Never posted any of my work here and thought some of you guys might like what I have done.

The bookcase is for a "foundation phase" reading room. The design specifically seeks to address a few of the shortcomings-to my mind anyway-of more conventional bookcases used in junior libraries:

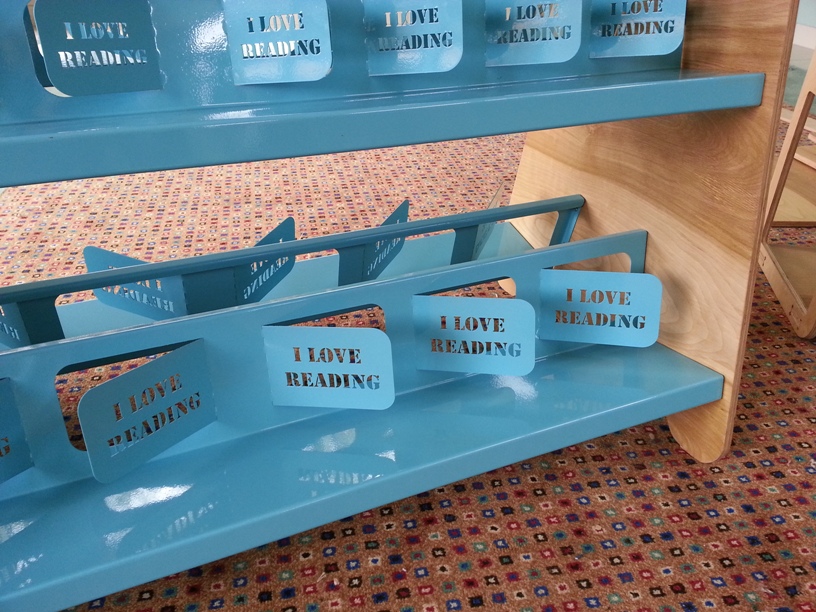

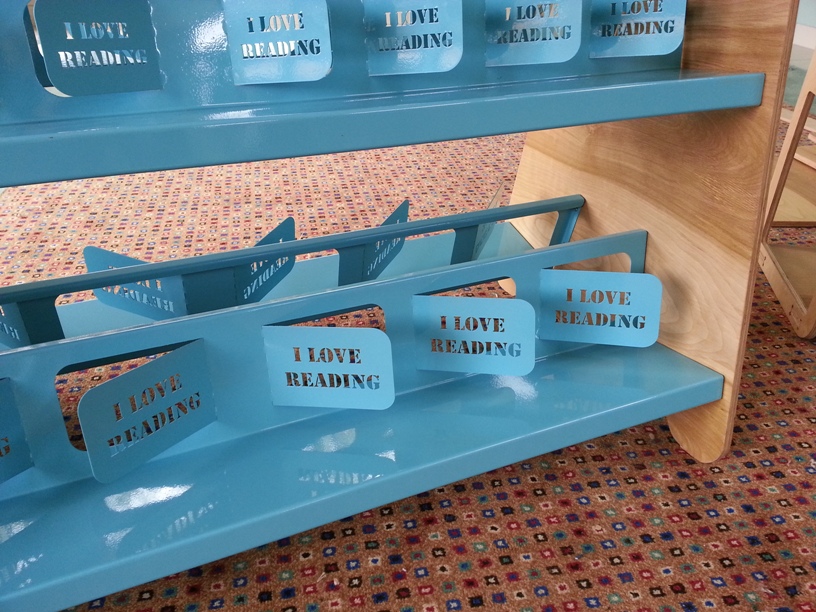

a)The kids who use this library are not interested in looking at the spines of books as they are just learning too read, they are drawn by the covers. The chances of a child finding a book that interests them is greatly increased by seeing more of the covers.

b)The school has an enormous number of books and therefore need a lot of storage but they only need the storage at the beginning and end of term when all of the books are out of circulation. During the school term most of the books are in circulation and the shelves would be empty in a conventional library-not very attractive.

c)A conventional bookcase construction usually requires a backing to keep it square under the loads it is put under. This ment kids were often obscured from the teachers view behind bookcases. It also made the space feel stuffy with large bland surfaces breaking it up. Using the mild steel for the shelves eliminated the need for backs.

d)One thing about all of the furniture I had seen before in libraries was how tacky they looked after a short while becuase labels applied to the surfaces were applied with "Prestic" or double sided tape leaving oily residues over everything. The steel shelves allow the use of cheap sheet magnets- which are printable -to denote categories etc. leaving no marks when moved around.

e)Lastly- i was able to manufacture and supply this bookcase at the same price as the conventional MDF "box" which was proposed. The plywood and pre-galvaised mild steel sheet are far more durable than MDF especially in the humid conditions we experience in Durban

Design was completed in sketchup, presented with layout, imported into Spaceclaim for sheet metal dxf files and Cnc routing files. My suppliers struggle with the segmented curves and holes that sketchup creates in dxf exports.