Invitation to the SketchUcation collection

-

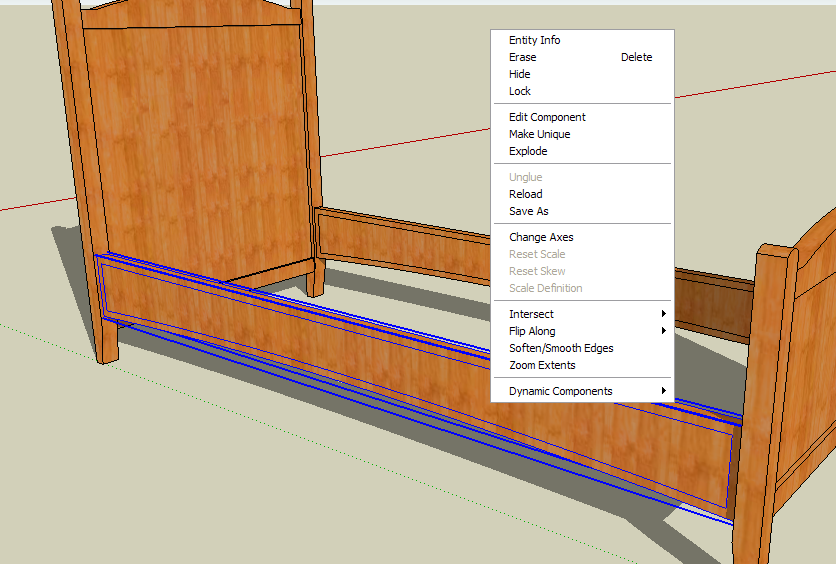

Why not fix the component axes on the bunk beds and bridge models?

-

Whilst on the subject of axis and material orientation I have noticed something since I recently started using Cutlist output and wondered if anyone has an answer.

It seems that SU treats length and width based on a convention of specifying the length as the longest of the axis, which is a problem.

For example in the attached file I have two panels (one being a streched copy of the other). When I look at the dimensions (in the Get Dimensions plugin or the Cutlist one) the dimension that SU treats as the 'length' is the Y axis on one and the Z axis on the other.

For material purposes, the grain will be shown correctly in the drawing, but any output will be incorrect as the grain should be running 'lengthways' (the Z axis in the example) in both and SU has swapped the length orientation in the larger panel2.

It seems that changing the axis has no effect on this and wonder if there is another setting I am missing which will take care of this issue.

If anyone knows the answer I would really appreciate a pointer in the right direction.

-

I'll have a chat with my friend who wrote the CutList plugin.

-

Thanks Dave.

I'd be interested in any thoughts he has.

However I don't think it is a plug-in issue.

I think it is the way that SU allocates its definition of length and width depending on which is the greater

-

You may be right on that. I sent him an e-mail and I will report ASAP.

-

Dave, I've never thougth about grain direction in but reading this topic I understand how important it can be. So, do you mean that you set the axis every time you make a component?

-

@brandy20 said:

Dave, I've never thougth about grain direction in but reading this topic I understand how important it can be. So, do you mean that you set the axis every time you make a component?

No I don't set the axis direction everytime I make a component. It is initially set automatically when the component is made and aligns with the global axes. People have problems with axis alignment when they make components in one orientation and then rotae them to put them in place. For example if you were to draw a skirting board for a table with it laying flat on the ground plane and then make the component before rotating and moving it into position between the legs, the axis alignment would be incorrect. I draw the parts in place in a project instead of moving the parts into place after drawing them. This reduces the work load and I don't have to be checking dimensions all the time. If the table legs are placed correctly for the size of the table, all I have to worry about with the skirting board is that it fills the space between the legs. I don't need to know how long that part is at this phase of the drawing. there's also no worries about accurately placing the component.

Sometimes though, the axis alignment does need to be corrected. As an example, draw a rafter board for a roof. Draw it in the orientation it would be in one the roof. Make that a component and apply a material to the faces of the component. YOu'll notice that on the sides, the material runs either vertically or horizontally depending upon the material's original orientation. Select the component and run cutlist on it while you're at it and see how much wood it says you'll need to make the rafter. Undo the material, correct the axis alignement for the component so that one axis runs along the long edge of the rafter. Now open it and apply the material. It may run across the side but it'll run at 90° to the side instead of vertically. This is quickly repaired by right clicking on the face, choosing Texture>Position, right click again and choose Rotate>90°. Run the cutlist again and you'll see you also get an accurate report of the amount of wood required to make the rafter.

Long winded. I hope it makes some sense.

-

@dave r said:

Run the cutlist again and you'll see you also get an accurate report of the amount of wood required to make the rafter.

The problem with cutlist is it ignores the x, y, z axis for determining the analysis of the parts.

For example:

Make a panel 500mm wide, 700mm high and 20mm deep. Run cutlist and the width, height and material thickness are correct.Now stretch the width to 1000mm and run cutlist again - you will see that the width and height are now reversed in Cutlist.

This makes it inaccurate for correct parts listing if you have a Dynamic component where the user can alter the width of the cabinet and does this so that the width starts at less than the height, but is enlarged to a width greater than the height.I wrote to the author about this, and he is considering changing the way cutlist determines the width and height based on the X and Z axis - when he returns to doing coding as he is busy elsewhere at present.

-

I understand your point. The flip side is that you can't count on people to draw things with the axes oriented correctly so just relying on the axes orientation in the component won't always work either. Still it's a good plugin.

Dynamic Components are problematic for some woodworking-related stuff too. For example, it would be nice to make cabinet door parts dynamic so it would be a quick thing to change sizes. If you want an accurate cutlist, you'd want the length of the tenons included in the rails and the length of the tongues on the edges of the panel as well. Resizing in Dynamic Components occurs via scaling. So making a door wider results in longer tenons which you wouldn't really do in practice.

You can split the rail component into three parts, the ends and a center. Then set up the DC so that the center section gets scaled and the ends get moved as needed. That prevents the tenons from being scaled but a cutlist will report three smaller pieces where there should only be one larger part.

Oh well, if it ain't one thing, it's your mother.

-

@dave r said:

You can split the rail component into three parts, the ends and a center. Then set up the DC so that the center section gets scaled and the ends get moved as needed. That prevents the tenons from being scaled but a cutlist will report three smaller pieces where there should only be one larger part.

I had this problem too - obviously 'cos that's how it works.

However, try adding a keyword (such as 'ignore') to the component name for the tennon parts, and then in the cutlist window add the word 'ignore' to the 'parts list box'. The parts are now ignored from the cutting info and added to the 'parts' table.

I raised this with the author who is also considering another request I made which will hopefully overcome this problem. That is to add a facility where certain key words are ignored from both the cutting list and the parts list.

@dave r said:

The flip side is that you can't count on people to draw things with the axes oriented correctly so just relying on the axes orientation in the component won't always work either. Still it's a good plugin.

I agree - it is a great plugin.

As far as the axis are concerned, it is a problem if people draw them incorrectly, but if the DC are already created (which I am in the process of doing) then hopefully it won't be a problem.

-

Dave, I understand your explanation, you talked about your technique in the cabinet project on th FWW blog. So it should be a quick job. I'll try it soon.

-

sorry guys, but I really can't get it! I can rotate the axex but I spent the entire evening in trying to rotate the texture!

This is what I do:

I choose the material, I apply it to the component and when I right click the mouse pointed on the texured face of the component I can't find the option Texture-rotate. Where am I wrong?

-

The problem is that you applied the material to the component's "wrapper". That's my term. When you apply the material, open the component for editing, first. Then apply the material to the faces. Select one face that needs to have the material orientation edited, right click and you'll find Texture in the menu.

See if that helps.

Dave

-

thanks Dave, tomorrow morning (it's late now here) I'll try to fix the problem. I'll give you the feedback.

-

Mission accomplished!

-

Good work!

-

To elaborate Dave's advice; you can only position a texture/material on a single face. "Not single faces" are (and the "Texture item thus doesn't even appear in the context menu):

[list:32expikr][:32expikr]groups/components - like in your case. Dave explained how to solve this.[/ 32expikr]

32expikr]

[*:32expikr]curved/smoothed surfaces - let them be "really" curved or even just coplanar with a softened, dividing edge (in fact, these edges should be deleted instead of being dealt with like below). With curved/smoothed surfaces however you can do the following- Go to View > Hidden geometry; this will reveal the "facets" building up a curved surface

- these facets can be manipulated like single faces - i.e. in this case you can position a texture on one

- Now select the Paint bucket tool and pres the Alt key > the tool will turn into an eyedropper/sampler tool

- sample the positioned material on the above "one" face

- Turn off hidden geometry (again; uncheck it in the View menu)

- Paint the whole, curved/smoothed surface with the positioned > sampled material.[/list

32expikr]Sounds to be a lot more complicated and longer than doing it with a little routine...

32expikr]Sounds to be a lot more complicated and longer than doing it with a little routine...

-

Good shot Gaeius!

I normally use the projection mode to texture curved surfaces and I'm going to try your method.

I normally use the projection mode to texture curved surfaces and I'm going to try your method. -

Projection is fast and handy but when the curve goes round too much, it is distorted on the sides. Or actually it is always distorted just in these cases it is too apparent.

With positioning however, though it may look "nicer", it is a bit tiresome. -

Actually I noticed that in a curved leg I made

Advertisement