawing detail, but how do you plan on preventing the bolt from turning as you tighten the nut?

It's possible this may not be a problem using the impact driver, but if it is you may need to have another wrench to keep the bolt from turning. There appears to be 2" clearance, which should be just enough room to get a wrench on it.

(edit - probably stating the obvious.)

yeah, a combination wrench on the other side.. i got the flange bolts with serrated edges which will help a little bit by biting into the tube..

the tube is actually 2x2 (1/4" wall) so that's why i got the 5" bolt... at the end of it all, the bolt will stick up an inch so a socket will still have clearance. -

Go Jeff!

-

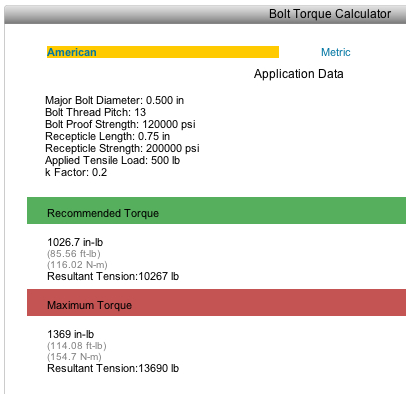

i found this online calculator that will give you the necessary torque for an applied weight

my results are saying that i should be able to do this with my impact wrench (capable of 1400 in.lbs torque).

that said, it did give me a warning when i entered the receptacle length of 1/4" which is how the lift would start off with the 5" bolts (the nut wouldn't fully encapsulate the bolt until i lifted 1/2") and they recommend 3x the bolt diameter as the receptacle length... so, i changed my bolt order to get some longer bolts which will allow all the threads of the nut to contact the bolt prior to taking on any weight.

it's gonna delay the move a few days but hey.. better safe than sorry right?

-

That's an interesting 'torque calculator' you found.

Are they Grade 2 4140 bolts you're installing? Either way grease them up to lower the torque required though you're probably well aware of that.

I used to install 1.5" stainless steel cone bolts in MD-80's with a 4' torque wrench. Then go up on test flight. All that was in my head was 'i hope those f$%king bolts were ok'.

-

@unknownuser said:

That's an interesting 'torque calculator' you found.

Are they Grade 2 4140 bolts you're installing? Either way grease them up to lower the torque required though you're probably well aware of that.

they're actually grade 8 bolts which i thought would be super expensive but they were only 6 bucks each (ok, relatively super expensive but i only need four of them soo..

)

)the bolts are way too strong for what i need them for but i don't mind..

thing is, i'll be doing this in an open air ad agency with maybe 100 or so people inside.. many of those people are rather beautiful women and i think i'm a bit more worried about them seeing something go wrong as opposed to simply being worried about something going wrong

..so i'm just making sure i have all bases covered.

..so i'm just making sure i have all bases covered.@unknownuser said:

I used to install 1.5" stainless steel cone bolts in MD-80's with a 4' torque wrench. Then go up on test flight. All that was in my head was 'i hope those f$%king bolts were ok'.

what?! are you serious? that's crazy sounding.. (though i wonder how many md80s i've been on with less than optimal bolts/rivets etc.. or do those types of things get checked fairly thoroughly/regularly ?)

-

.

ok.. so 1655 lbs worth of K6 - British Red Telephone Box has been successfully relocated by a single person

and it was actually a lot easier than i was thinking it would be.. everything went very smooth.. maybe a bit over engineered as far as the quality of bolts and steel thickness i used but -oh well... ended up just using a ratchet to tighten the bolts -- i don't think 1000 lbs of torque is as much force as it sounds like.. or maybe i'm just superman

-

Torque= Force x Lenght

So divide the torque by length of wrench to figure out how much force you applied to reach that torque. In/lbs are different from ft/lbs but I'm sure you're aware of that.

If I'd known you were lifting that I'd have suggested the Irish method known as 'horsin' into place'

-

Ha. Yeah, I would of approached it differently if my crew was nearby but flying them into NYC for this would of been a bit overboard. My method is called "move that s@!&, A$$h@?3" which Is probably similar to horsin.

And I didn't feel too comfortable asking people with fancy fingernails playing on fancy computers to help out with the grunt technique

-

Shall I PM my paypal details? I was a consultant on this after all

I didn't want to mention the caliber of your clients, but I imagine they only break sweats when they run outta bryll cream and moisturizer.

-

@unknownuser said:

Shall I PM my paypal details? I was a consultant on this after all

the check is in the mail.. should arrive soon.

@unknownuser said:

I didn't want to mention the caliber of your clients, but I imagine they only break sweats when they run outta bryll cream and moisturizer.

super cool people though.. i do a lot of random odd jobs for them when i'm in town.

Advertisement